Chloride and Potassium removal with Valmet Ash Treatment

Valmet's ash treatment systems help keel levels of Chloride and Potassium at low levels in pulp mills all over the world. Several mills have returned to Valmet for upgrades as the mills have increased production.

Chloride and Potassium

Chloride and Potassium enter the mill with incoming raw material and water. Since the chemicals change the properties of the ash in the recovery boiler, it's very important to remove them from the mill's liquor cycle.

If the ash in the recovery boiler becomes sticky, it can be difficult to remove by sootblowing. This can lead to buildup that plugs the recovery boiler and makes it necessary to stop it for water washing. And both Chloride and Potassium can accelerate corrosion in the boiler's superheaters.

Valmet solutions

An ash treatment system from Valmet removes Chloride and Potassium from the liquor cycle. This can lead to increased uptime and production.

Valmet offers three solutions that bring different benefits. The solutions are well proven and several mills have returned to Valmet to increase the capacity of their original installation as the mill has expanded.

The working principle

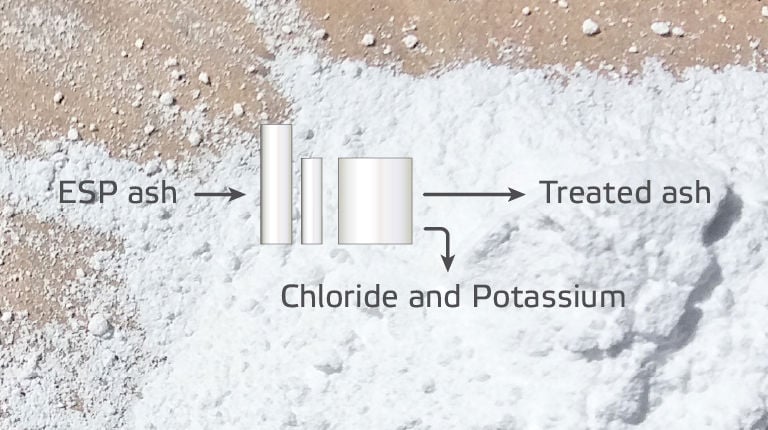

Valmet's technology uses water to separate Chloride and Potassium from the other chemicals in electrostatic precipitator (ESP) ash.

When ESP ash is mixed with water, Chloride and Potassium dissolve, while the pulping chemicals remain as solids. The solids can be separated from the liquid and returned to the mill. The liquidcontains the unwanted chemicals and is led to wastewater treatment.

Performance

Valmet ash crystallizers offer up to 96% removal of Chloride. This is very close to the theoretical maximum limit of a crystallizer process, and it’s therefore a good indicator of the high performance of Valmet’s design.

Cooking chemicals are valuable and should be kept in the mill. The high recovery rate is therefore the second good feature of Valmet’s ash treatment systems.

Rates of removal and recovery are controlled by chemistry, which means that the content of the ESP ash affects both removal and recovery. As the content can vary over time, Valmet’s ash treatment systems are designed to be able to work well even when variations occur. This ensures high performance in the long run.

Our expertise is at your service

Our focus is to bring your performance forward utilizing our extensive experience and in-depth knowledge of pulp process technology. Get in touch with our experts through your local Valmet office, or the link below.

Contact us