OptiCoat Jet coating

Uniform and skipfree coating

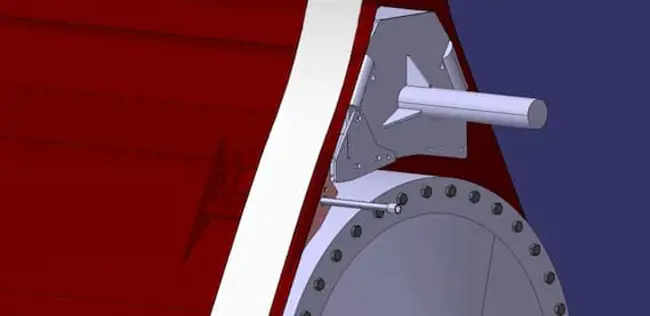

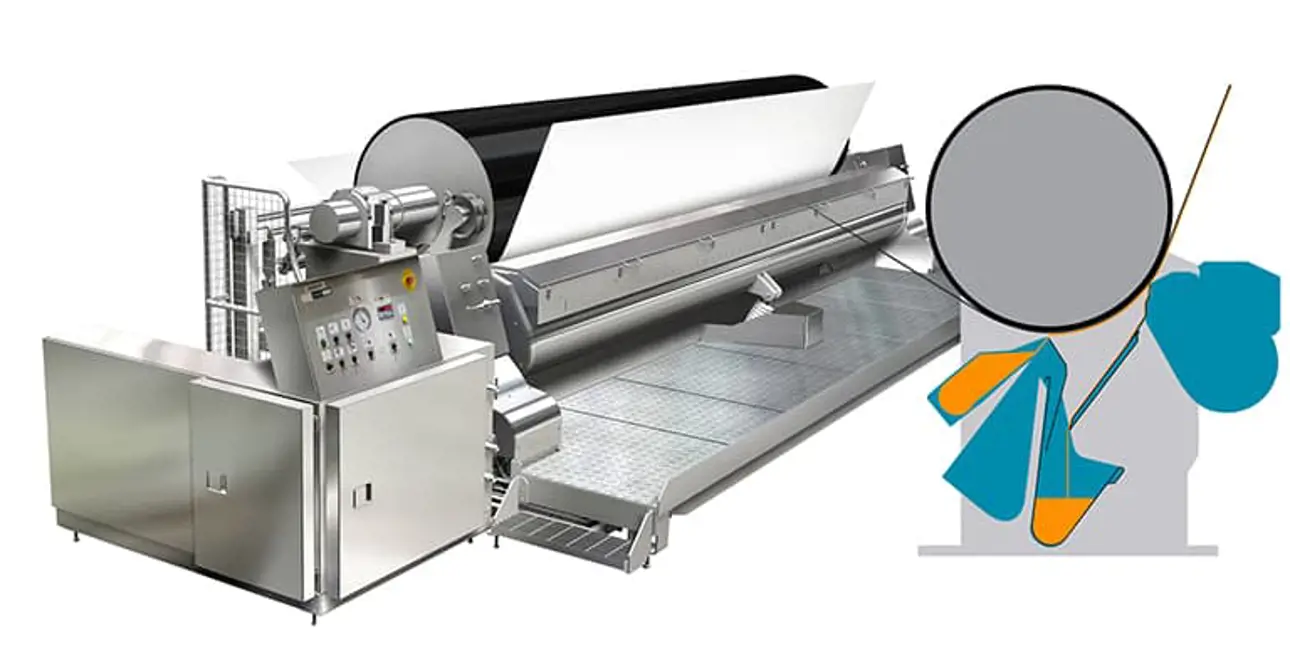

OptiCoat Jet coating provides very uniform and skipfree coating quality. It gives the best possible surface smoothness compared to any other coating method. OptiCoat Jet coating station applies a surplus coating layer to paperboard surface with jet nozzles. The excess coating is scraped away by metering blade and returned on a return plate to the color collection pan. The desired coatweight is achieved by adjusting the angle or pressure of the blade. The impingement pressure is maximized with closed nozzle geometry.

Uniform coating quality

Fast start-up and web break recovery

Easy maintenance & operation

Excellent runnability

Uniform coating quality

OptiCoat Jet produces high quality coating on paper and board in both cross and machine direction. High quality backing roll is one of the reasons for reduced MD coatweight variation. Skipfree coating is a result of a very effective de-aeration in color circulation. The application method and cross direction control capabilities are important for uniform application and excellent CD profiles.

Fast start-up and web break recovery

All Valmet coating stations are fully pretested in workshop. The instrumentation and controls are integrated in the machine and all the controls located by the station frame. The interface and automation systems are user-friendly. After web breaks, coating can be re-started fast. Tailthreading is fast and reliable. A wide operating window enables good surface quality almost immediately after the coating is started.

Want to talk to our coating experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsEasy to adjust, operate and maintain

Because of a wide operating window, coating quality is easily maintained high when speeding up the machine. The wide window and operator friendly automation facilitate finding the correct parameters for each paper or board grade. Clean coating process and easy wash-up speed up the maintaining operations.

Excellent runnability

Jet application is contactless resulting less breaks. Runnability is also improved because of a smaller doctor blade load compared to other application methods. Jet application also has excellent efficiency even at very high speeds.

Interested in pilot trials?

Get in touch with our pilot trial experts to discuss how you could benefit from our pilot trial services.

Contact our pilot trial expertsPlanning a grade conversion?

The world is changing fast; the consumption of papers is decreasing and boards increasing. Update your paper machine with Valmet to produce more profitable products.

Discover moreHow to plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. Download our e-book to learn more.

Download e-bookLearn more about the services and automation solutions for coating

Explore our latest board and paper press releases

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China

- Oct 4, 2023Valmet introduces a new rotating consistency measurement for pulp and paper producers

- Sep 26, 2023Valmet to supply a fine paper making line to Yueyang Forest Paper in China

- Aug 31, 2023Valmet to supply key pulp and paper technologies to Naini Papers in India

- Jul 19, 2023Valmet to supply a high-capacity winder to Gascogne Papier in France

- Jul 4, 2023Valmet to supply an OptiFlo headbox and Valmet Conical Refiners to Shree Ajit Pulp and Paper Limited in India

- May 8, 2023Valmet to rebuild ITC’s board machine in India

- Apr 25, 2023Valmet to deliver key technologies for Henan Longyuan Paper’s testliner line in China

- Mar 27, 2023Valmet to supply a new container board making line to DS Smith in Italy