Good headbox flow sheet handling and installation prevent damage

Jan 28, 2015

Receiving

Flow sheets are packed for shipment in crates. Keep the shipping crate as flat and level as possible at all times. Do not stand the crate on its edge. Remove any nails that may damage sheets during removal from the crate.

Inspect the sheets immediately upon receipt. Look for damage such as cracks and scratches and report it to the sheet manufacturer and transportation company.

Storage

Store the flow sheets in the original shipping crate. Keep the packing list with the sheets for future reference. Store the sheets in a cool, dry place, preferably indoors. If stored outdoors, provide weather protective cover.

Installation

CAUTION: Use at least two people for flow sheet installation and removal (three or more if the sheet is over 15’ long). All are to wear gloves and use extreme care in handling the sheets to avoid hand cuts and to avoid bending, creasing and otherwise damaging the sheets. Take care not to rest or drag the sheet on any surface that could cause scratches, gouges, etc., such as concrete, asphalt or walk ways. Save the edge protectors as they should be reused when flow sheets are removed.

Some sheet designs use a two-piece hinge assembly. Keep the pieces together and even at all times. For tissue machines, inspect the dovetail of a graphite sheet for impact damage during start-up, shutdown and deceleration of the fan pumps (trip out). This is a problem for stratified headboxes. Equal pressure on both sides of a graphite sheet is essential during start-up, since uneven pressure can cause damage. Gradual pressure change is preferred to avoid excessive forces exerted on the dovetail.

If the sheets are to be laid out of the crate before installation, cover the surface to receive them with clean felt or paper. The surface must be flat and clean. Remove the bolts securing the pondsides to the headbox and open the pondsides. Inspect the seal strips in the slice body end grooves; make sure the strips remain seated in the grooves. Remove all protective materials from the packaged sheets. Lexan sheets may have protective paper covering. Graphite sheets have a plastic edge protector attached to the beveled edge.

The most prevalent cause of damage to graphite sheets is the striking of the edge of the sheet against the side of the headbox during installation. Be sure that the entire edge, not just the dovetail bead, is properly aligned before inserting the sheet into the headbox.

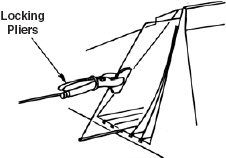

Locking pliers with wide padded jaws may be used. Secure a rope or cable to the pliers and lock pliers onto the sheet. String rope or cable through the sheet region to the other side. Carefully insert the end of the sheet bead into the dovetail groove. Slide the sheet in, keeping it straight and in line with the groove horizontally and vertically. Start with the bottom sheet and repeat the procedure going up.

As each sheet slides farther into the headbox, friction from its weight may make insertion more difficult. Alleviate this problem in one of two ways:

- Apply lubricant to the sheet, or

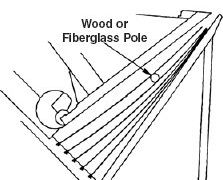

- Use a wood or fiberglass pole under the sheet.

Petroleum jelly is recommended as a lubricant; before using anything else on Lexan sheets, confirm that none of its ingredients are damaging to Lexan.

After the sheets are installed, confirm that each is centered between the pondsides. Make sure each slice body end seal strip is properly seated in its groove. Then close the pondsides, using care to avoid pinching the strips. Reinstall and torque the pondside bolts.

Removal

Before opening the pondsides to remove the sheets, flush the headbox thoroughly with water. After flushing, open the pondsides. Remove the top sheet first and work down. Insert a wood or fiberglass pole under the sheet being removed. The pole will break wet surface tension on the sheet and make removal easier. Keep each sheet straight and in line with the dovetail groove until removed.

Care and Cleaning

Flow sheets require periodic cleaning, based on mill preference, operation experience and sheet material type. Graphite sheets may be cleaned by leaving them in the headbox during boilout. However Lexan (polycarbonate) sheets MUST be removed for cleaning.

Cover the surface to receive the sheets with clean felt or paper. The surface must be flat and clean. Remove the sheets and lay them on a prepared surface. Clean them with a mild soap or detergent and soft bristle brush. Do not direct a pressure jet against the hinge joint.

For more information on headbox flow sheets and their care and handling, contact your Valmet representative.