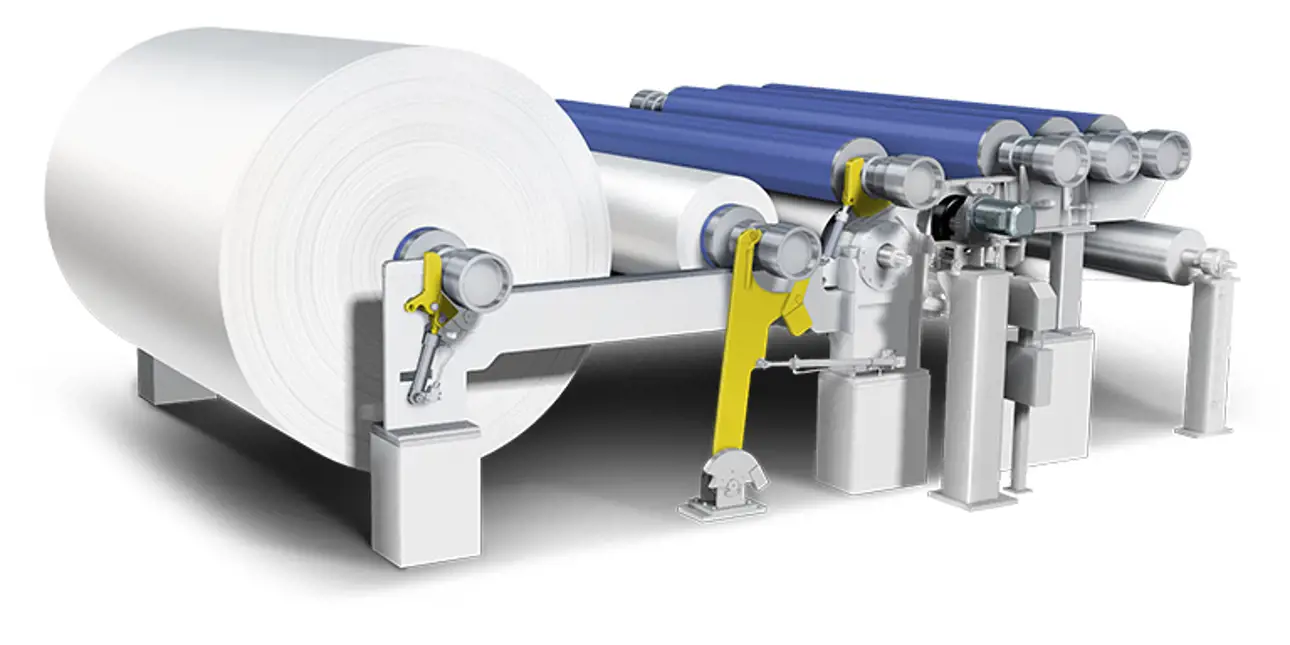

OptiReel Pope and OptiReel Linear

Reels without center drives: The reeling workhorses

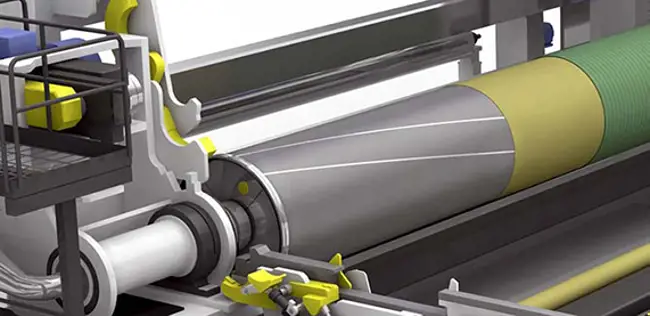

OptiReel Pope and OptiReel Linear without center drives are Valmet’s standard reels. They provide just the right level of reeling technology required by grades and operations with less demanding reeling conditions. They are especially suitable for containerboard and uncoated fine paper grades.

Compact layout, easy to install in existing production lines

High turn-up efficiency

Proven technology and components

Clear user interface

Compact layout

As Valmet's reels without center drives have a compact layout, they are easy to install in existing production lines. Discover more about OptiReel Linear.

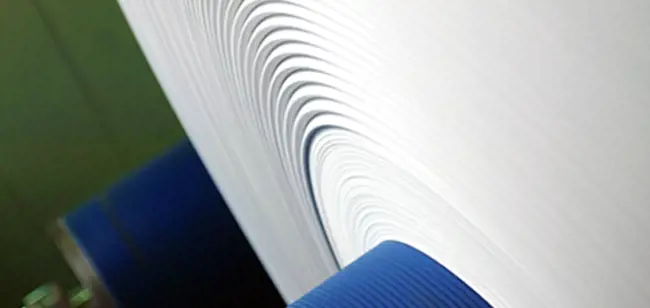

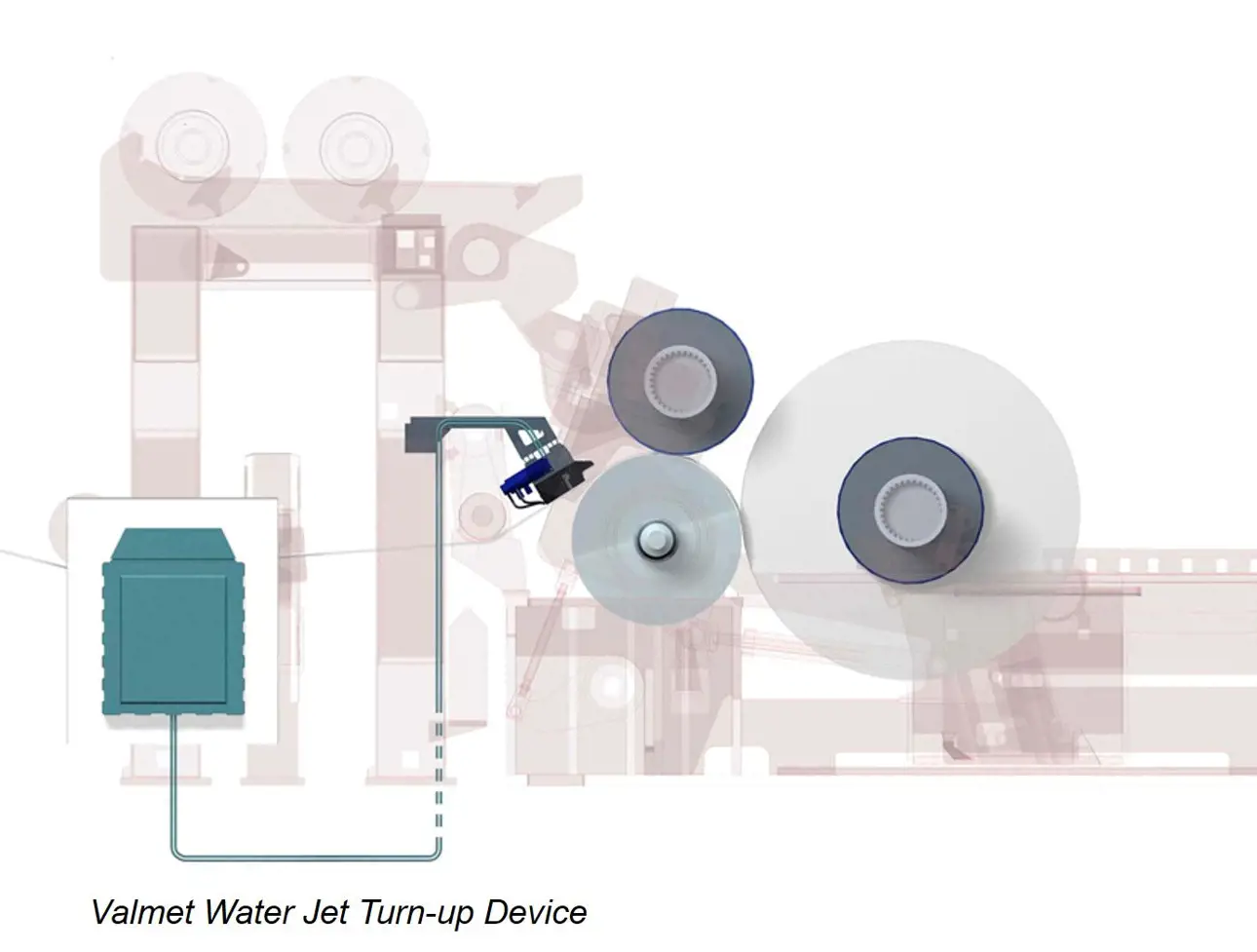

High turn-up efficiency

As for all Valmet's reels, the turn-up efficiency of reels without center drives is very high - even as high as 99 %. The parent roll changes are made quickly and cleanly. There is a significant reduction of reel bottom waste with this completely automatic turn-up operation.

Want to talk to our reeling experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsProven technology and components

You can rely on OptiReels without center drives:

- The technology used in is highly proven with numerous references all over the world

- No compromises have been done with the components used to meet the high requirements of Valmet's reel.

Clear user interface

OptiReels without center drives are easy to use. The reels are rebust and their user interfaces are clear.

Interested in pilot trials?

Get in touch with our pilot trial experts to discuss how you could benefit from our pilot trial services.

Contact our pilot trial expertsHow to plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. Download our e-book to learn more.

Download e-bookPlanning a grade conversion?

The world is changing fast; the consumption of papers is decreasing and boards increasing. Update your paper machine with Valmet to produce more profitable products.

Discover moreLearn more about the services and automation solutions for reels

Explore our latest board and paper press releases

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China

- Oct 4, 2023Valmet introduces a new rotating consistency measurement for pulp and paper producers

- Sep 26, 2023Valmet to supply a fine paper making line to Yueyang Forest Paper in China

- Aug 31, 2023Valmet to supply key pulp and paper technologies to Naini Papers in India

- Jul 19, 2023Valmet to supply a high-capacity winder to Gascogne Papier in France

- Jul 4, 2023Valmet to supply an OptiFlo headbox and Valmet Conical Refiners to Shree Ajit Pulp and Paper Limited in India

- May 8, 2023Valmet to rebuild ITC’s board machine in India

- Apr 25, 2023Valmet to deliver key technologies for Henan Longyuan Paper’s testliner line in China

- Mar 27, 2023Valmet to supply a new container board making line to DS Smith in Italy