Press roll covers for tissue machines

Improved machine runnability with press roll covers

In tissue machines, pressing is a very brief and compact yet vital process for effective water removal. It thus places great demands on the durability, maintenance costs and energy consumption of the roll covers in the press section.

Improved dewatering

Better dryness and runnability

Optimal tissue quality

Improved dewatering with press roll covers

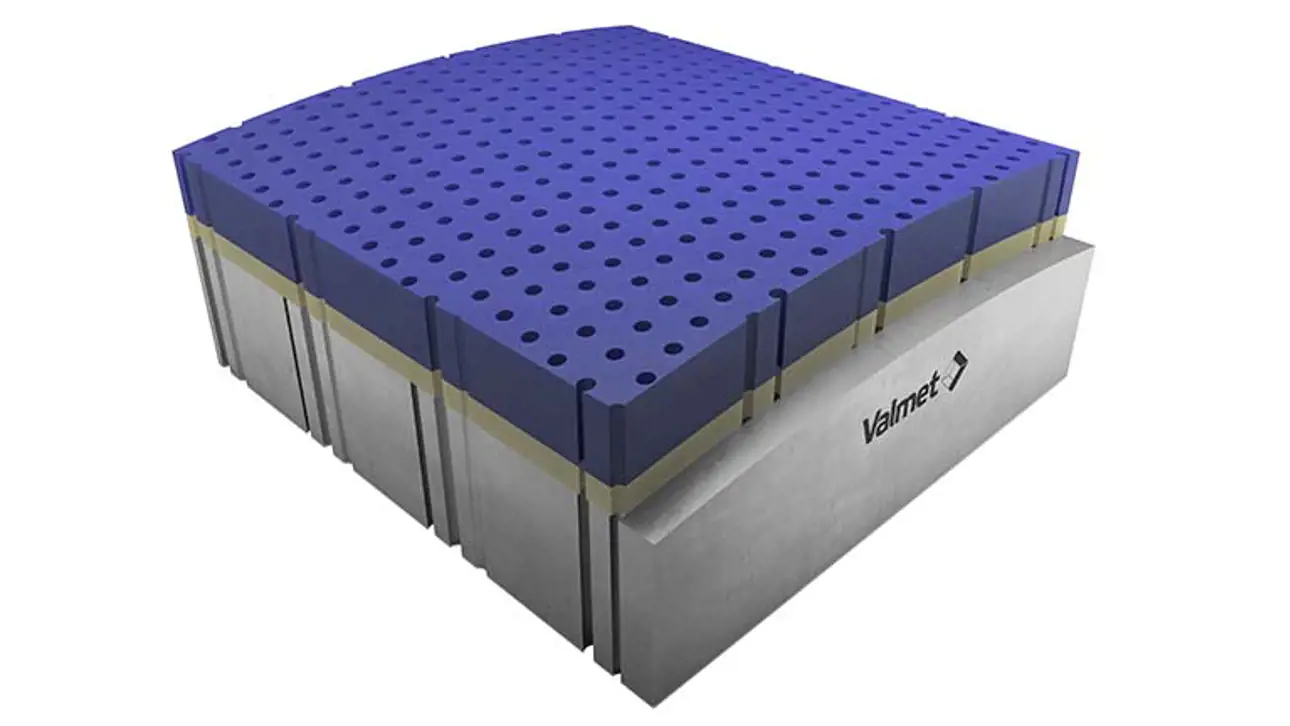

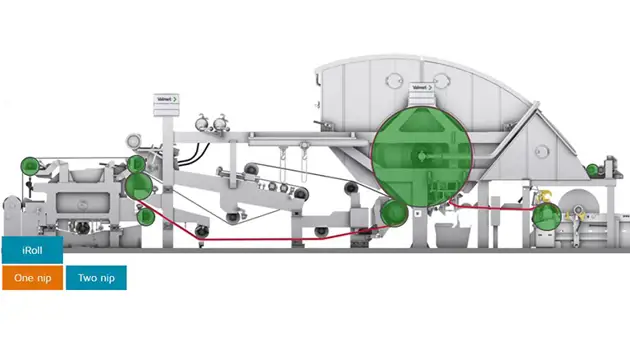

Valmet offers a wide range of roll cover solutions with advanced dewatering technology for different tissue presses and roll positions. Valmet Press Roll Cover PH and Valmet Press Roll Cover PL, our latest innovations for press and suction rolls bring energy savings in tissue production with efficient dewatering. The exceptionally wide hardness range design of Press Roll Cover PL enables an adaptive roll cover structure and thus better final product profile and bulk savings.

Our selection ranges from economical rubber covers for less demanding applications to state-of-the-art polyurethane roll covers that ensure improved press nip loading and constant operating parameters in demanding pressing conditions.

Better dryness and runnability with Doctor Blade Dual

The press section also has a major impact on sheet surface properties such as tissue bulkiness and thickness. Achieving the desired tissue quality depends on water removal efficiency and the roll covers' uniform properties. In addition to press roll covers, Valmet offers solutions for better dewatering and sheet dry content with Doctor Blade Dual, a doctor blade with two patented functions that solves roll doctoring problems in challenging press section positions.

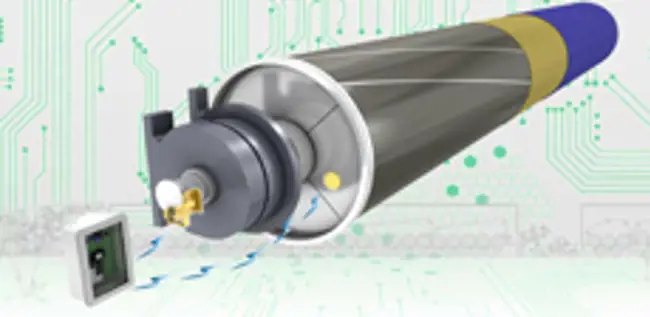

iRoll Press improves nip profiles and runnability

Runnability and quality defects due to press nip profile variations cause problems with sheet quality and water removal, as well as increased energy consumption. Valmet iRoll Press creates new options for improving press function and offers a solution to these problems. In addition to improved press nip loading, iRoll Press offers an extended roll cover lifetime and smooth runnability.

Find optimal roll covers for tissue making

Browse this roll cover application tool and easily discover different cover options for your pressing applications in the tissue machine.

Start exploringArticles and references

keyboard_arrow_leftBack

{{currentHeading}}

{{productForm.Name}} {{"("+productForm.Size+")"}}