Workshop services for cooking and fiberline

Services for high reliability and improved performance

Good reliability, high performance and spare unit availability are all key requirements for cooking and fiberline equipment. Cooking and fiberline equipment need periodic reconditioning, and guaranteed availability and spare arrangements are needed, for example. Scheduled equipment maintenance in workshops also offers a great opportunity for various upgrades to take the equipment features to the next level.

Ensure high operating reliability

Optimal performance and production

Guaranteed availability with optimal cost

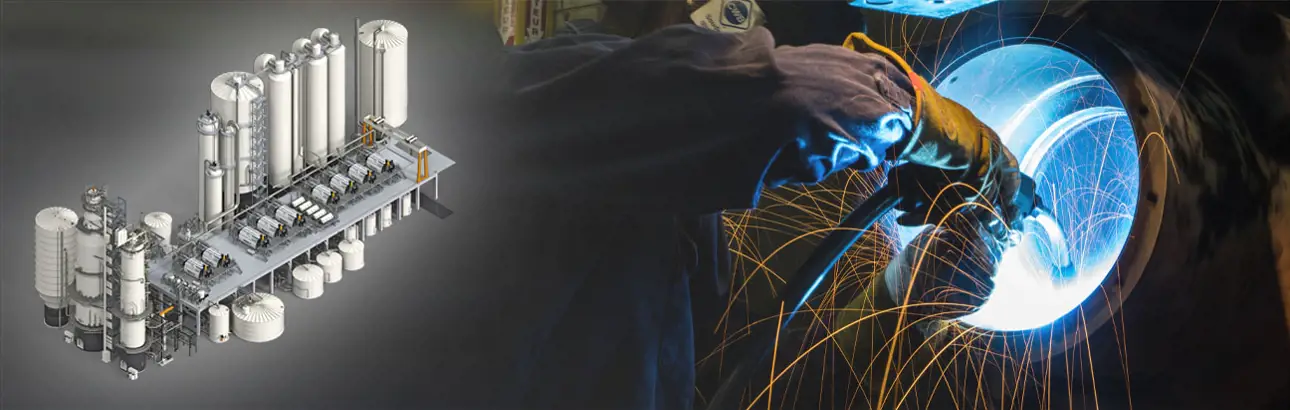

Workshop services for cooking

The performance and reliability of the chip feeding equipment are essential for an efficient cooking process. Key equipment like low/high pressure feeders and top separators needs a periodic reconditioning service to keep it running and producing. Scheduled equipment maintenance in workshops also offers a great opportunity for various upgrades to take the equipment features to the next level. Upgrades such as improved components or remote control and monitoring systems offer maximized reliability and opportunities for process improvements.

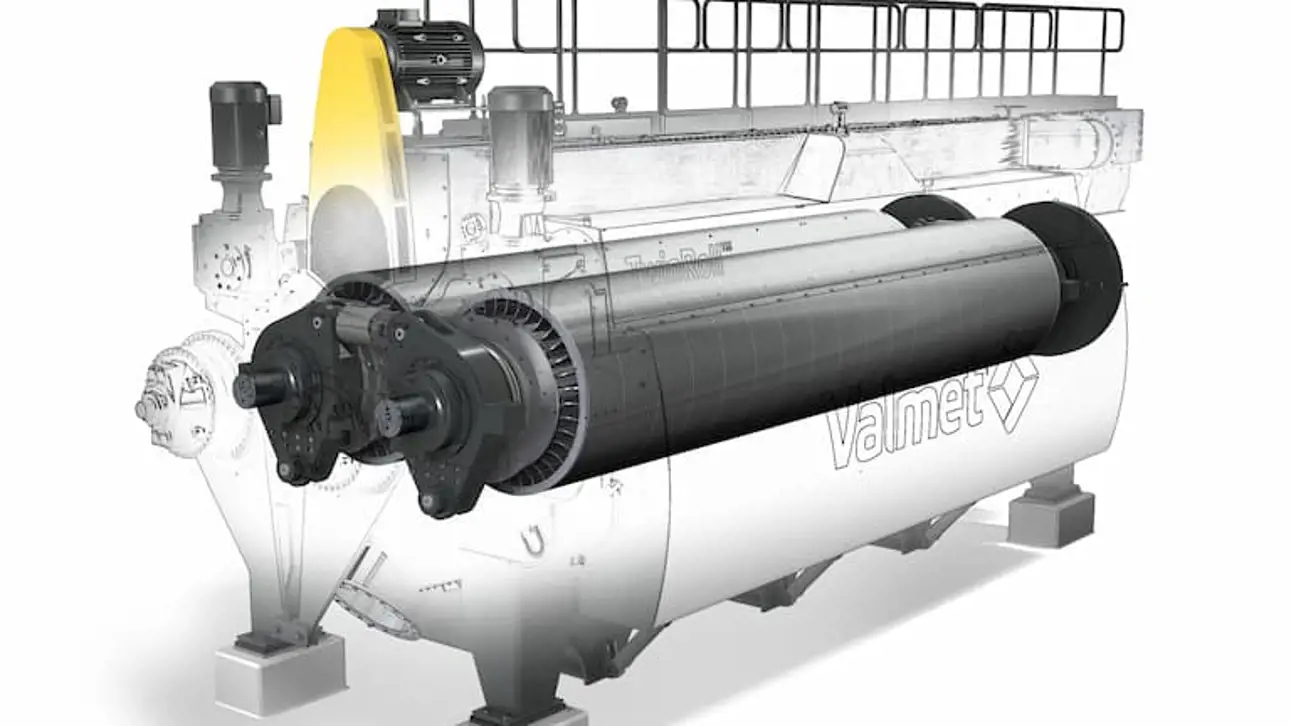

Workshop services for fiberline

Valmet’s TwinRoll Presses represent the most advanced pulp washing technology, which meets the highest requirements to ensure reliable production with optimal performance and the cost-effective availability needed in the fiberline.

Rolls in TwinRoll Presses need periodic reconditioning, and spare roll arrangements are needed for guaranteed roll availability. Valmet offers a full range of workshop services for rolls in TwinRoll Presses: reconditioning services; roll upgrades; new spare rolls; and Exchange Unit Agreements.

Questions?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

CONTACT USMonitoring services enabling predictive equipment maintenance

Remote monitoring tools offer great help when deciding maintenance schedules for equipment requesting workshop repairs. Sometimes monitoring tools even reveal machine defects that could cause unexpected catastrophic equipment failures. Most tools can be also utilized for process optimization purposes.

Valmet has developed and constantly develops new sensors and measurement solutions for signals which have been hidden before. Equipment repair offers good moment to get it connected for visibility.

TwinRoll Press services

Continuous technical developments and improvements in materials and design make the reconditioning of press rolls a profitable investment that will repay itself in maximum service life, availability and performance.

Scope example of the typical service:

- Fixed price for normal reconditioning of standard roll

- Minimal repair time with spare parts from stock

- Upgrading of all parts to latest design

- Report, including recommendations

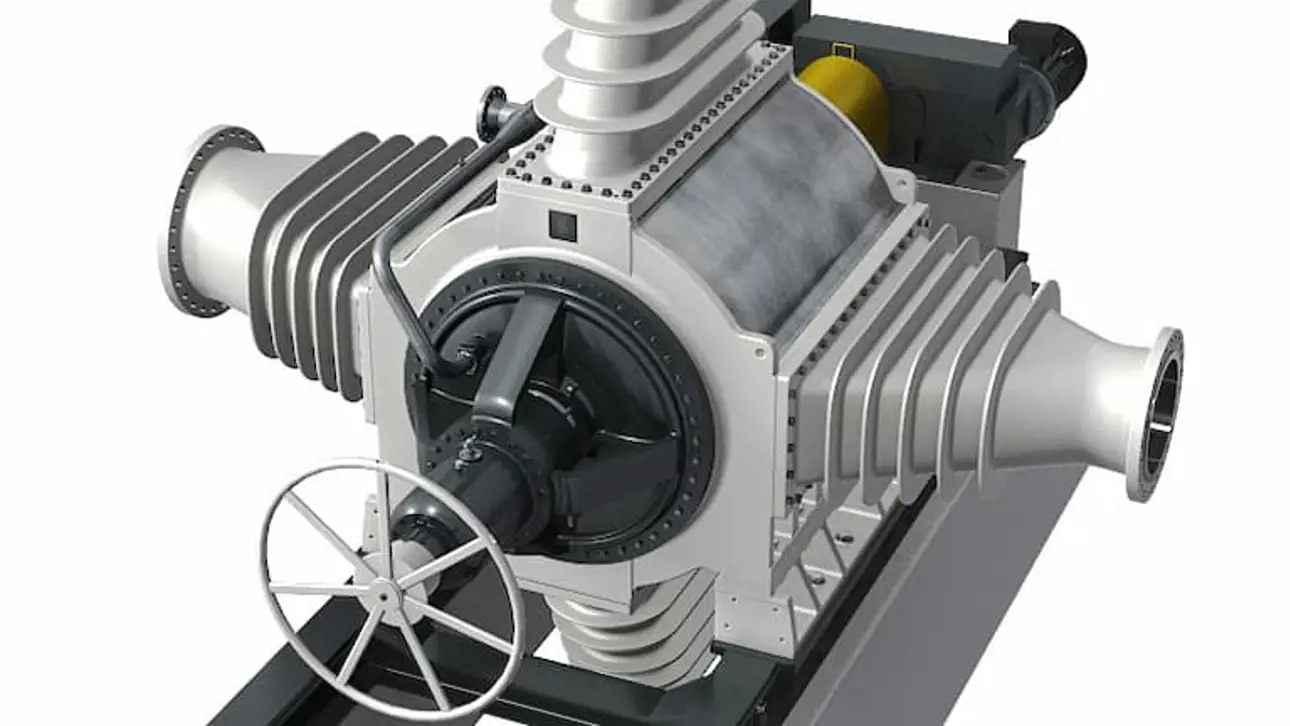

High- and low-pressure feeders

Recondition work follows the same stringent requirements as for manufacturing new feeders.

When choosing Valmet for your feeder recondition needs, we will ensure each case is properly analyzed, recommendations are reported, and that the final recondition scope is thoroughly discussed when your requirements have been met.

Learn more about our latest innovations:

Exchange Unit Agreement – a powerful risk management tool

It can be difficult to find a balance between risks and costs in the spare equipment inventory. Valmet’s Exchange Unit Agreement is an alternate solution that eliminates the need to purchase your own spare equipment. The agreement ensures dedicated equipment in perfect condition is always available to the customer. Agreements are established based on each customer’s needs. They are powerful risk management tools, with known annual costs.

References and articles

Related pages