Valmet’s new premium calender covers – the ultimate high performers

Wear and impact resistance, as well as reliability, are entering another level with two newcomers to the Valmet Calender Roll Cover CL product family. In addition to graphical papers, they are suitable for specialty papers, as well as container and packaging boards.

The extensive development work Valmet’s R&D people have carried out to make the company’s premium calender roll covers even better and run even longer has resulted in two winning products. To tackle calender issues, the innovators have combined the highest wear resistance with the best load-speed durability and impact resistance in the new Valmet Calender Roll Cover CL-W and CL-S.

Thanks to improvements in material technology providing outstanding properties, these covers now offer the longest regrinding intervals in the most difficult calendering conditions in soft or multinip calenders.

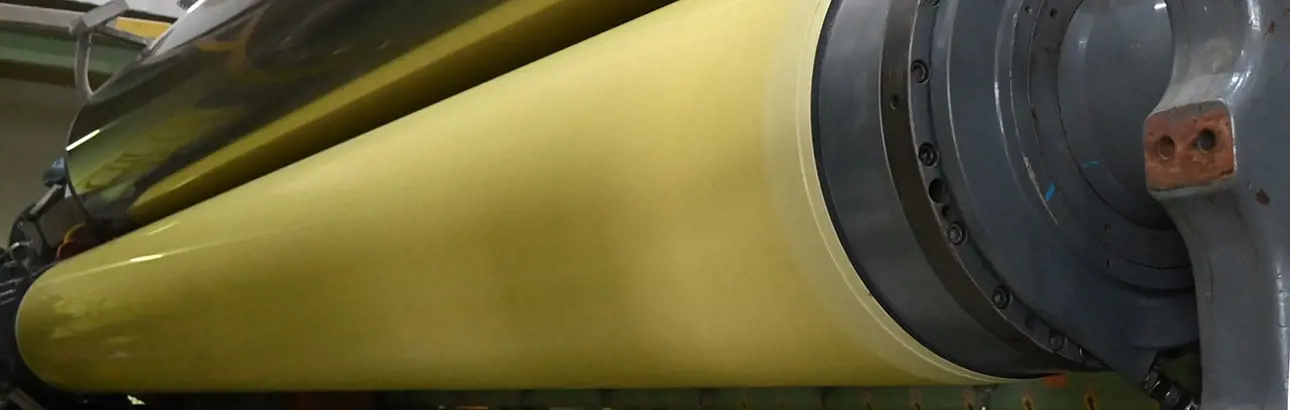

Longer runs, fewer roll changes, lower costs with Valmet Calender Roll Cover CL-W

Uninterrupted cover performance is something every board or paper maker is looking for. Valmet Calender Roll Cover CL-W fulfills this goal by featuring the best wear resistance, long running times and excellent barring resistance.

“In on- and off-line calendering, the cover running time is often limited by profile wear and sometimes also by barring. Wear resistance improvement has therefore been our main target in the development work. Calendering conditions are tough, and properties such as marking resistance and cover strength have therefore remained high with CL-W, making it a very durable cover,” says Tatu Pitkänen, Global Technology Manager at Valmet.

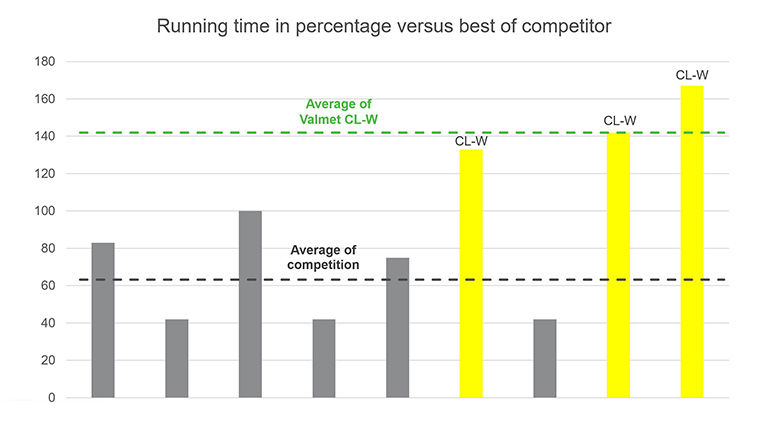

Proven results with Valmet Calender Roll Cover CL-W; longer roll changing intervals bring cost savings.

All this has been achieved by combining polymer technology with the latest material additives into a new formulation. As the CL-W cover features high wear resistance, there is less profile wear and susceptibility to barring.

“Paper and board makers can expect overall savings and the lowest lifecycle costs with CL-W thanks to its longer running periods, less need of roll replacement and grinding, and a longer lifetime. It provides a fast return on investment,” Pitkänen sums up.

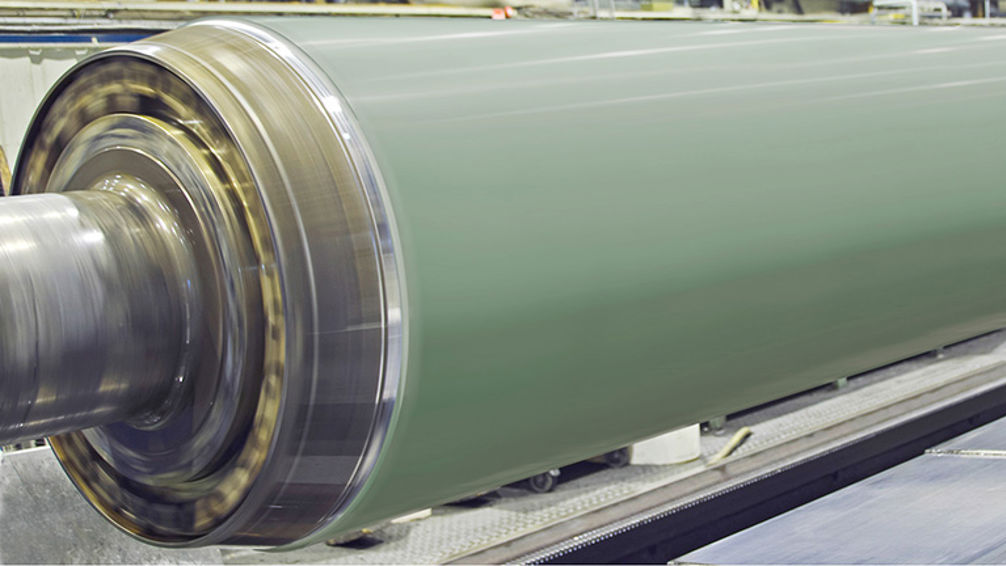

Roll changing intervals from days to weeks or months

CL-W’s exceptionally high wearing resistance has been proven in both laboratory and mill conditions. For example, at an LWC mill, a barring issue used to shorten the change interval of the first soft calender rolls to only two weeks, both with Valmet’s previous cover products and another supplier’s best covers. With CL-W, the change interval has been increased to around two months in the first nip without a barring issue and three months in the second nip.

At a WFU mill, the roll change interval of a soft calender was only about seven days due to a vibration issue with both Valmet’s and another supplier’s covers. With CL-W, the changing interval has been extended to 16–20 days.

A third case comes from an FBB mill, which often faced a 7–15-day roll grinding interval due to paper profile problems. In the first nip, the first CL-W running period extended to 54 days, and the second to 296 days, leading to CL-W repeatedly being the next recovering choice.

CL-S has the best impact resistance

Valmet Calender Roll Cover CL-S has been developed to further improve robustness and offer the best impact resistance for the most reliable runs in harsh conditions without dents or cracks.

“Calender covers suffer from problems caused by impacts due to dirt or sheet breaks. These issues can lead to unplanned roll changes and quality defects in the paper or board. This is why impact resistance improvement is so important,” explains Rob Stapels, Global Product Manager at Valmet. “Our R&D has combined polymer technology with the latest material additives into a new formulation to improve the composite structure’s impact strength. This boosts both impact resistance and elasticity, reducing the risk of sudden cover damage, dents or cover surface marking.”

Valmet Calender Roll Cover CL-S is designed to withstand abuse in the calender.

“The new material technology thus provides the best durability under web breaks or other sudden impacts. The new soft cover also allows a smooth, elastic, long-dwelling nip for optimal paper quality characteristics for bulk saving, for example.”

Stapels continues: “A longer running interval stands for reduced costs. Although the purchase cost of this premium cover is slightly higher than that of standard covers, its lifetime cost is much lower given longer running periods, less need of roll replacement and grinding, and a longer lifetime.”

A longer lifetime was proven, for example, at a SC-A paper mill that suffered from repeated cover damages due to high nip stresses from a high nip load combined with small roll diameters. When a relatively soft but tough and durable CL-S was introduced to both the deflection-compensated and intermediate rolls, the mill could run the rolls longer.

Expectations met and exceeded

The above shows how CL-W and CL-S take calender roll covers to the next level with their extremely high wear and impact resistance, as well as reliability. These covers have constantly met and even exceeded the expectations in customer calenders – regardless of the paper or board grade.

Valmet Calender Roll Cover CL-W performance – the winning choice against any competition.

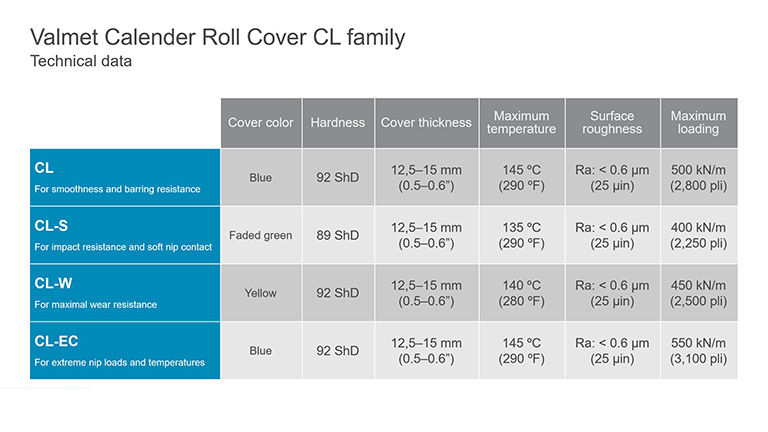

The Valmet Calender Roll Cover CL product family – leading choices for all graphical and specialty paper and board calendering.

Text: Marjaana Lehtinen