Press felts for pulp drying machines

To withstand high process temperatures

Valmet press felts are always tailor-made to the specifications of each individual pulp drying machine and position: furnish, speed, dimensions. With proven world class technology, the press felts are made to withstand high process temperatures and low pH process chemicals which are common in pulp drying processes.

Stable runnability

Excellent dewatering

Good wear resistance

Valmet Press Felts for pulp drying provide:

- resistance against thermal, chemical and mechanical stress

- stable runnability

- excellent dewatering due to high water handling capacity

- good wearing resistance and

- stableness in CMD and controllable width behavior.

Want to discuss felts for pulp drying?

Our felt professionals are here for you. Send us your question and we'll come back to you shortly.

Contact us

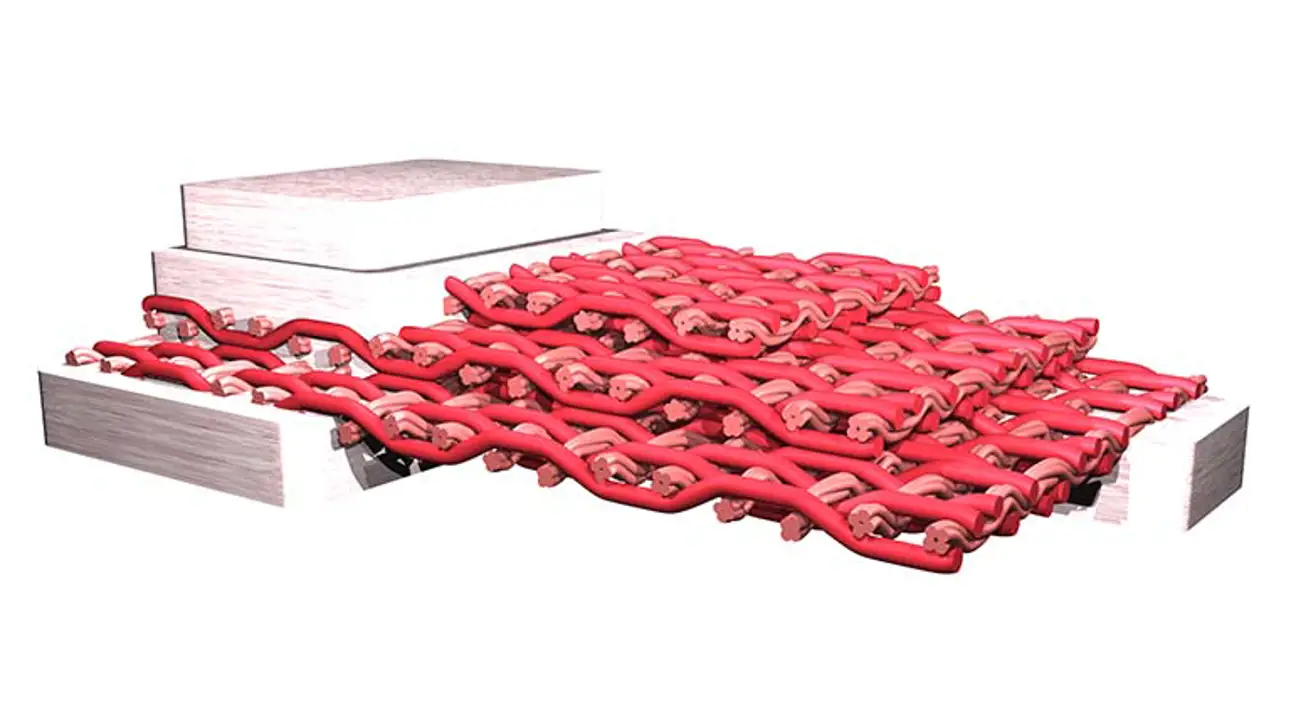

Valmet Press Felt LMR

- Extremely heavy 2+2 monofilament base structure with endless design

- Easily adjustable void volume and openness

- Superior resistance against compaction and filling

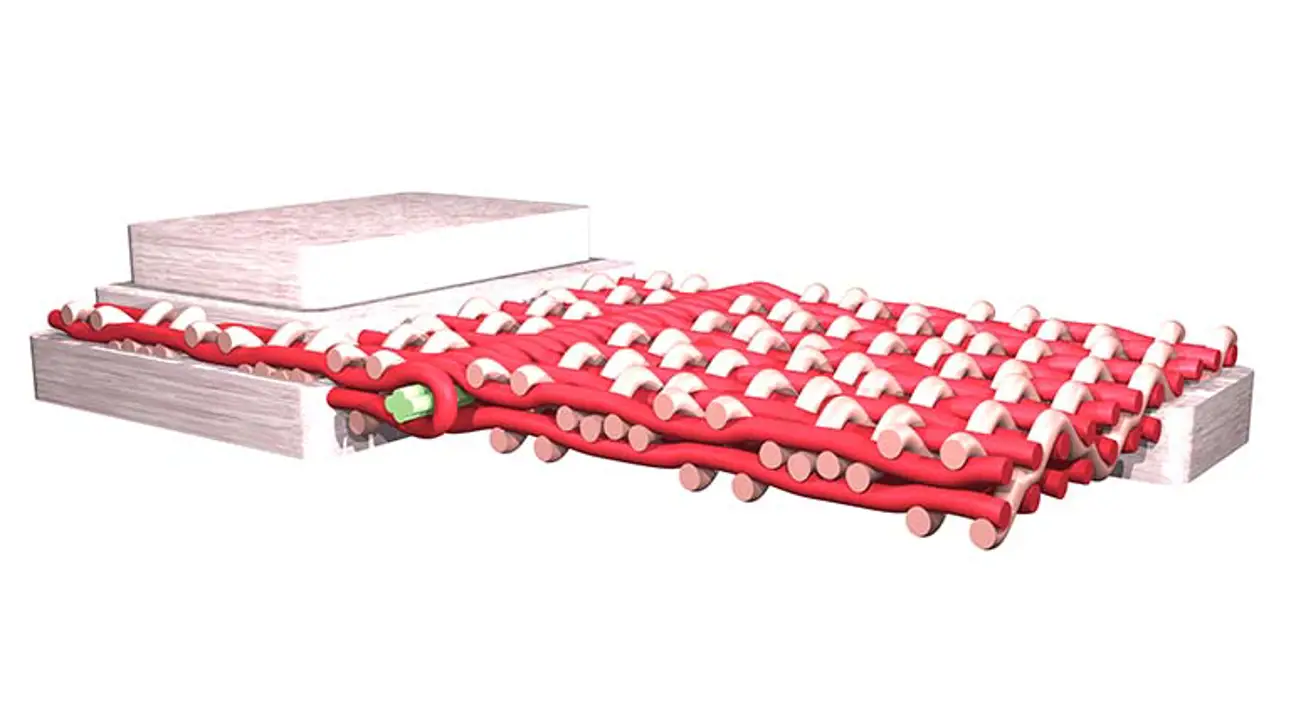

Valmet Press Felt TSM

- Heavy triple layer monofilament base structure with one seam

- Easily adjustable void volume and openness

- Durable structure, good seam area: no seam marking, easy installation

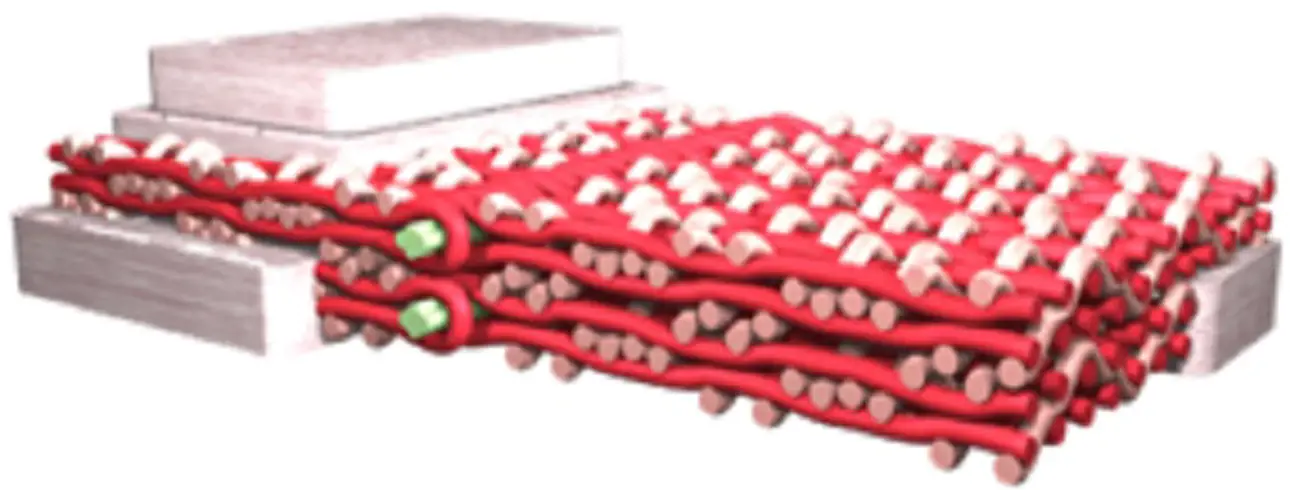

Valmet Press Felt SMS

- Extremely heavy 2+2 laminated monofilament base with two seams

- Double seam design which is durable and easy to install

- Superior resistance against compaction and filling

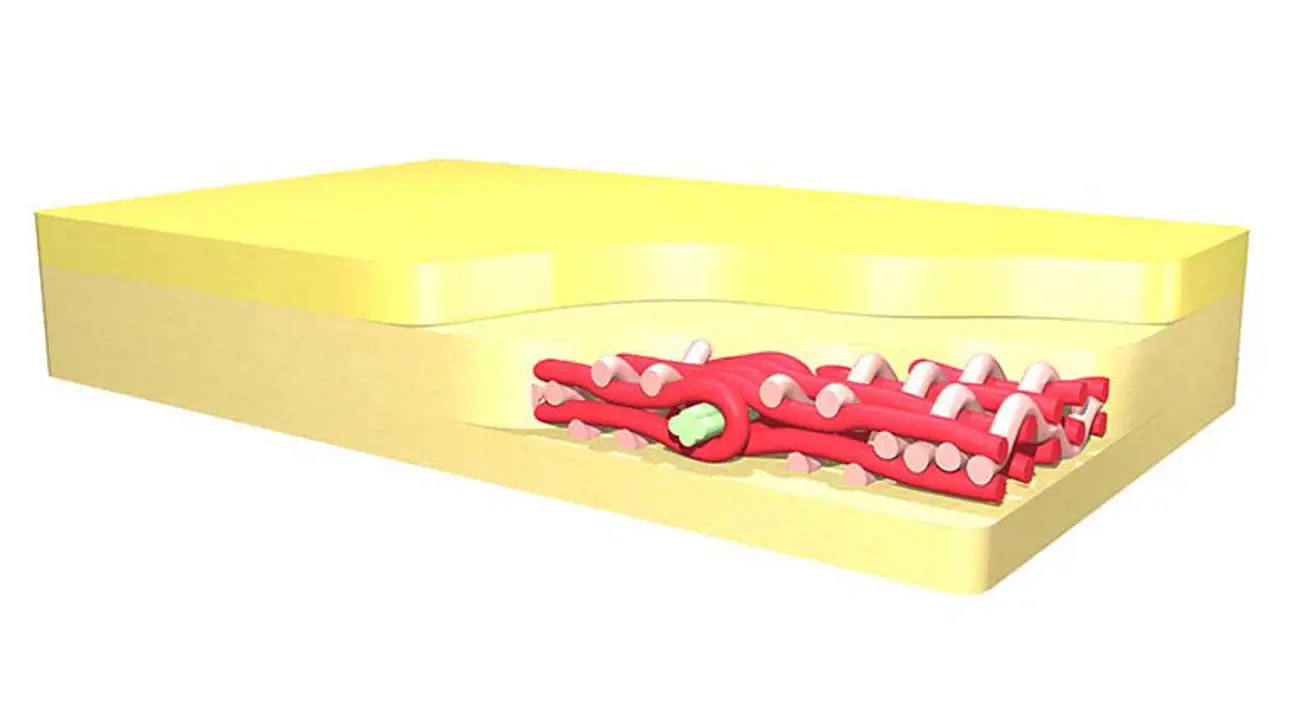

Special Valmet Press Felt SMO design for improved performance and longer lifetime

The manufacturing process of the seamed SMO felt impregnatespolyurethane resin into the regular press felt structure. Impregnation is effective all across the felt structure and can be adjusted according to desired product properites.

The durable treatment lasts throughout the felt lifetime enhancing the runnability, lifetime, dewatering and stability of this special seam felt.

Lifetime

- Chemical resistance

- Wear resistance

- Thermal resistance

Runnability

- Break free running

- No late life problems

- Good machine efficiency

- Controlled sheet release

Dewatering

- Low steam consumption

- Constant dewatering

- Good water handling capacity

Stability

- Stable in CMD

- Less shrinking

- Good edge quality