Residual measurement for optimized chemical addition, pulp quality and bleaching equipment protection

Valmet Residual Measurement – Valmet Polarox6

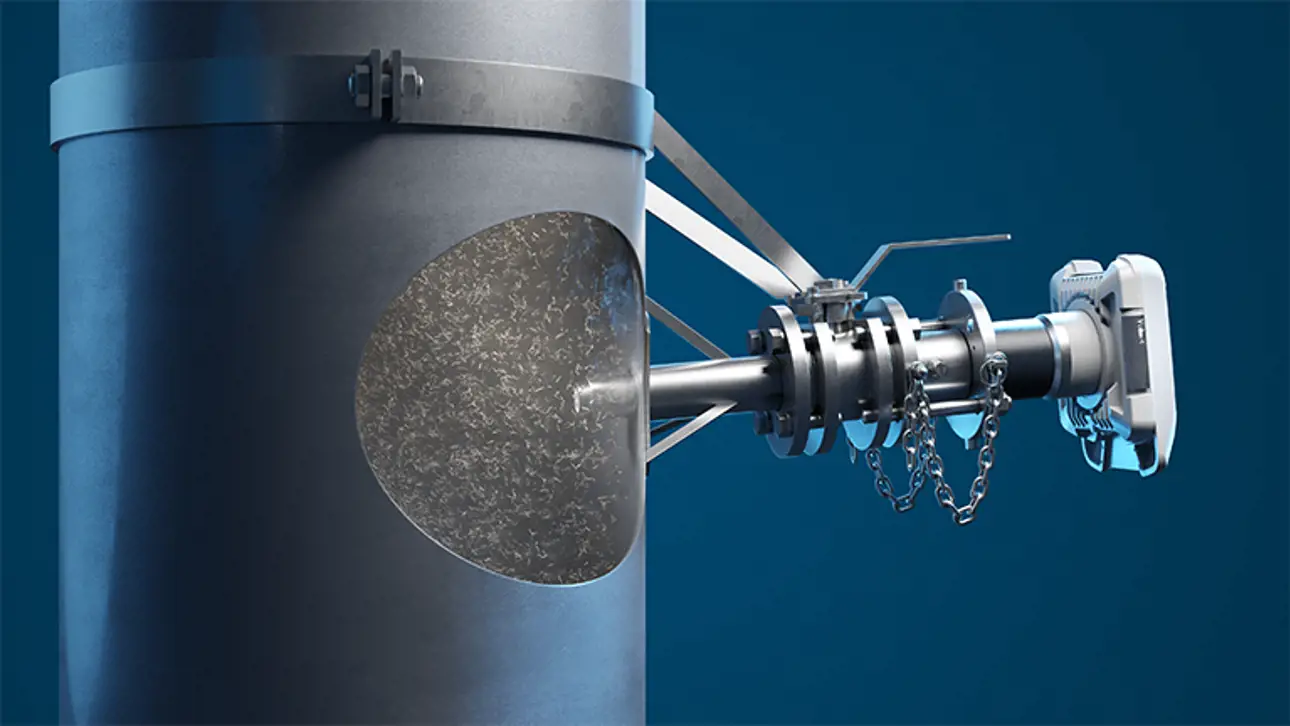

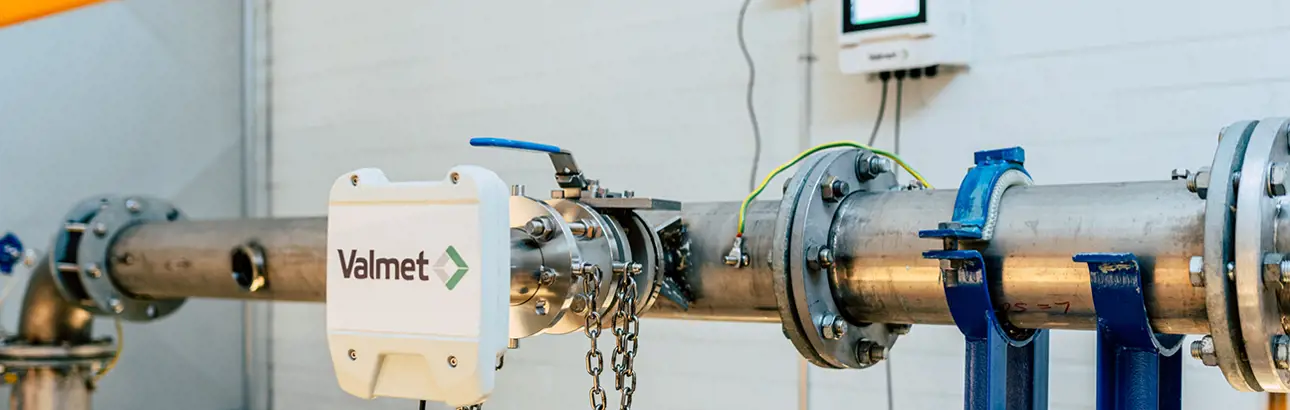

The Valmet Residual Measurement (Polarox6) is the sixth generation of Valmet’s inline measurements for pulp bleaching. Based on decades of experience in residual measurement, this robust and proven sensor features the latest automation technology.

Direct bleaching chemical savings

Better quality of fibers by precise chemical dosing

Bleaching equipment protection and safer operation due to no excess residual chemical

High pulp quality and bleaching equipment protection

When you need to optimize chemical addition, ensure high pulp quality and protect your bleaching equipment, Valmet Polarox6 is the right solution for the job. Installed before the bleaching tower, the sensor provides immediate information about bleachability, based on pre-chemical consumption (feed-forward). This allows for a fast response to adjust chemical addition controls. When placed after the bleaching tower, it measures the residual bleaching chemical and gives accurate feedback for dosage control and process equipment protection.

Enhanced residual measurement for precise dosing

The Valmet Polarox6 brings decades of Kajaani™ measurements experience and proven residual measurement performance to the world of advanced automation controls. The latest Polarox generation features a modern interface for easy desktop or mobile device access. A wide range of supported communication standards provide full compatibility with other Valmet products and control systems.

The robust yet sensitive electrochemical measurement uses an automatic cleaning sequence and intelligent diagnostics to ensure stability and reliability. Our versatile residual measurements are suitable for control applications such as kraft pulp bleaching and residual neutralization, mechanical pulp bleaching, and DIP/RCF bleaching.

Peroxide Residual Measurement

The Valmet Peroxide Residual Measurement (Polarox5 FP) measures both total residual peroxide and residual OOH– ions, giving you deeper insight into actual process conditions.

With these new insights, you can avoid peroxide over charging or caustic overdosing. Based on the enhanced measurement capacity of Valmet Polarox5 FP, new P-stage control options are available to achieve the best final brightness target with optimal caustic and peroxide charges.

Filtrate Residual Measurement

In chlorine dioxide stages, it is important to measure the total chlorine, including chlorite. The Valmet Filtrate Residual Measurement (Polarox5 F) can measure chlorite shortly after chemical addition. This ensures that sufficient bleaching chemical is available for the whole reaction time. Get the brightness you need without compromising safety and environmental conditions or using excessive amounts of chemicals.

Continuous pH measurement provides important information for the process management as the reactions of chlorine dioxide and chlorite are pH dependent. The integrated optional pH measurement in Valmet Polarox5 F allows tighter pH control for optimal process conditions.

Downloads |

||

|---|---|---|

| Valmet Residual Measurement Datasheet | Valmet Peroxide Residual Measurement Datasheet | Valmet Filtrate Residual Measurement Datasheet |

Related optimization solutions