Field Services for white liquor plant

Fast on-call equipment services, shutdown management, support and recommendations on-site or remotely

On-site and remote field services in the recausticizing area with high-level standards for safety and work quality for pulp mill processes and equipment. We offer field services such as inspections, audits, studies, troubleshooting for green liquor clarifiers, slakers, causticizers, white liquor clarifiers, lime kilns etc.

Optimized chemical quality

Heat and mass balance

Optimized yield

Increased availability

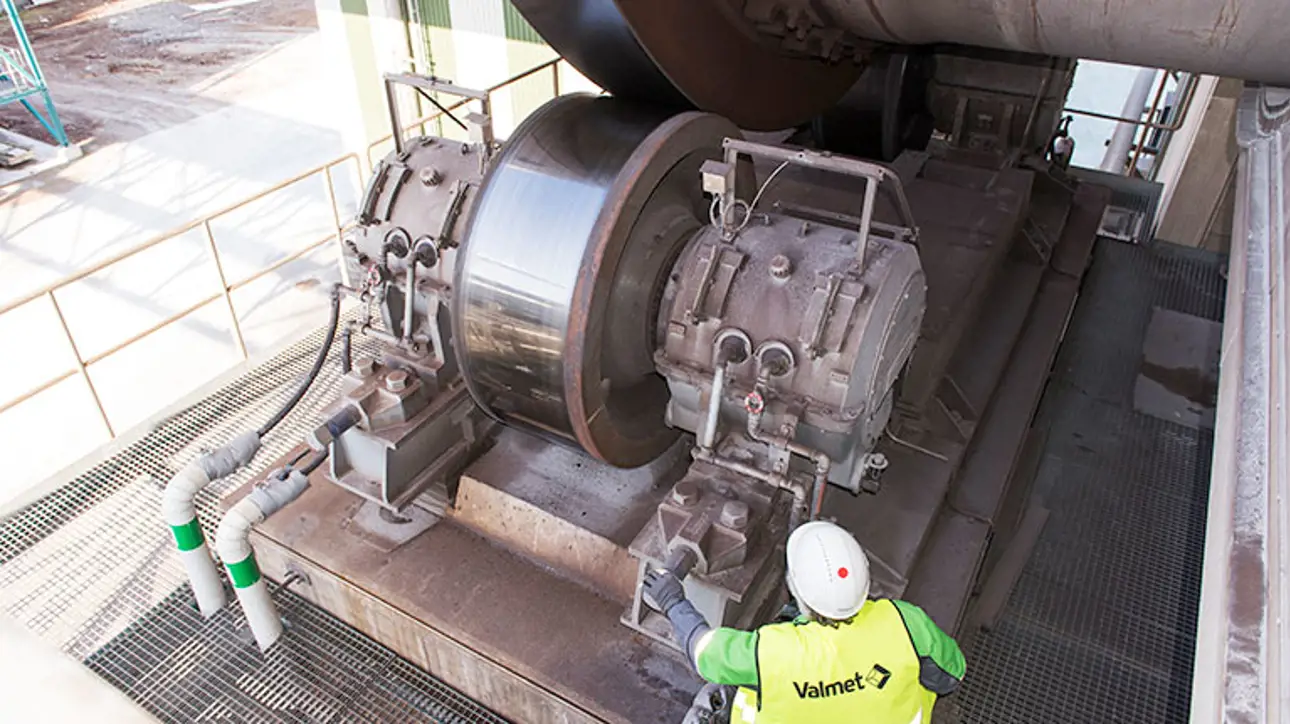

Valmet Recausticizing Mechanical Services

Valmet delivers service solutions and takes responsibility for the entire annual downtime in the recausticizing area. With the help of our service expertise knowledge of process and equipment, performance will remain optimized.

Read more about the benefits of our recausticizing mechanical services.

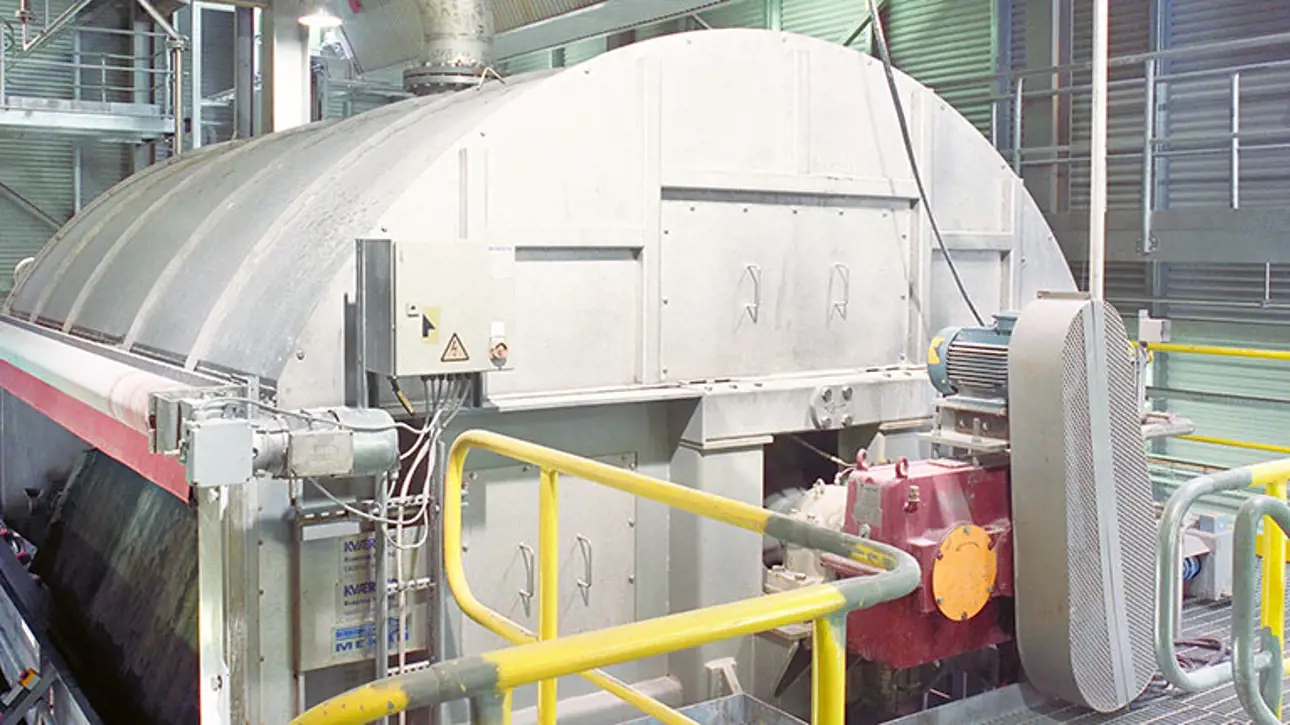

Valmet Pressure Disc Filter Service

Pressure disc filter service will secure the production and runnability of the machine, lower maintenance cost & you will get a good know how about the equipment performance.

- Increases availability

- Reduces maintenance cost

- Process improvements

- Increases lifetime of the machine & equipment

Learn more how can we help you wtih our pressure disc filter service.

Valmet Recausticizing Mechanical Audit

Recausticizing audits aim to secure operation/status of customers installed base equipment in their recausticizing plant. To inspect, detect & document all finding for preventive work or future rebuilds. By choosing Valmet Recausticizing Mechanical Audit you can achieve the following benefits:

- Optimized spare parts needs

- Process improvements

- Increased availability

- Lower maintenance cost

- Valmet´s knowledge of all equipment & process

- How to improve/maximize life length of equipment

Questions about equipment maintenance or support for equipment or process performance development?

Whether it’s a single process survey, equipment maintenance, shutdown management or full maintenance, don’t hesitate to contact your closest Valmet Service Center for guidance.

Contact us

Valmet Lime Mud Filter Service

Lime Mud filter service will secure the production and runnability of the machine, lower maintenance cost & you will get a good know how about the equipment performance. Achieve the following results with the help of Valmet Lime Mud Filter Service:

- Improved run ability

- Lower maintenance cost

- Process improvements

- Increased availability

Valmet Lime Kiln Audit

Valmet Lime Kiln Audit service combine process and burner performance with the mechanical condition of the equipment. Valmet combines all kiln specific functions in the same inspection, such as process, mechanical, and automation. With Valmet Lime Kiln Audit we can help you with:

- HSE evaluation of the current lime kiln work environment

- Overall assessment of kiln performance Recommendations for optimization

- Heat and mass balance

- Mechanical measurements and verifications

- Critical actions

- Improvement actions

- Long-term development actions

- Spare parts planning and maintenance

keyboard_arrow_leftBack

{{currentHeading}}

{{productForm.Name}} {{"("+productForm.Size+")"}}