Spreader rolls for board and paper machines

Wrinkle-free operation for optimal paper quality

Spreader rolls ensure wrinkle-free board or paper quality and equal tension-profiles for paper sheets and fabrics. Valmet offers spreader rolls suitable for all applications in the paper industry where there is a requirement to eliminate creases and wrinkles from the material being processed or to prevent interweaving of slit widths of sheet in the winder application.

Removing wrinkles from sheets and fabrics

Correcting tension profiles

In winder to prevent interweaving of slit sheets

For high quality paper

In an industry striving to perform and bring top-quality paper to the market, well-known issues like creases and wrinkles in the paper and board can cut down production and impact machine efficiency. Valmet brings its expertise in spreader roll technology to help you overcome these issues and provide safer and more efficient production.

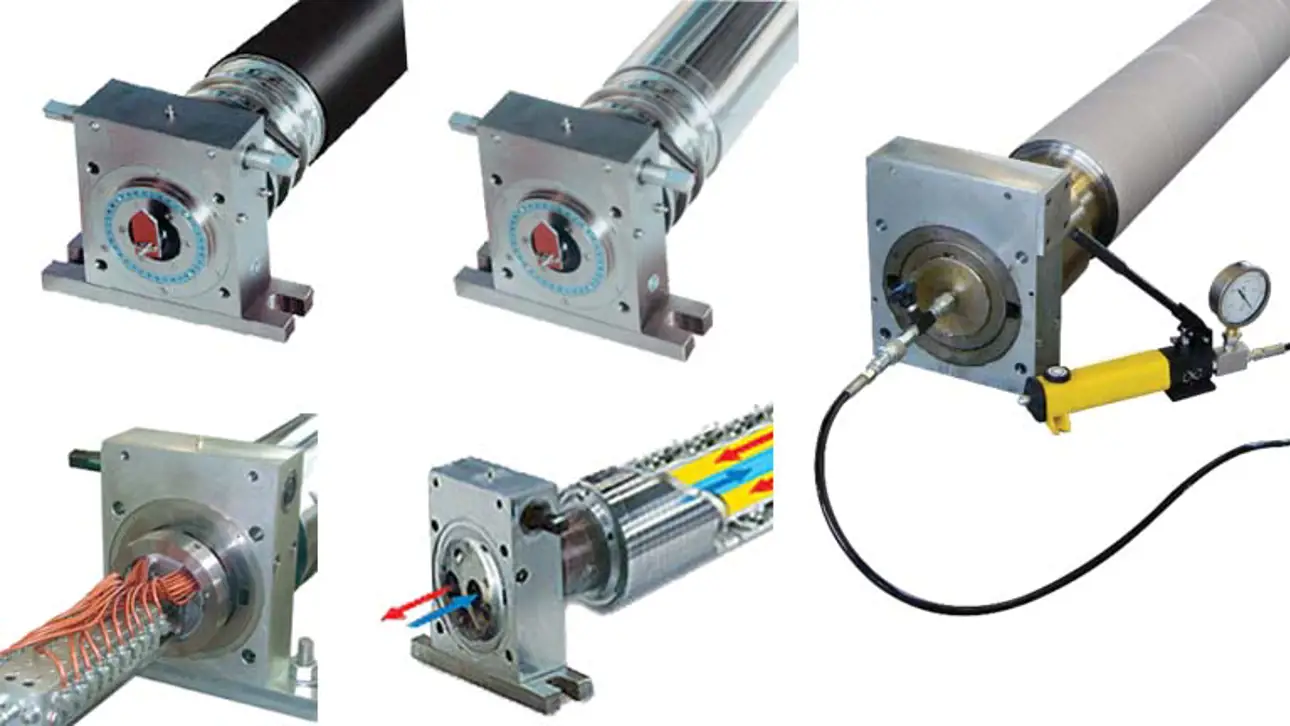

Valmet Spreader Roll M (available globally, excluding NA)

- Spreader rolls with steel spools (+ optional hard coating)

- Spreader rolls with rubber sleeve

- Options:

- Adjustable bow amount

- Centrally lubricated bearings

- With axle cooling

Valmet spreader roll offering (only available in North America)

- Metal spreader roll - ideal for applications which require high wear and temperature resistance

- Rubber spreader roll - used in many machines sections and is especially appropriate for high moisture applications

- Spreader roll with adjustable bow - allows operators to change the roll bow amount while the machine is running

- Spreader roll with centrally lubricated bearings - ideal for high speeds and high temperatures

- Spreader roll with axle cooling - ideal for high temperature applications such as coating stations, size presses andespecially positions near to IR dryers

80 spreader rolls delivered