Valmet MVR Evaporators

MVR (Mechanical Vapor Recompression) is a good way to improve the mill’s overall steam economy and condensate segregation. Valmet’s MVR evaporators are optimized for minimum fan power, which lowers the operating cost.

MVR improves overall steam economy

Low operating cost through Valmet's design with minimized fan power

MVR: black liquor pre-evaporation, sulfite spent liquors, BCTMP and mill effluents.

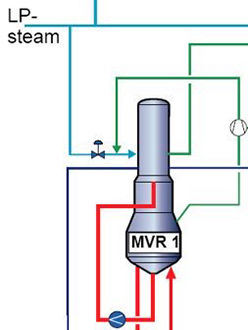

In an MVR Evaporator, a fan or turbine drives the evaporation. The fan creates energy for the evaporation by increasing the steam pressure.

Valmet’s MVR evaporators are designed for low fan power. This lowers the cost of energy and thereby the operating cost for the MVR evaporators.

MVR Evaporators are especially suitable for concentrating liquors with a low boiling point rise. MVR is often used for black liquor pre-evaporation, evaporation of sulfite spent liquor and evaporation of mill effluents. BCTMP mills can often benefit from installing MVR evaporators.

MVR evaporators at Cenibra

The two MVR pre-evaporators Valmet delivered to Cenibra (Celulose Nipo-Brasileira) in Brazil significantly improved the overall steam economy and condensate segregation at the mill. Capacity: 235 tons/h.

Our Technologies

Our expertise is at your service

Valmet’s focus is to bring your performance forward. We work to ensure that you get the most from your evaporation plant. To get in touch with us, use the link below, or get in touch with your local Valmet office.

Contact us