Filter fabrics and services for filtration in mechanical pulping

Enhanced filter capacity

The filtration challenges that the modern wood-processing industry is facing require sophisticated solutions. With state-of-the-art materials, advanced sustainable production methods and thorough quality control, Valmet is committed to helping its customers to find those solutions.

Operational reliability

Long lifetime

Excellent drainage

An absolutely perfect fit for disc filters

All Valmet Disc Filter Bags – regardless of the material – are designed and made to fit perfectly in demanding applications. To ensure absolute precision we use a computer-controlled laser cutter with coded dimensions. In addition to tight and hardwearing stitches, the fabric edges are non-fraying. These fabrics incorporate everything from a perfect fit to the best materials and a long lifetime – everything you need in a disc filter bag to increase filter capacity.

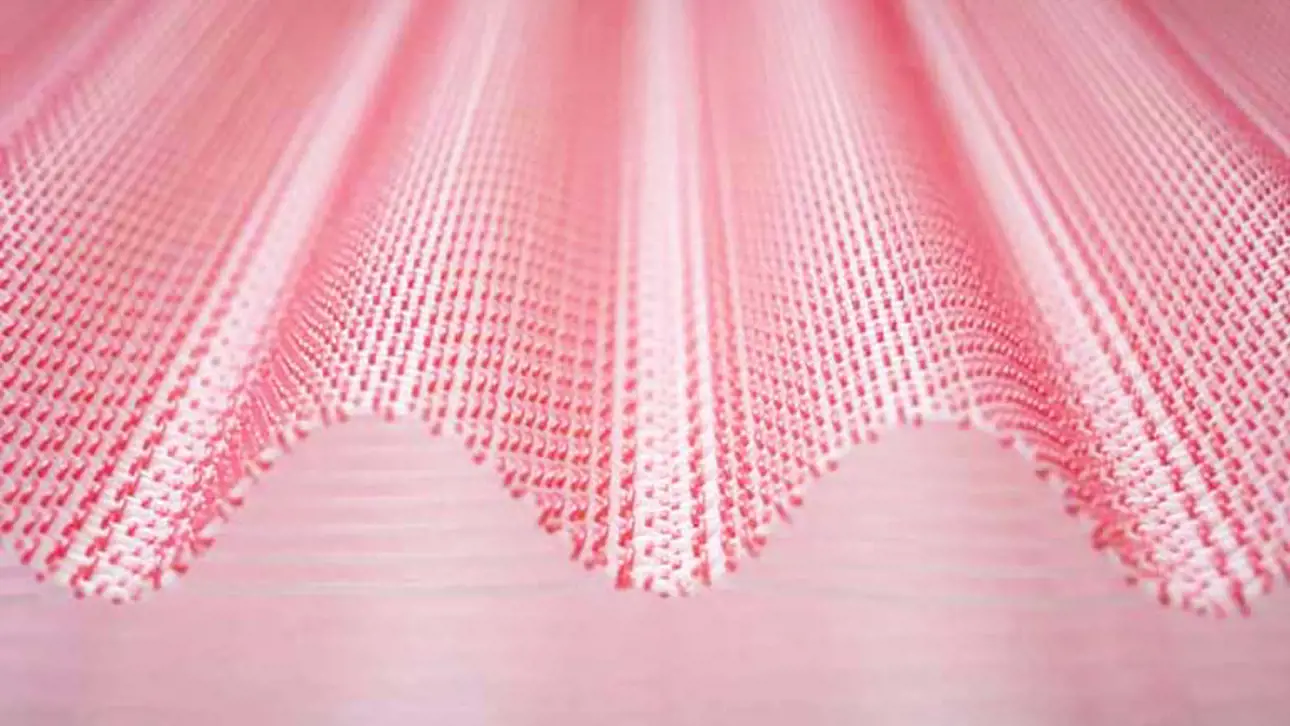

Corrugated Valmet Disc Filter Bag

The bag developed for all kinds of disc filter sectors. The secret lies in its unique fabric corrugation. This solution increases the sector surface area by 29%, enhancing capacity by 10 to 25%. The corrugation also facilitates filter cake removal.

Key benefits

- high capacity

- high pulp discharge consistency

- improved filtrate quality

- cost effective retrofit

- easy maintenance and service

Corrugated Valmet Disc Filter Bag is suitable for new filters and upgrading. It suits all filter sectors on the market. Either a single segment or several segments can be combined with conventional flat-surface segments in a disc filter, depending on the desired capacity increase.

Sectors

We offer several styles of sectors and components with different characteristics to best meet your specific filtration needs.

Dewatering wires for various applications

Valmet Pulp Press Fabric is a product family of high-quality monofilament wires for pulp dewatering. The extensive product range includes various applications such as:

- Dewatering of stocks from hard and softwood, mechanical or chemical pulp, bleached or unbleached

- Dewatering of waste paper

- Municipal sewage and industrial waste water treatment

The fabric features:

- Trouble-free start-up

- Long life: excellent stability, wear-resistant designs, extremely strong edge treatment

- Optimum drainage

- Operational reliability

Shrink fabrics for drum filters

Valmet Shrink Fabric SL is a single-layer shrink fabric designed for drum filters used in chemical and mechanical pulping as well as for recycled fiber. In addition to boosting production, its key benefits are:

- Excellent drainage -> high dry content

- Shrinking starts at low temperatures

- Extremely high shrinkage force -> long lifetime

- Unique woven seam structure -> low profile and high strength

- Metal-like structure -> stays clean and runs longer

- No shrinking in axial direction -> easy to install

- No need for welding -> quick installation

Mill site filtration services in North America

Our over 50 years of experience in the fabrication and installation of filtration products makes us uniquely capable of helping you solve your toughest filtration challenges. From disc filter optimization to leaf testing, our team of experienced technicians can help you get the most of your filtration equipment.

We can assist you during scheduled shutdowns and are available for emergency service as well. Whatever your filtration challenges are, we are ready to help.

Some of the key services we offer include:

- Field service technicians & supervision

- Filter media and wire cloth installation services

- On-site & Off-site disc sector recovery

- Mechanical maintenance services

These are just some of the ways we can help you improve your filtration processes.

Contact us for further information.