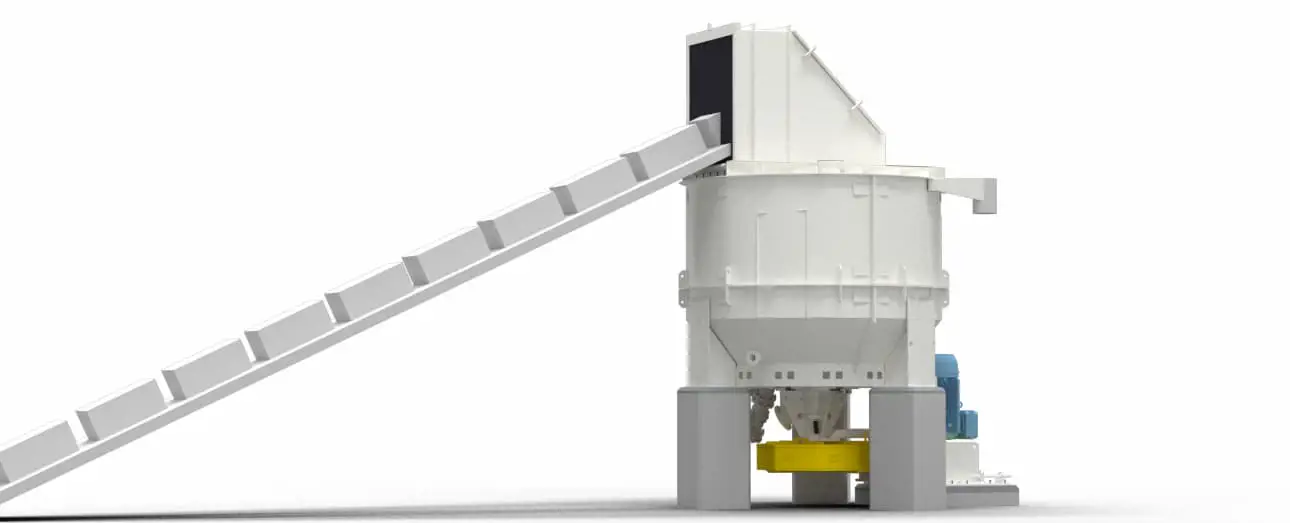

Vertical pulping

Energy saving rotor

Flexibility in batch or continuous operation

High runnability

Proven vertical bale pulping solutions

Valmet Vertical pulper station efficiently achieves critical OCC process targets. The secondary pulping system gives maximal outthrows removal with energy efficiency and high yield in an extremely compact package. Featuring enhanced removal of harmful impurities such as wire, steel and plastic, the Valmet Vertical pulper can significantly maximize pulp quality and production line runnability.