Real-time total solids measurement for wastewater

Valmet Total Solids Measurement - Valmet TS

Control and optimize your total solids using advanced microwave technology with the Valmet Total Solids Measurement (Valmet TS). The most reliable and accurate online measurement for wastewater, the Valmet TS creates new opportunities to save while improving process performance.

Fully control wastewater processes with continuous real-time total solids measurements

Quickly react to process changes and stay on your optimum total solids target

Save time with simple, reliable and completely maintenance-free measurements

Best-in-class accuracy for total solids measurement

With advanced microwave technology and no wearing parts, the Valmet TS is the most accurate and reliable total solids measurement for any wastewater process. Regardless of flow rate or sludge quality variations, the Valmet TS delivers exceptionally precise measurements using rapid data collection and high sample volumes.

The Valmet TS determines total organic and inorganic solids content from 0% to 50%. Because it continuously measures all solids in the process flow, the Valmet TS enables better control for more efficient industrial and municipal wastewater processes. From reducing water content in dry cake, to optimizing polymer dosage a biogas production, running at better pumping capacity and saving on transportation costs, the Valmet TS delivers what you need.

Online, real-time total solids measurement

With the Valmet TS, you can achieve significant savings through optimized mass flow controls, further advancing the environmental benefits of effective wastewater treatment. Enhance wastewater processes by improving overall efficiency and providing crucial data for dewatering optimization.

Valmet TS sensors also have ATEX, IECEx, and UKEX certifications and can be used in Explosion Hazardous Areas.

Industrial sensors for any application

Valmet Bridge control unit

Operation is simple and intuitive thanks to the Valmet Bridge, a touchscreen terminal for Valmet process sensors and analyzers. A graphical interface helps you easily perform tasks from single-point calibration to trend visualizations and running intelligent diagnostics. Featuring the latest Industrial Internet capabilities, the Valmet Bridge is perfect for local operation and remote services.

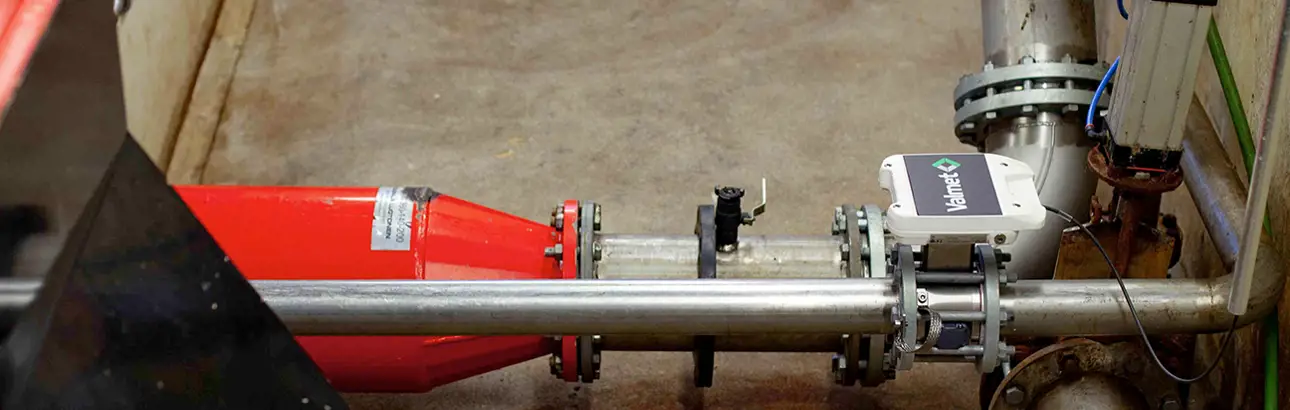

Flow Through sensor

The body of the standard Valmet TS Flow Through sensor replaces a section of the process pipe. Flush-mounted antennas are installed on opposite sides of the sensor body so that the measurement takes place through the process flow. Different linings, such as non-stick and rubber, are available for applications where contamination, grease, or abrasive materials are present. For high pressure rating applications, we also have a high-pressure Flow Through sensor.

Twin Blade sensor

For large process pipes or applications needing higher conductivity limits, the Valmet TS Twin Blade sensors are available. The Twin Blade offers easy, flexible installation and high performance in exceptionally challenging environments.

Solids Measurements For Better Wastewater Control

Download Valmet Wastewater Guide to learn how reliable online solids measurements can be used to optimize and improve plant operations and process.

Download

User Manuals

In our Customer Portal you will be able to find the user manuals you are looking for. The manuals are available in several languages and can be easily downloaded.

Customer Portal