Filter fabrics for fiberline

Reliability for the pulp bleaching and washing processes

Valmet offers high quality filter fabrics to boost production in the pulp bleaching and washing processes. They are designed to meet the requirements drum filters and double wire presses set for dewatering.

High dry content

Long lifetime

High productivity

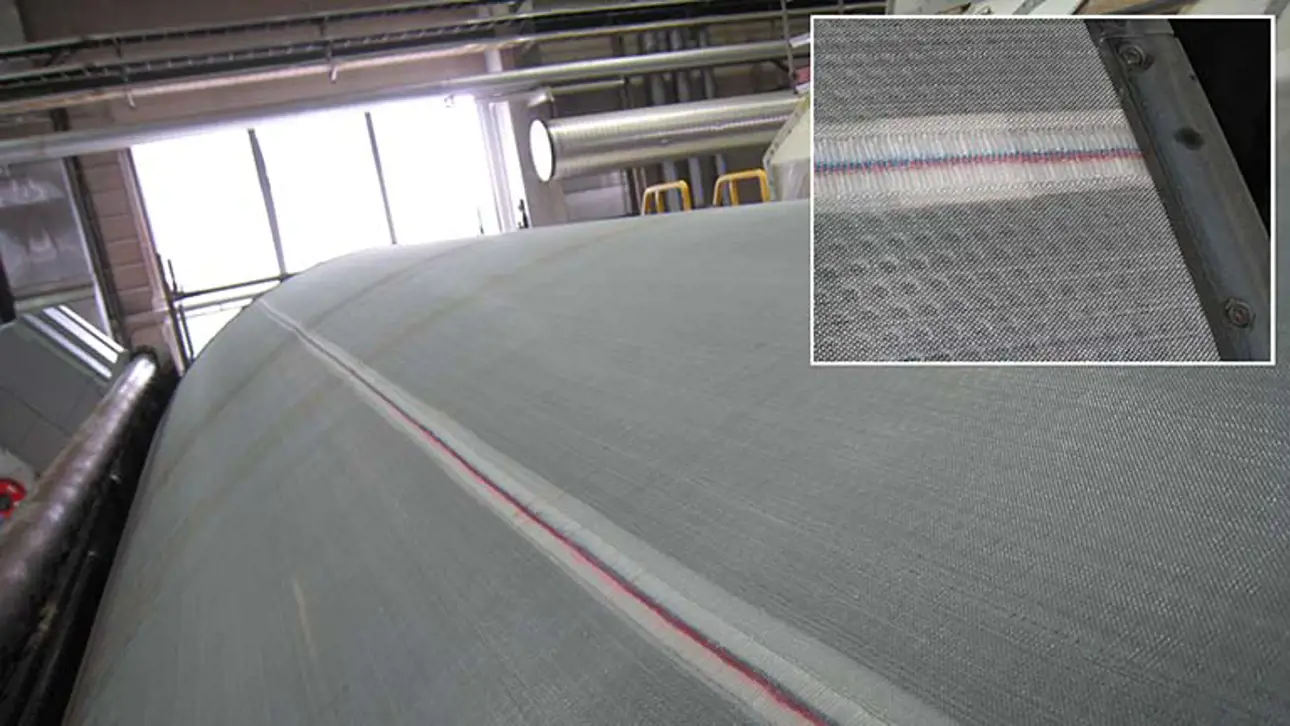

Valmet Shrink Fabrics

In addition to boosting production, Valmet Shrink Fabrics, available in both single and double layer designs, provide many other significant customer benefits:

- Excellent drainage -> high dry content

- Extremely high shrinkage force -> long lifetime

- Unique woven seam structure -> low profile and high strength

- Metal-like structure -> stays clean and runs longer

- No need for welding -> quick installation

- Shrinking starts at low temperatures

Valmet Shrink Fabric SL (single layer) is an excellent choice especially for bleaching and washing drums in the case of blinding challenges and/or moderate fabric washing.

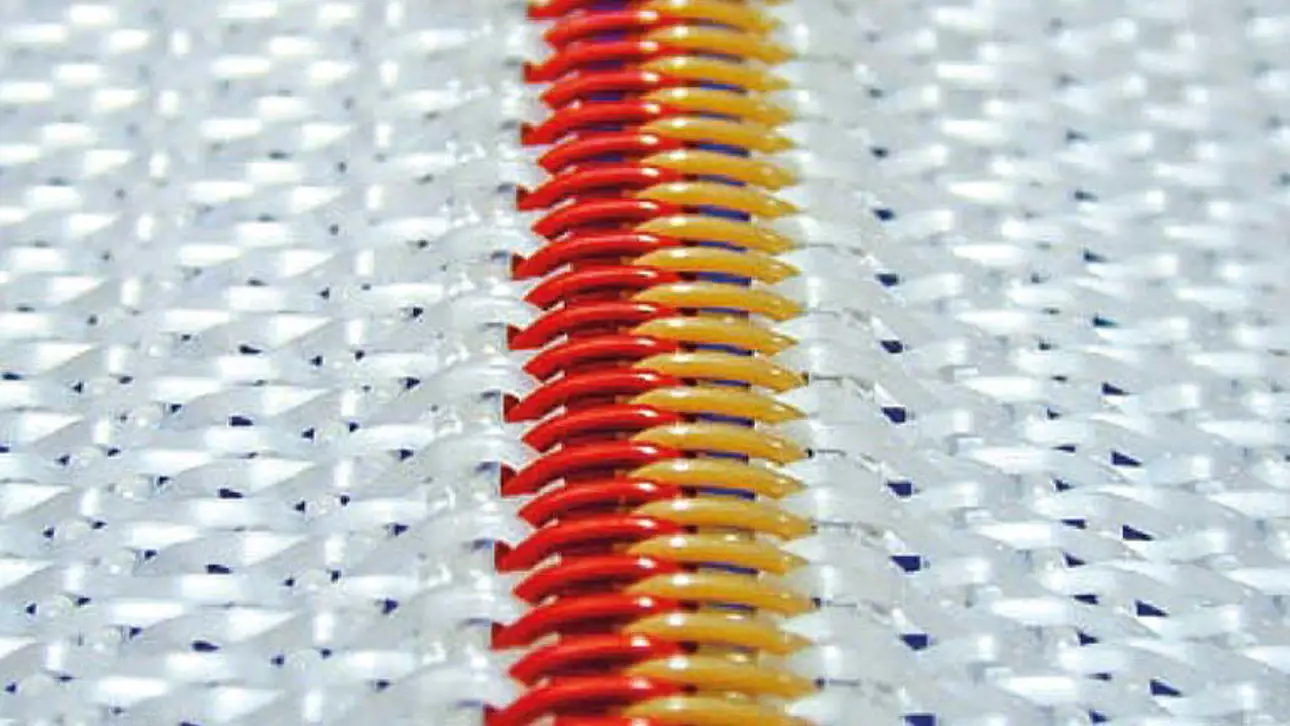

The shrink fabrics feature a patented woven loop seam. As the seam loops are formed during the weaving stage, there is no separate seam structure. The woven seam is very strong and as thin as the fabric itself. This structure contributes to a long lifetime and good mechanical durability.

Valmet’s woven low profile seam is strong and resistant even on drums equipped with pressure rolls.

Valmet Pulp Press Fabric (old name TwinStar)

Our Pulp Press Fabrics are especially known for their stability, abrasion resistance, strong seam and solid edge reinforcement. These features are the backbone to always meet the customer needs of:

- Easy installation - Good running

- High productivity - High dry content

- Clean filtrate - Good sheet release

- No fabric stretch - Low power consumption

- Long lifetime - Minor maintenance

Want to talk to our filtration experts?

Let us hear your concern, and we'll be in touch with you by return.

Contact us