Success with remote commissioning and start-up support in Ilim Bratsk Evaporation project

Aug 17, 2020

When there’s a will there’s a way – Valmet’s Evaporation project team together with specialists from Ilim Group’s Bratsk mill found new ways to collaborate remotely during commissioning and start-up phase.

Valmet delivered a new Evaporation line to Ilim Group’s Bratsk mill located in Irkutsk Oblast in the middle of Siberia in Russia. The erection works were completed in spring 2020 and the start-up in early July 2020.

New Valmet Evaporation System at Ilim Group’s Bratsk mill (Russia)

During the spring, it was time to start the commissioning works, the global coronavirus pandemic threw a curveball to the team with borders closing and travel to the site becoming impossible.

“We had a Russian E&I advisor and a DCS expert onsite, but we needed to quickly find a way to support the customer to be able to supervise the commissioning and start-up phase. Through joint efforts together with the Ilim team, such a way was found,” tells Valmet’s Project Manager Sven Lennartsson.

Valmet set up a commissioning team located in Gothenburg, Sweden with a meeting room turned into a remote control room. As the mill is located in eastern Russia, just north of Mongolia, with a six hours’ time difference, the team worked initially from 2 a.m. to noon Swedish time, to be able to work at the same time with the customer. In June, to prepare for the start-up, the team moved to 24/7 remote support.

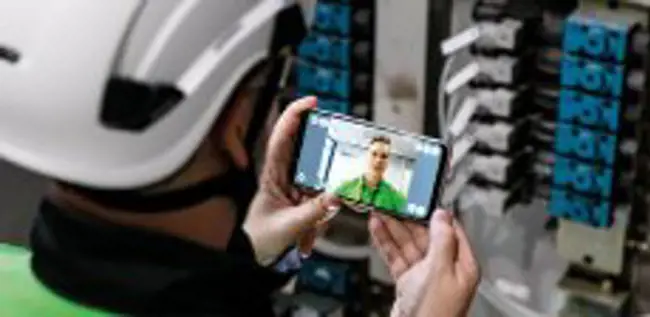

“During the commissioning phase we planned the steps and sent customer tasks for the coming few days, and the customers’ mill team did the work onsite. We had daily Teams meetings with the site, and the mill team reported back on what they had done. We received a lot of photos and videos from the site. Additionally, we had access to the DCS system to have access to the complete data of the mill. The last weeks before the start up we worked very intensively together. Once the hot commissioning started, we tested the equipment and finetuned it for the start-up. The remote connection to the DCS system was especially valuable in this phase,” tells Tommy Lundin, Valmet’s Commissioning Manager.

Bratsk remote support team in Gothenburg (on left) and team at the Ilim Bratsk mill (on right) worked seamlessly together.

“Being onsite is important, but this has actually worked quite well – much better than we expected. The key to successful cooperation has been the very skilled and professional mill team, and the possibility to get photos and videos from the site – and naturally a working internet connection,” the team explains – completing each other’s sentences.

“We were all committed to a successful outcome. We worked closely together with the Ilim team and had common goals for secure a successful start-up. The successful start-up was achieved with dedicated professionals on both sides, good communication and mutual trust,” Sven Lennartsson concludes.

About Ilim Group and the project:

- Ilim Group is the biggest Russian pulp and paper producer, which produces over 75% of market pulp in Russia, 20% of board, and 10% of paper. Ilim Group’s total annual pulp and paper output exceeds 3.2 million tons.

- The Bratsk Evaporation line 8 is the biggest evaporation line in Russia with the capacity of 980 t/h of evaporated water.

- Ilim Group’s confidence on Valmet’s evaporation technology was repeatedly confirmed in 2019, when the company and Valmet signed another contract for a new evaporation plant to Ilim Group’s pulp and board mill being under construction in Ust-Ilimsk.

- Valmet has close to 300 employees in Gothenburg, Sweden focusing on sales, engineering, manufacturing, construction, service and maintenance especially for evaporators, power boilers and recovery boilers.

Related articles