High-performance condensate handling

Valmet Evaporation plants can be designed to produce condensates that can be completely reused in the mill. This greatly reduces the mill’s consumption of fresh water.

Optimized solutions

Each new Valmet Evaporation Plant is tailored to meet the mill’s needs, and the condensate segregation systems are usually optimized. The removal efficiencies can be above 97%.

Internal condensate treatment

In an evaporation plant with internal condensate treatment (ICT), condensates are recycled and treated in Valmet Tube Evaporators.

Intermediate B-condensates are converted into clean A-condensates that can be re-used in the mill.

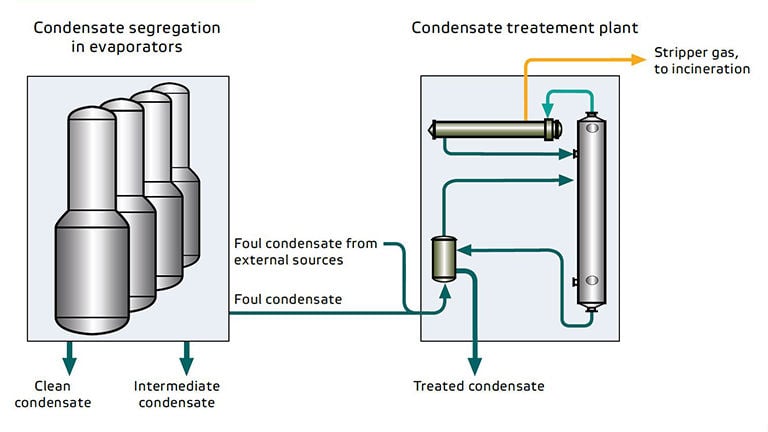

Independent or integrated operation

Valmet’s condensate treatment systems are designed for optimal cleaning of contaminated condensates from the cooking and evaporation plants.

It can be operated independently or be integrated with the evaporation train for improved overall heat economy.

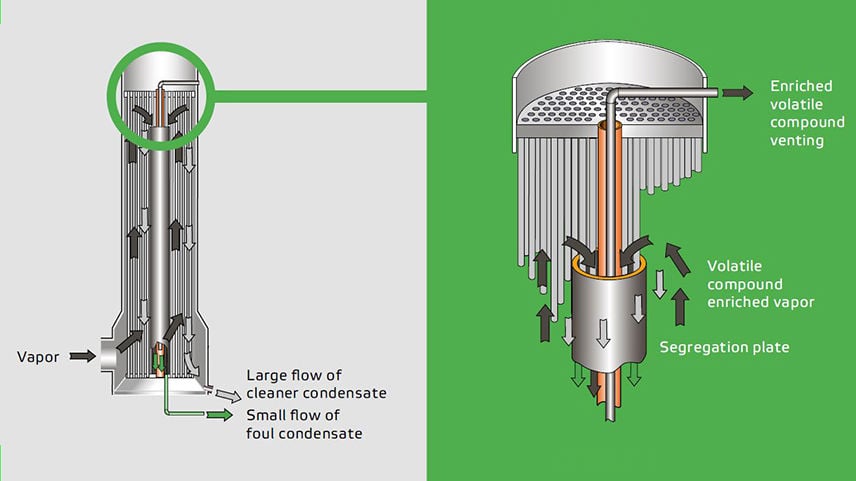

Internal vapor segregation

Evaporators heated with contaminated vapor are equipped with our well-proven design for internal vapor segregation.

With this design, 80–90% of the malodorous contaminants in the vapor may be segregated into a small foul condensate fraction. This small stream of foul condensate is normally cleaned in the condensate treatment plant.

Larger streams of clean and intermediate condensates are usually reused as wash and/or dilution water in the fiberline and recausticizing plant. This substantially reduces consumption of fresh water and bleaching chemicals.

Our Technologies

We bring your performance forward

Valmet is the world’s leading supplier of methanol and condensate treatment plants, with more than 200 successful installations in operation worldwide. Our focus is to bring your performance forward and we work to ensure that you get the most from your evaporation plant. To get in touch with us, contact your local Valmet office, or use the link below.

Contact us