Steel or Casted Yankee – that’s the question

Oct 29, 2019

Selecting the right Yankee merits careful consideration. After all we are dealing with the heart of your tissue machine here. Steel and casted Yankee dryers both have their benefits, in different areas, depending on your type of production. This is a guide to what is important to consider.

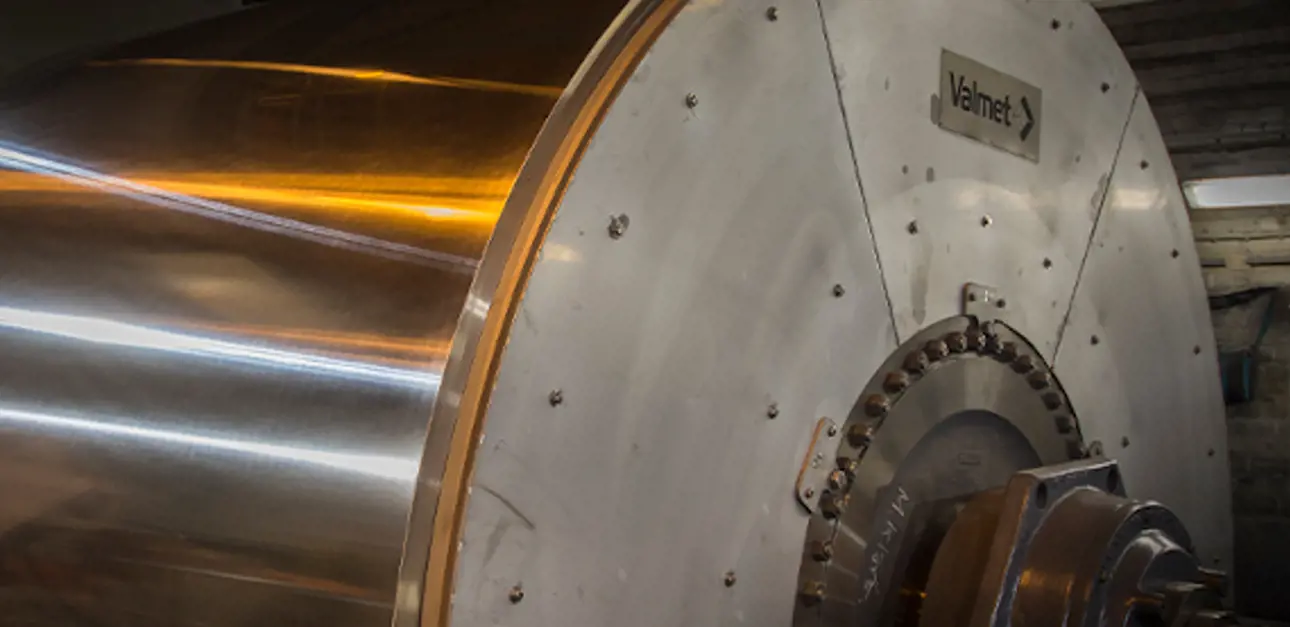

Well over 100 years since it was invented, the Yankee dryer is still at the heart of tissue mills around the world. But while the essence of the Yankee remains the same, today’s dryers differ greatly from those of a century ago. Technical developments have improved safety, performance and availability.

For a long time, Yankee dryers were supplied only by a few manufacturers with access to their own specialized foundries. With the development of more reliable, full face thermal spray coatings in the 1990s, steel Yankee dryers also became a viable alternative for the manufacturing of creped tissue papers.

Consequently, nowadays when selecting a Yankee dryer, one significant decision that most mills will face is the choice between steel and cast iron. Here it is important to consider factors such as capacity, efficiency, process compatibility, operational cost and risk minimization.

No single solution can offer the best fit for all mills, and the specific circumstances and needs of your production process, tissue products and market.

Working with a supplier that has ample experience with and a complete range of both varieties can therefore also play a critical role in making sure you get the best solution for your production.

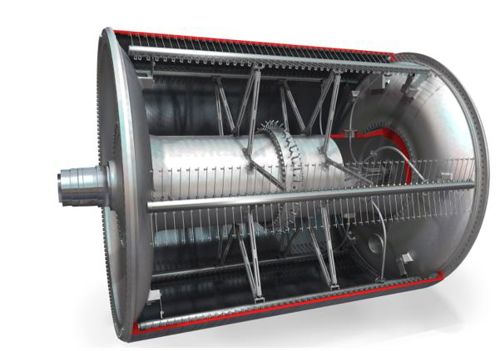

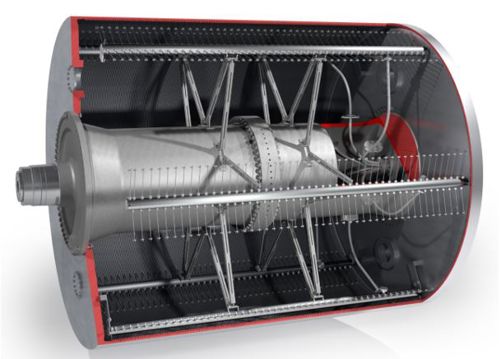

|

|

| ”Valmet cast Iron Yankee dryers originates from 1891. They are typically suitable and proven for all processes but in particular for high nip loads up to 150 kN/m, TAD and hybrid tissue making processes” | "The first steel Yankee dryers were launched in early 2000’s. They are typically suitable and proven for most conventional tissue making processes with nip loads up to 120 kN/m” |

Strong arguments for steel

There is a wide range of characteristics to consider when choosing a Yankee dryer, from drying performance and efficiency to safety and durability. In certain areas, steel can offer advantages over cast iron.

Most notably, steel is a stronger material. This means that the dryer design can have a thinner, more thermally efficient shell with greater drying capacity. If your process so admits, you can utilize the added capacity, in turn, to shift drying from the hood, creating potential for reduced energy consumption. Steel is also a ductile material and generally better suited for pressure vessels.

The case for cast

But this is only half the story. While steel can provide the best choice for some tissue producers, cast iron also presents a number of clear advantages.

Cast iron can be especially beneficial when it comes to characteristics that deal with durability. The material’s free graphite ensures a high level of resistance to corrosion and erosion and, although steel is a stronger material, cast iron benefits from good fatigue – press load - resistance.

Further, cast iron provides a good papermaking surface as is and does not need to be metallized as does the softer steel shell.

When thinking long-term, consider that cast iron has demonstrated reliability in Yankee dryers throughout their century-plus history. There is far less data available on the long-term performance of newer steel Yankee technology.

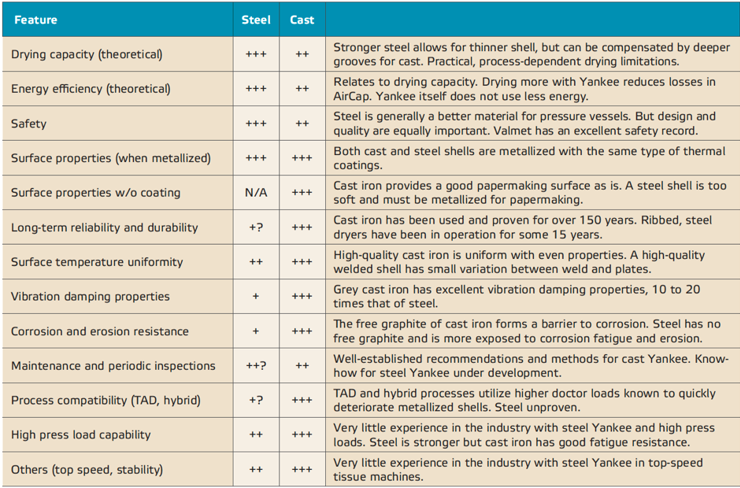

Side-by-side comparison

Still not sure? Take a look at this table for an overview of how steel and cast iron Yankees compare when it comes to different properties and characteristics. Which factor is most important in your production?

Selecting the right Yankee

Selecting the right Yankee merits careful consideration. After all we are dealing with the heart of the tissue machine here.

And as far as giving our advice, our current conclusion is that steel Yankee dryers are suitable and proven for most conventional tissue making processes and in particular for maximizing Yankee drying rates where possible.

Cast iron Yankee dryers are suitable and well proven for all processes but in particular for high nip load Yankees for use with extended nip presses and in processes that utilizes higher than conventional doctor loads like hybrid and thru-air drying processes.

|

“Steel Yankee dryers needs to be metalized before use. Recently Valmet launched Infinikote II, the first Chrome free metalizing in the market” |

|

“The surface of a Yankee needs to be absolutely perfect to create the best paper sheet. Also the rest of the dryer is thoroughly tested due to the fact that it is a pressure vessel.” |

|

|

“To ensure optimized performance or remove chatter marks, the Yankee can be re-grinded at site.” |

Article publisher: Magnus Högman

More info about Steel and casted Yankee dryers

Category: Guidance

Industry level: Introductory

Est. read time: 3 minutes

Summary: This article compares steel and cast iron materials for Yankee dryers and explains

what tissue mills should think about when choosing between the two.