Intelligent control software for sludge dewatering

Valmet Sludge Dewatering Optimizer - Valmet SDO

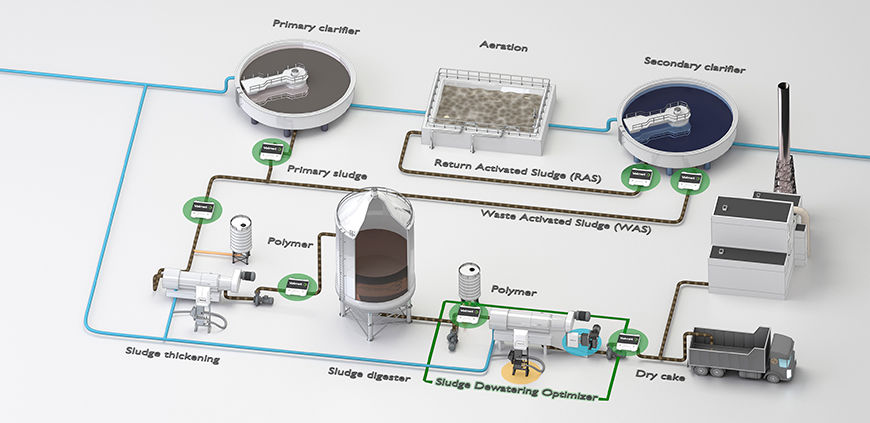

The Valmet Sludge Dewatering Optimizer (Valmet SDO) is an advanced sludge dewatering control application. Used together with Valmet Wastewater Measurements, the Valmet SDO turns accurate measurements into process enhancements for significant savings.

24/7 optimization with less laboratory sampling

Save on polymer usage with continuous feedback on dosing effectiveness

Reduce energy for drying and incineration, along with transportation costs

Complete solution for dewatering process control

Dramatically improve your sludge dewatering processes with Valmet SDO control software. With Valmet SDO, operators can minimize solids in the centrate, while maximizing the solids content of dry cake.

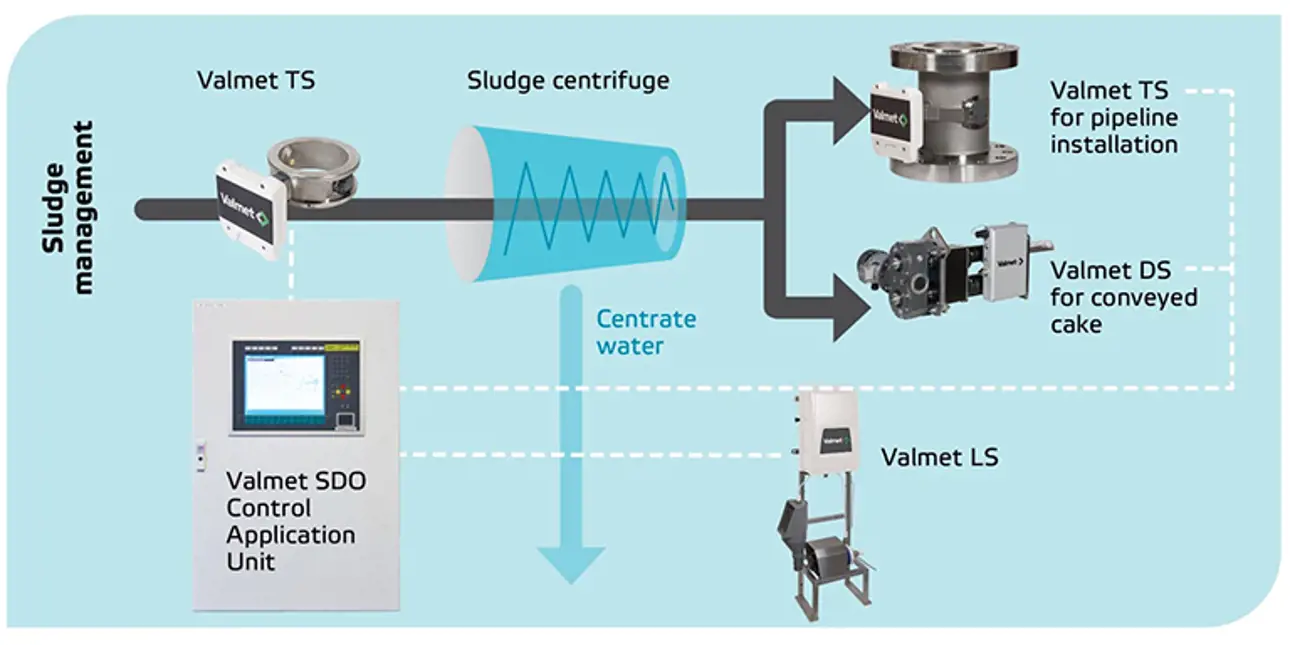

Leveraging the accurate, online measurements from Valmet Total Solids Measurement, Valmet Dry Solids Measurement, and Valmet Low Solids Measurement, the Valmet SDO uses the full range of solids measurements, combined with centrifuge input, to optimize the entire dewatering process.

Optimize all the variables as a single loop

The Valmet SDO utilizes multivariable model predictive control (MPC) to manage polymer dosing and centrifuge torque. In addition, the Valmet SDO stabilizes the sludge mass flow to the centrifuge.

Suspended solids in centrate and total solids in dry cake are controlled in an MPC controller that continuously optimizes polymer dosing and centrifuge torque.

The Valmet SDO control application is a standalone solution with a connection to the plant-wide automation system.

Easy, continuous improvement

For operators, the Valmet SDO is very simple. You just need to select a control mode. The control mode determines how process loop setpoints are defined, which can be manual or through different calculation methods. Once configured, the optimizer work 24/7 to monitor and control dewatering for optimal polymer and energy consumption to achieve your target dry cake total solids amount.

Superior solids measurement solutions for wastewater – test the ROI tool calculator

Solids Measurements For Better Wastewater Control

Download Valmet Wastewater Guide to learn how reliable online solids measurements can be used to optimize and improve plant operations and process.

Download

Downloads |

||

|---|---|---|

| Valmet Sludge Dewatering Optimizer Brochure | Valmet Sludge Dewatering Opimizer Datasheet | View all materials |