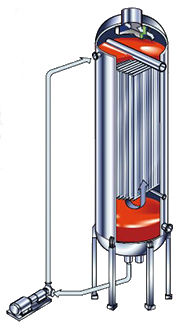

Tubel Evaporators

Valmet’s well-proven Tubel design has been shown to provide greater availability in high dry solids or scaling applications.

High dry solids without scaling problems

In a Tubel evaporator, a falling film of liquor is evaporated on the outside of tubes heated by steam or vapor.

The open design eliminates the risk of plugging. And the large distance between the tubes minimizes the risk of bridging.

On-line washing is easy, thanks to the convex shape of the tube surface. Off-line washing, with hydroblasting, is normally never needed in kraft liquor applications.

Mechanically reliable

The heating surface in Tubel Evaporators are manufactured in our own workshops with proven, automated manufacturing methods.

Tubes are mechanically reliable and give the heating surface superior strength and a longer service life. Valmet’s Tubel Evaporators are known for their outstanding reliability.

Higher capacity at very high dry solids

High pressure/high temperature steam can easily be used in a Tubel Evaporator. This can increase the evaporation capacity, or reduce the viscosity of the liquor at very high dry solids contents.

Compact concentrator

When space is limited, a Tubel Concentrator is normally designed with one shell divided into two or more sections. For best operating characteristics, steam and liquor circuits in the sections are controlled separately.

Tubel – the ideal solution

Tubel is the ideal solution for applications where scaling problems may arise and is therefore very suitable for concentrators. Moreover, the mechanical reliability of old plate-type units can be improved by replacing their heating surfaces with Tubel elements.

CMPC Celulose Riograndense, Guaíba, Brazil

6-effect Valmet Evaporation Plant, capacity 1740 tons/h, 80 % DS. Tubel concentrator for highest availability and easy washing.

Stora Enso Skoghall, Sweden

Complete new falling film evaporation train with excellent 9+-effect steam economy, integrated CTMP liquor evaporation and efficient condensate handling. Capacity: 580 tons of black liquor and 173 tons of CTMP liquor per hour, 80% DS product.

Our Technologies

Our expertise is at your service

Valmet’s focus is to bring your performance forward. We work to ensure that you get the most from your evaporation plant. To get in touch with us, use the link below, or get in touch with your local Valmet office.

Contact us