Aqua layering technology

Two-layer sheet with one headbox

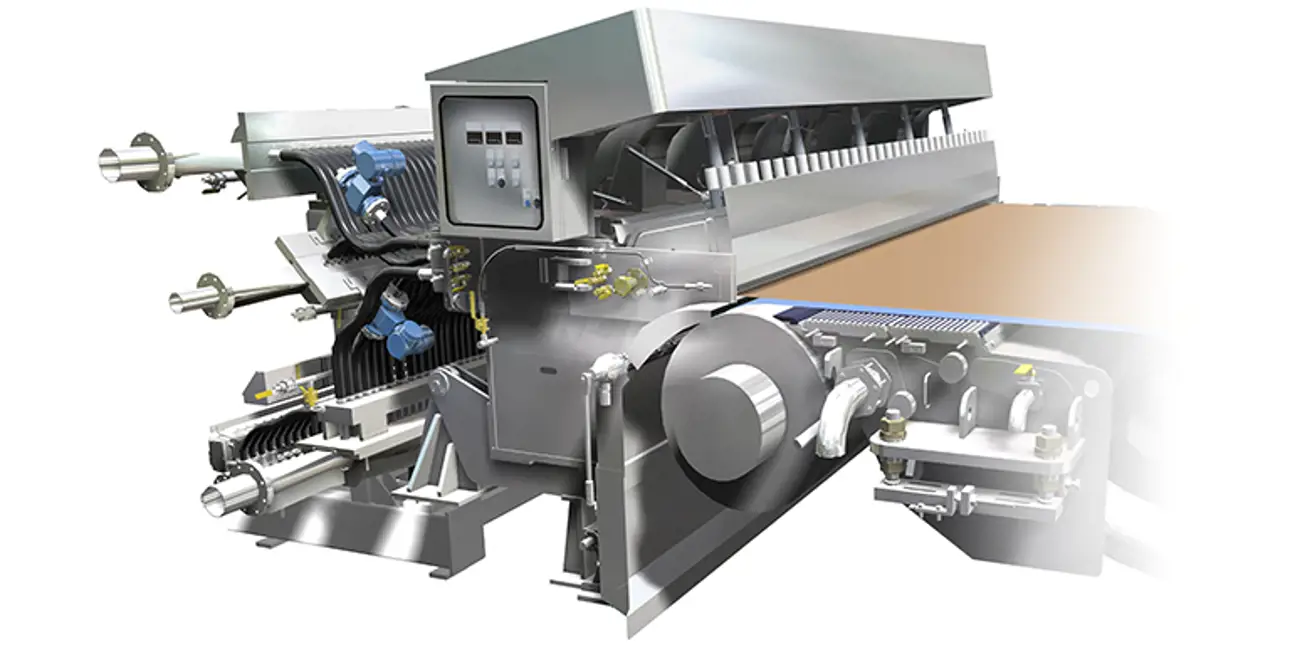

Valmet's OptiFlo headbox with new innovative Aqua layering technology makes it possible to produce a two-layer sheet with very good layer coverage using only one headbox and forming unit. The Aqua layering technology has been developed for the most challenging stratified solutions where layer purity is a key feature. It produces a perfect, disturbance-free, purely layered structure that boosts strength properties.

30% less starch needed

Prevents mixing of stock layers

Enables feeding of functional additives between stock layers

Investment is both cost and energy efficient

How does Aqua layering technology work?

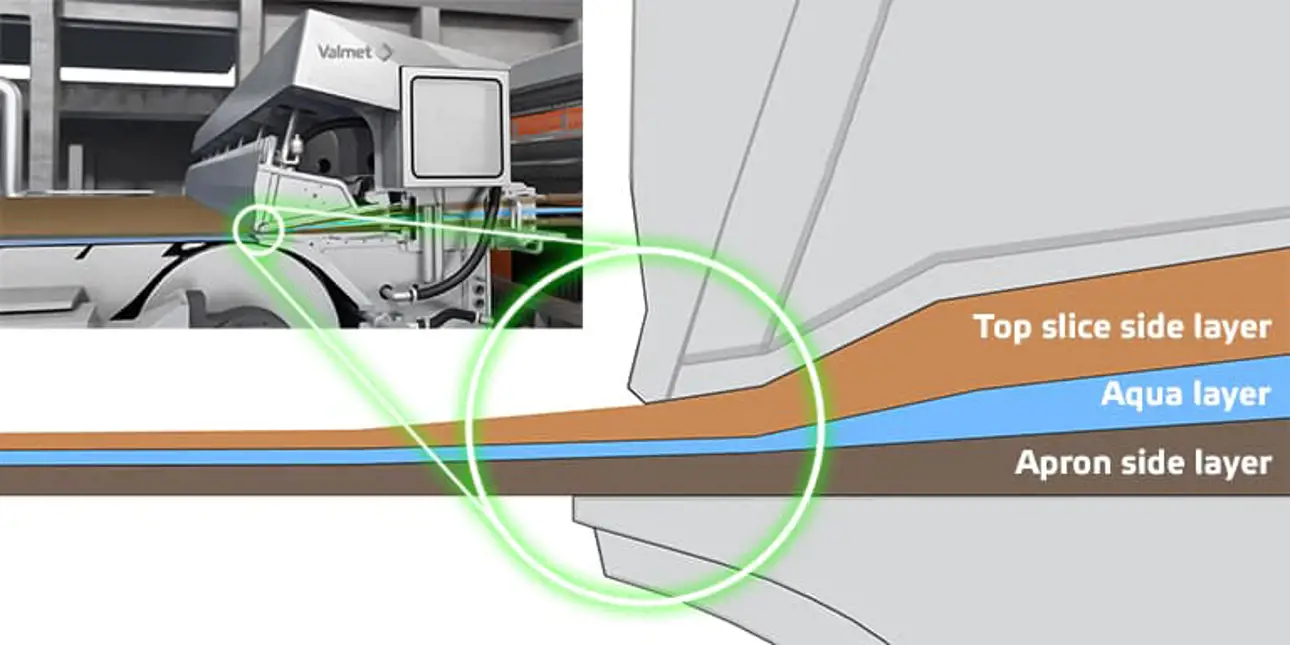

Valmet’s latest headbox innovations – Aqua layering technology – can be used to improve the internal strength of weak middle ply by feeding starch or other additives between the layers. The new Aqua layering technology uses a thin water layer as a headbox wedge to stabilize layers and to form an even film while layers of stratified paper are being joined together. It prevents the mixing of stock layers and also enables the feeding of functional additives between the stock layers.

Principle of the new Aqua layering technology is described in the image, where the thin water layer is used as a headbox wedge to stabilize layers.

Want to talk to our headbox experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsNew resource-saving ideas

This type of layering provides possibilities to adjust the quality and especially strength properties. Cost savings can be achieved, for example, by using different furnish qualities, cheaper raw materials, and functional wet end additives between the layers. Furthermore, as layering is done with one headbox and forming section only, the investment is both cost and energy efficient.

30% less starch needed

At PM1 at Dongil Wolsan mill in South-Korea, the new OptiFlo layering headbox enables feeding starch between the layers. This increases significantly the strength properties of the end product while providing cost savings as 30% less starch is needed for the same strength increase. Read more here.

The Aqua layering technology can be combined with both OptiFlo Layering Fourdrinier and OptiFlo Layering Gap headboxes for optimized end-product quality and cost-efficient production.

How to plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. But where do you start? Download our e-book to learn how to develop a winning rebuild concept, how to minimize rebuild related risks, and how to ensure smooth ramp up to full production.

Download e-bookLooking for headbox related services?

We provide a wide range of professional headbox maintenance and testing services to get the best out of your headbox. These services make it possible to eliminate web streakiness and jet inaccuracy, to lower the need for slice opening adjustments, and to improve dry weight profiles.

Go to headbox servicesInterested in pilot trials?

We offer the opportunity to experiment and develop paper and board products and processes without having to put your own production on hold. This is very cost-efficient compared to expensive tests in your own production. Follow the activities in the trials on site or remotely through live streaming cameras.

Contact our pilot trial expertsExplore our latest board and paper press releases

- Jul 8, 2024Valmet to supply operator training simulator to Graphic Packaging International in Waco, Texas, United States

- Jul 8, 2024Discover Valmet MTC Wizard at Tissue Innovation Days 2024: the latest technology enhances Client benefits in Tissue Folding

- Jul 2, 2024Valmet to supply a high-capacity winder to Wuzhou Special Paper in China

- Jun 26, 2024Valmet to supply both a papermaking line and a paper machine rebuild to a customer in Asia-Pacific

- Jun 25, 2024Valmet to deliver a tissue machine to Andhra Paper in India

- Jun 19, 2024Valmet receives the second order of converting lines to Metsä Tissue in Mariestad, Sweden

- Jun 13, 2024Valmet and Flootech enter partnership to advance water treatment for the board, paper and tissue industry

- May 30, 2024Valmet enters joint venture with Körber to advance the digital offering to the tissue industry

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China