One tissue making concept for many possibilities

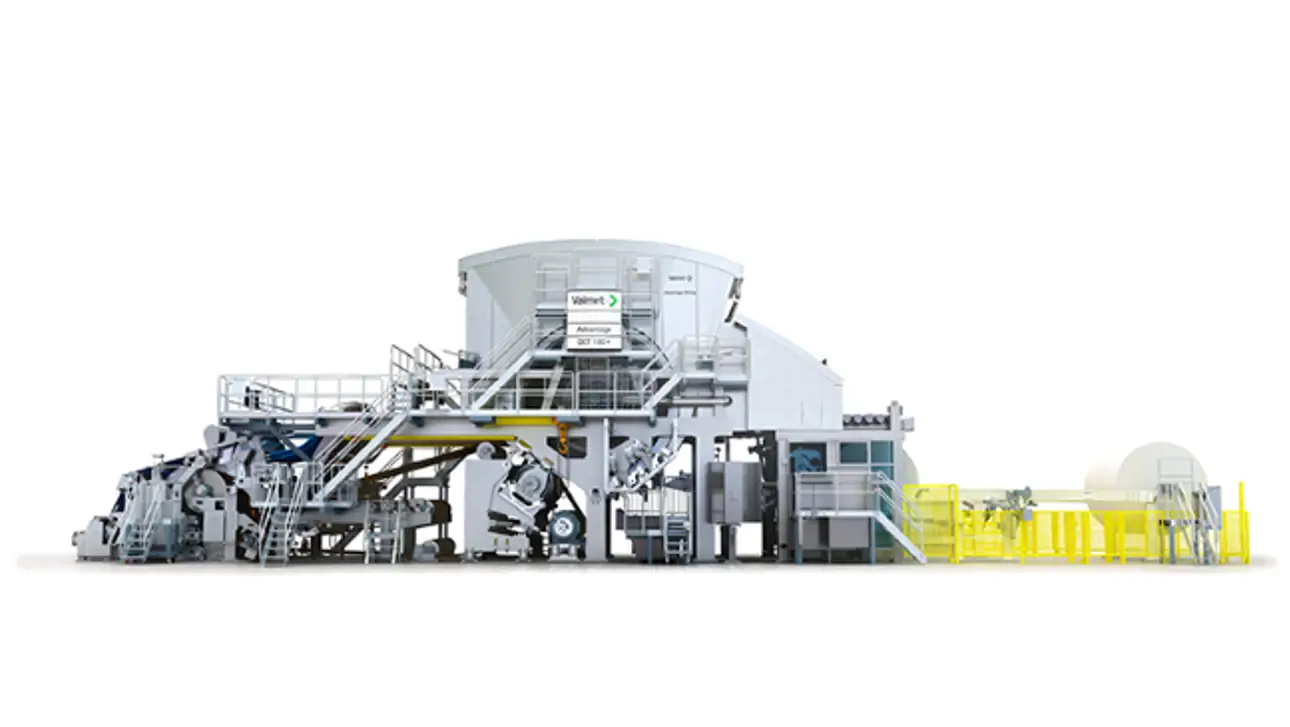

Advantage DCT Technology

The Advantage™ DCT® technology has become a world standard for production of conventional tissue paper. It provides sustainable production of high tissue quality with low energy- and water consumption, high efficiency and reliability at low operational cost. The concept is available in various models and sizes to fulfill each specific production demands.

SUSTAINABILITY

The Advantage DCT technology provides low enery consumption with inventive technology and allows low freshwater consumption.

QUALITY

Offer a flexible product range for all conventional tissue from low to high basis weight with the tools to control caliper and softness. In combination with excellent basis weight and moisture profiles.

COST SAVINGS

With a cost efficient production a low total cost of each ton produced can be achieved. The Advantage DCT technology has a proven steep start up curve.

Conventional high quality tissue production

The Advantage DCT technology concept combines tissue makers’ needs with our extensive technical expertise and application know-how into one state-of-the-art tissue making line. It enables you to produce conventional tissues in cost- and energy-efficient ways by utilizing the Best Available Technology.

The Advantage DCT concept is well established on the market and is known for production of high-quality tissue products of all grades from virgin or recycled pulp at high efficiency.

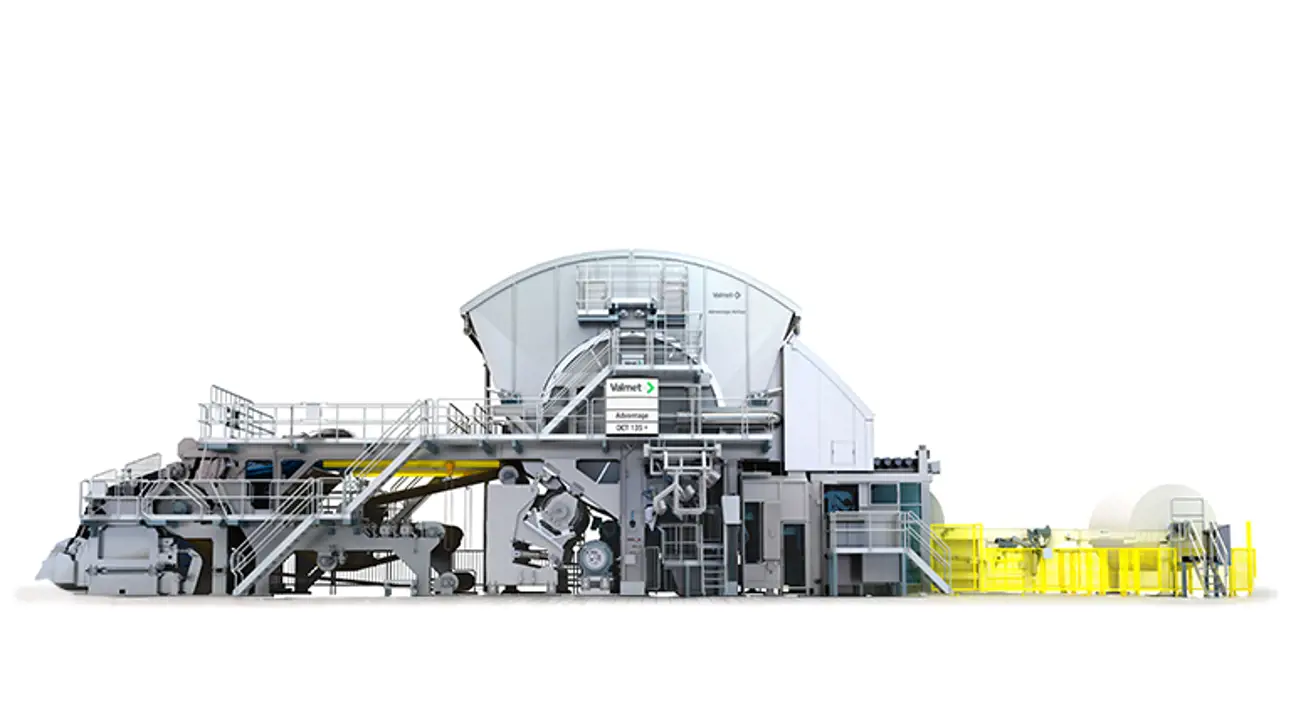

Several family members for extensive production capacity

The Advantage DCT technology concept combines customer needs with our extensive technical experience and expertise into one world-class product. This concept together with several versions of production lines enables Valmet to offer cost- and energy efficient solutions covering a wide range of tissue types and production capacities.

Compare the different models below to find the most suitable option for your production needs.

| Advantage DCT 100+ | Advantage DCT 100HS | Advantage DCT 100 TS | |

| Paper sheet width: | 2850 mm (112 inch) | 2850 mm (112 inch) | 2850 mm (112 inch) |

| Design speed: | 1800 m/min | 2000 m/min | 2200 m/min |

| Yankee size: | 16 feet | 16 feet | 18 feet |

| Headbox: | OptiFlo II TIS 1830 | OptiFlo II TIS 2200 | OptiFlo II TIS 2200 |

| Capacity: | 106 tonnes/day | 118 tonnes/day | 130 tonnes/day |

| Advantage DCT 135+ | Advantage DCT 135 HS | Advantage DCT 135 TS | |

| Paper sheet width: | 3800 mm (149.5 inch) | 3800 mm (149.5 inch) | 3800 mm (149.5 inch) |

| Design speed: | 1800 m/min | 2000 m/min | 2200 m/min |

| Yankee size: | 16 feet | 16 feet | 16/18 feet |

| Headbox: | OptiFlo II TIS 1830 | OptiFlo II TIS 2200 | OptiFlo II TIS 2200 |

| Capacity: | 142 tonnes/day | 150 tonnes/day | 173 tonnes/day |

| Advantage DCT 200+ | Advantage DCT 200 HS | Advantage DCT 200 TS | Advantage DCT 300 | |

| Paper sheet width: | 5640 mm (222 inch) | 5640 mm (222 inch) | 5640 mm (222 inch) | 8020 mm (316 inch) |

| Design speed: | 1800 m/min | 2000 m/min | 2200 m/min | 2200 m/min |

| Yankee size: | 18 feet | 18 feet | 18 feet | 18 feet |

| Headbox: | OptiFlo II TIS 1830 | OptiFlo II TIS 2200 | OptiFlo II TIS 2200 | OptiFlo II TIS 2200 |

| Capacity: | 210 tonnes/day | 222 tonnes/day | 257 tonnes/day | 333 tonnes/day |

A full-scale Technology Center for pilot testing

At Valmet Technology Center we offer the opportunity to experiment and develop tissue products and processes without having to put your own production on hold. Follow the activities in the trials on site or remotely through live streaming cameras.

Book your pilot trial

A dialogue with data to improve the performance

Valmet Industrial Internet offering covers an extensive range of solutions and applications for tissue mills in order to optimize the full scope of the production. The data driven applications and services support you throughout all the phases of the tissue machine’s lifecycle.

As a start we normally explore the potential of utilizing data through a data discovery process. Then we can evaluate what applications within production capacity, quality, energy efficiency and reliability, are beneficial for your operation. Further, our expertise is easily available for you through the Valmet Performance Centers (VPC). Our specialists have a deep understanding of machinery, processes and automation and with connections and tools, we can offer the needed remote support and guidance without delay from our 8 centers around the worlds.

Explore our VII guidebooks

What is the Industrial Internet? What do you need to know about it? And how can you make it work for you? We have prepared guidebooks to open up the most important elements of the Industrial Internet and to explain why and how data can benefit your business.

Get your guide