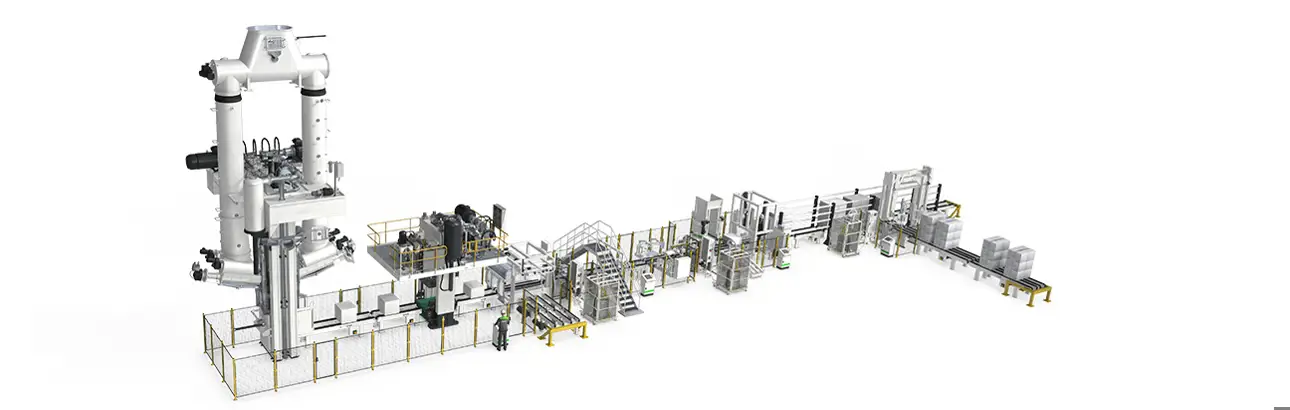

Field services for baling line

Onsite and remote trouble-shooting, inspections and audits to provide recommendations for improvements and spare parts

We strive to be your field service and maintenance partner in terms of preventive maintenance, spare parts needs and improvement opportunities for your baling lines. Bale Handling system consists of equipment with many moving parts and some with large complex hydraulic systems.

Increase the availability of your production

Improve overall equipment efficiency (OEE)

Ensure line safety

Bale handling system consists of equipment with many moving parts and some with large complex hydraulic systems. As an OEM supplier with experience from our globally installed base, we can assist with optimization, troubleshooting and maintenance to increase the mill's profitability. Collaborating with machine and line life cycle plans and preventive maintenance work will increase the availability of your production, your overall equipment efficiency (OEE) and capacity.

Our expertise on baling automation and processes is avilable to ensure you are running with the latest versions of machine software, line safety and optimized machine functionality.

Benefits for your bailing line

• A professional audit from Valmet will ensure optimal use of the installed equipment and maximize efficiency while minimizing service costs

• The audit report provides a detailed picture of needed investments for planning future growth and optimization

• Through greater knowledge of machinery status, life cycle costs are kept to a minimum.

Baling line audits to plans the future of your baling line

A professional audit from Valmet will ensure optimal use of the installed equipment and maximize efficiency while minimizing service costs. Our baling specialists will do a analysis of the future plans for the production line and a long term investment plan is created to reach the customers goals.

Read more about Valmet Baling Line Audit.

Mechanical inspection to find malfunctioning parts

Our baling specialists will do a inspection of the mechanical components of the machine to find any malfunctioning parts or excessive wear.

Spare parts recommendation

A plan for spare part handling is made based on the mechanical inspection. Determining what parts to keep in stock and intervals for change.

A study of the current machine to reach future goals

Our baling specialists will do a analysis of the future plans for the production line and a long term investment plan is created to reach the customers goals.

A study of the current machine program is done to evaluate:

• Program cycle waste time

• Program optimization possibilities

• Possible maintenance reducing program changes

Questions about equipment maintenance or support for equipment or process performance development?

Whether it’s a single process survey, equipment maintenance, shutdown management or full maintenance, don’t hesitate to contact your closest Valmet Service Center for guidance.

Contact us

Greater knowledge of machinery status by slab press audits

Valmet offers slab press audits to ensure maximum utilization of the installed machinery. Whether new or old, a Valmet machine should always run flawlessly.

Read more about Valmet Slab Press Audit.

Performance testing to evaluate current bale qualities and get recomendations

To evaluate the current machine performance, a maximum capacity test is performed. During the test, measurements are taken to find the current bottleneck in the system and to evaluate current bale qualities to recommend changes to meet customer specifications.

Ensure correctly mounted seals by bale press cylinder seal replacements

The purpose of using Valmet experts and Valmet Bale press PR15 cylinder seal replacements in performing Seal replacement service is to ensure that the seals are correctly mounted and to secure the alignment of the main cylinder when re-assembled.

Download more information about cylinder seal replacements:

Download Field Services Mechanical Pulping Handbook

Do you need equipment maintenance or support for equipment or process performance development? This handbook provides guidance on best practices to maintain your operation in good condition. It includes service interval recommendations to help prevent unexpected failures at your mechanical pulp mill.

Download

Download Field Services Chemical Pulping Handbook

Do you need equipment maintenance or support for equipment or process performance development? This handbook gives you guidance in best practices for keeping your operation in good condition at your chemical pulp mill.

Downloadkeyboard_arrow_leftBack

{{currentHeading}}

{{productForm.Name}} {{"("+productForm.Size+")"}}