Valmet Breast Roll Shaker 120 improves sheet properties

Sep 27, 2016

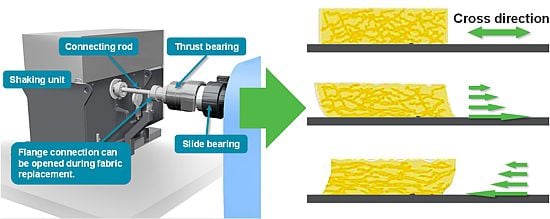

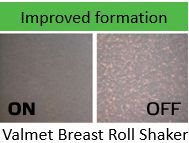

Valmet Breast Roll Shaker 120, Valmet's latest self-balancing breast roll shaker, improves the sheet forming process. It shakes the breast roll cross-directionally and breaks up fiber flocs by creating shear forces on the web. This will result in improved paper and board quality with a stronger sheet, smoother surface for better printability, reduced raw material costs and lower power consumption.

Valmet Breast Roll Shaker 120 shakes the breast roll in the cross direction and breaks flocs by creating shear forces to the web.

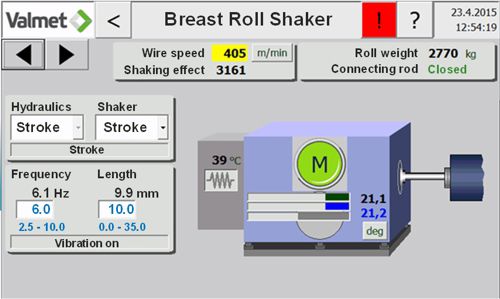

Valmet Breast Roll Shaker is very easy to use: simply set the frequency and stroke length then press the start button on the control panel. It is designed for easy upkeep with few parts needing maintenance. The design is very compact and all equipment is integrated into one unit.

Valmet Breast Roll Shaker is easy to use, enter frequency and stroke and press the start button.

With Valmet Breast Roll Shaker 120 you can achieve the same strength and formation levels with less refining. Raw materials savings stem from minimized starch usage and improved strength properties, even at lower basis weights. And steam consumption in the drying process is reduced. All of these factors result in cost savings for your operation.

For more information on improving your forming section operation, contact your Valmet representative.