Managing pulp quality in stock preparation requires fiber measurements

Jan 12, 2023

PT Surya Pamenang located in the outskirts of Kediri, East Java recently invested in a Valmet Fiber Furnish Analyzer (Valmet MAP Q) to further improve its coated folding boxboard sold in both domestic and export markets. This is an Indonesian first, since it is the first Valmet MAP Q installed in the country. The analyzer included Freeness and Fiber Imaging modules plus 7 samplers installed in the mill’s stock preparation department. Earlier, stock preparation was mostly controlled only by a few daily Freeness measurements taken as a hand sample and the role of fiber properties was a new concept for the mill’s management of product quality. The Valmet MAP Q analyzer incorporates new fiber imaging technology which provides micro-scale details from fiber dimensional properties to shives and their size categories. Monitoring incoming pulp quality and subsequent fiber development during refining provides the opportunity for better control of stock preparation.

Monitoring quality

PT Surya Pamenang purchases well selected pulps which after cleaning and deflaking are refined for properties to suit final product requirements. The board consists of three plies in which the outer plies (bottom and top) require different pulp formulation from the one used in the middle ply. To better evaluate the pulps the mill buys from its suppliers, three samplers for the analyzer are located in the separate inlets of the refining lines for LBKP, NBKP and BCTMP pulps. The other four are located at outlet of the refining lines (bottom, mid, and top layer) and broke line. The seven sampling points are automatically measured in sequence with each measurement taking approximately five minutes.

The user interfaces supplied with the analyzer have proven to be very useful tools for process management. Operators often have analyzer screens in control rooms, from which the operation of the process can be monitored based on measurements.

Remote support

Installation locations were checked and suggested by Valmet during the early phase of the project with installation work carried out by the mill. Valmet’s local expert handled commissioning and hands-on training for production, laboratory and instrument personnel supported remotely from Finland because of Covid restrictions. Likewise, remote access to the analyzer facilitated expert fine tuning together with the ability to install the latest software versions as needed. The measurements are now in daily use by operators and have reduced the need for manual sample analysis by the laboratory team.

"The strong presence of local expertise and the remote support of experts was a really effective way to carry out the commissioning. In practice, the project progressed as the team worked together regardless of place and time", according to Ismo Joensuu, Manager, Board & Paper Analyzers.

A Total Commitment to Quality

PT Surya Pamenang, company motto is "A Total Commitment to Quality", clearly reflected in its never-ending efforts to improve product quality and now well supported by Valmet MAP Q. Better monitoring of incoming pulp quality and control of refining levels are being further improved with the analyzer’s built-in Valmet Data Modeler to predict pulp strength properties from the measurements. After startup, training in use of the modeler was performed remotely from Finland and now mill personnel are now really interested in developing their process by looking for cause and effect relationships as well as challenge suppliers to improve the pulp qualities they deliver.

From left: Mr. Dony Sugiharto, Production Head, Mr. Elisafan Sjalom ,QC Head, he is also in charge of process R&D from Stock Preparation to Paper Machine, and Mr. Hendy, Paper Machine DCS Operator

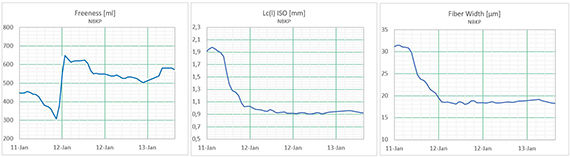

The importance of fiber measurement

A dramatic “cause and effect” was discovered within months of start-up when checking the analyzer performance. A large deviation in measured Freeness observed, but without fiber measurement the reason would have been unresolved. Shorter than normal fibers could be seen from the long fiber sample line. On investigation a defective valve was discovered causing short fiber to flow into the long fiber line. Without the MAP Q fiber measurements, this would not have been resolved. After this incident, no one questioned the importance of fiber measurement.

Especially production management is very satisfied with the new tool, they are now able to see the pulp quality from the supplier and the pulp quality before the machine using Valmet MAP Q.

“Pulp quality management has reached a new dimension with fiber measurements. With the help of fiber measurements, it is possible to monitor not only Freeness measurement, but also its quality.”

Lifelong healthy value provider - PMA Service agreement for Valmet MAP Q

At the end of the delivery project, the plant entered a preventive maintenance contract that includes regular and advance semi-annual maintenance visits by local and remote experts. The contract includes also emergency service visits and remote checks, if needed.

“The service agreement is very important to keep analyzer availability and accuracy always on top level. Also, it ensures fast response action whenever there is any need for checking analyzer performance”, says Muchtar Arifin, Senior Service Specialist.

Related articles