Roll types for pulp drying

Latest roll technology innovations for high operational reliability

High quality rolls for maximum performance

Optimal runnability

Highest durability for long roll change intervals

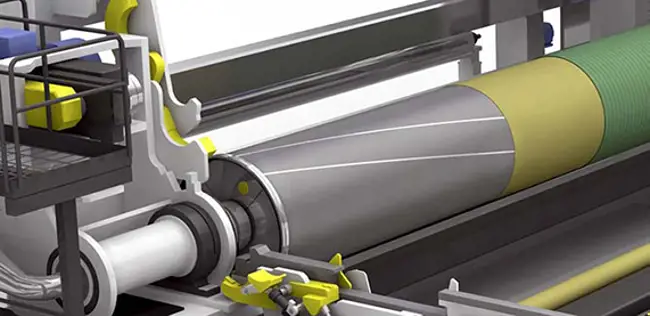

Suction rolls

Suction rolls provide high performance on all types of pulp drying machines. Aside from rolls for Valmet machinery, we can also offer appropriate spare rolls for a number of other makes. Many of our latest roll technology innovations can be adapted into spare rolls that are compatible with existing rolls. This is an easy and cost-effective way to improve suction roll performance.

Spare suction roll shells

Suction roll shells are made of the highest quality Duplex stainless steel shell blanks manufactures through a plate hot rolling or centrifugal casting process. Precision drilling ensures extremely accurate hole positioning and superior hole surface smoothness.

Services for suction rolls include:

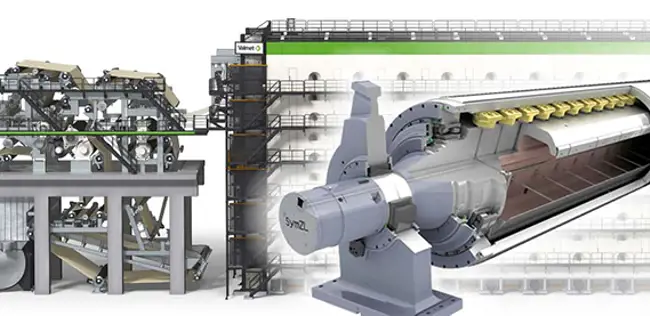

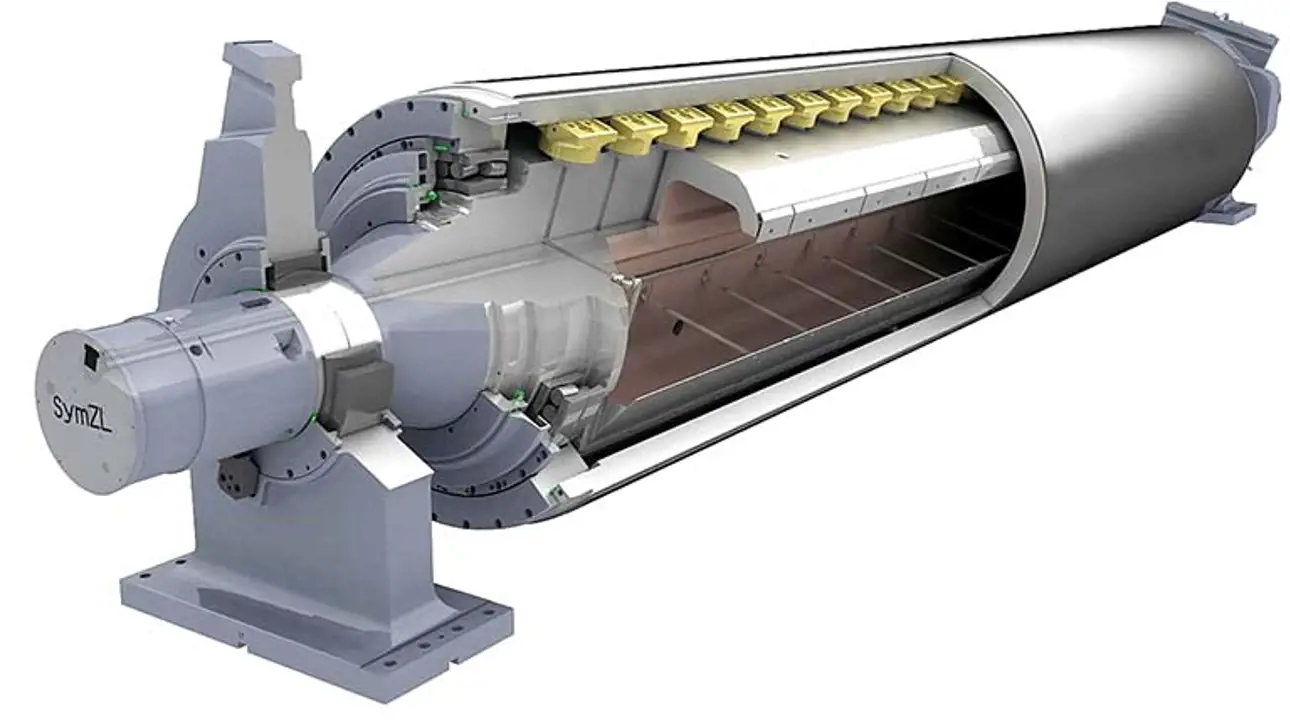

Deflection-compensated rolls

Deflection-compensated rolls provide reliable and stable operation. These rolls are the key elements for efficient pressing and dewatering.

- Valmet SymZL Shoe Press Mating Rolls

- Valmet SymBelt Shoe Press Rolls

Services for deflection-compensated rolls include:

- Shoe type roll maintenance

- Proposal to improve performance with upgrades

Questions?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

CONTACT US

The shoe press bottom roll is the key equipment of our pulp drying machine, and it was a restricting factor for our entire mill. Based on the current situation, its performance meets our expectations,” says Yajun Sun (left) Pulp Making and PDM Facility Manager, Juntai Technology.

High-precision tube rolls

Well-performing tube rolls are essential for pulp drying line runnability. High reliability and easy repairability in the case of accidents are also important requirements for these rolls. Valmet’s high-precision tube rolls with optional quick change heads were developed to meet these specific demands.

Articles and references