Reel audit leads to increased tonnage on fine paper machine

Dec 15, 2020

A well-functioning reeling process is necessary for good paper roll quality and the elimination of reel broke. Reeling process reliability and runnability are ensured by periodic maintenance of the reel. This includes various actions in response to the tests and inspections to improve the performance of reel equipment.

The mill was established in 1890. The facility included a kraft pulp mill producing hardwood and softwood pulp. The complex produced over 300,000tons/year of paper on three papermaking machines.

No. 12 PM was a Valmet fine paper machine, installed in 1981. It had a sheet width at the reel of 300 inches and a design speed of 3,500 feet/min. The machine was used to make uncoated and carbonless base stock grades.

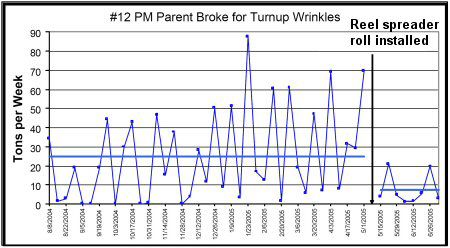

"The main issue we were struggling with was turn-up wrinkles in the primary arm position while on heavyweight grades," said the mill representative. "We were needing to add approximately 5,000 feet of paper to each reel because of the issue. That 5,000 feet closest to the reel spool was then slabbed back off at the winder as broke," he said.

For help in further reducing the wrinkling problem, "We turned to our Valmet mill representative and asked about what resources were available through Valmetto help diagnose the problem," he said. "He suggested a machine audit [process and condition test (PACT)] and we agreed that the audit should give us a list of additional areas to look at and Valmet's current thinking around reel designs."

A reel audit by Valmet identified specific problems and solutions that would improve reel performance. The audit is a very popular test, said Valmet's Business Manager for reels, "We call the customer, discuss the set-up process, and try to schedule the audit around a one-day shutdown," he said.

"Usually we have a one-hour meeting at the mill before the audit begins," he explained. "We plan three days, if possible, to gather information. That includes one day while the machine is running and one day while it’s down. Later, at the end of the PACT there’s a three-hour meeting with mill staff to review the results."

"The audit gave us another pair of eyes looking at the issues," the mill representative said. "We also relied on the expertise of those involved in the audit as they see quite a few more machine situations in their jobs. They can bring that learning to the table."

After conducting the audit, a Valmet service representative prepared a technical report that presented specific findings and recommended corrective actions. He also prepared a list of 16 repairs and changes that would improve the reel's performance. The chart included the anticipated benefits and budget for each item.

In his report, the process specialist suggested several steps the mill's maintenance staff could take to improve reel performance:

- Tune the reel drum drive for more stable tension during the turn-up sequence

- Repair bent reel spools

- Adjust secondary arms synchronizing shaft to allow for more free play

- Straighten the pulper guard under-reel

- Reduce the reel drum doctor oscillation

- Correct inaccuracies in the draw display at the operator panel.

In addition, he suggested the following actions Valmet could perform to improve reel operations:

- Add hydraulic relief cylinders to the primary arms

- Upgrade locking clamps and increase loading force in primary arms

- Replace primary arm bushings

- Add adjustable coupling to the primary arms synchronizing shaft

- Replace primary arms turning motor with a variable speed motor

- Install proportional valves to control primary and secondary arms loading pressures.

The mill decided the solution to the problem was to replace the undriven, straight paper carrying roll located before the reel with a driven, bowed roll. They also decided to replace the worn primary arm clamps with the improved design that would hold the mandrel in place better.

The roll - installed in early 2005, during the annual shutdown - performed as expected, according to the mill. The new primary arm clamps hold the reel spool in alignment throughout its travel and the new spreader roll has proven to be a valuable tool for the operators to use for optimizing reel build.

Adding a bowed spreader roll and replacing worn primary clamps significantly lowered broke due to turnup wrinkles.

"We have achieved the original project goals and no longer add additional footage to our reels for turn-up wrinkles," the mill representative said. "The operations and maintenance folks are pleased with the project."

Because of the improvements, the mill was able to sell an additional 18 tons of paper per week that had been going to broke.

For more information about improving your reel operations, contact your Valmet representative and ask about a reel audit.