LNG processing and intelligent valves for a demanding service

Jul 7, 2022

The demand for natural gas is increasing globally due to its clean-burning characteristics, which is especially true for producing electricity and many industries are looking into LNG as an alternative, cleaner source of energy. For LNG producers the difference between running safe, profitable plants often comes down to choosing flow control partners with the experience and knowledge to get the job done right.

LNG is simply natural gas in its liquid form. Natural gas is converted into LNG by cooling it to -160°C (-260° F), at which point it becomes a liquid. This process reduces its volume by a factor of more than 600, which allows natural gas to be transported efficiently by sea or truck. Once it reaches its destination, LNG is unloaded from ships at import terminals or from trucks at terminals where it is stored as a liquid until it is warmed back to natural gas and sent through pipelines for distribution. With this global increase, Valmet’s valve offering is well-suited to meet the demands for precise control, molecular sieving of impurities and other warm area on/off ESD applications.

The LNG production chain comprises of several stages starting from compression, purification, drying and fractionation to liquefaction before the LNG is ready to be shipped by special LNG tankers and sent to end users.

Before cooling

The numerous impurities that are naturally found in the raw gas freeze at low temperatures and would thus block the cryogenic section of the plant, the gas has to be purified and dried before it can be cooled down to cryogenic temperatures to avoid freezing in the cold section of the plant. The typical method of drying used is a molecular sieve.

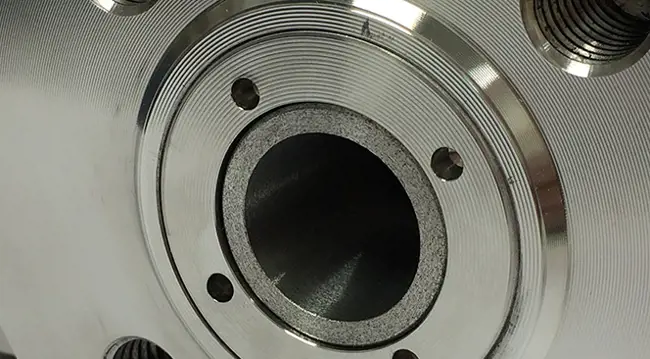

Metal-seated valves, such as NelesTM trunnion mounted ball valves, have been widely used for these kinds of demanding switching applications for their reliable operation and good response with high-pressure differentials. Trunnion-mounted designs give lower friction and operating torque. Seat construction ensures durable tightness in both directions, even in extreme conditions. This design has proved its long-lasting tightness over years of frequent switching with molecular sieve dust present and constant temperature changes.

What are molecular sieve valves?

A typical molecular sieve consists of two or more columns packed with molecular sieves, typically zeolite-based adsorbents. The special characteristics include reversible adsorption of various gas or liquid compounds and a network of cavities and narrow pores offering a very high internal surface area. As the wet or sour stream is processed in one column, the other is regenerating. Depending on the volumes being treated, a multi-adsorber system can be implemented. The molecular sieve adsorbs the impurities in a downflow direction. When the molecular sieve bed approaches its maximum saturation, the inlet stream is switched to the second column and regeneration is started in the first column. Molecular sieves can be regenerated by heating the adsorbent with hot gas, steam, or by changing the partial pressure (pressure swing). Regeneration gas flows counter currently to the process gas at temperatures of 200 – 320 ˚C. Countercurrent regeneration is used to prevent the aging of the adsorbent and therefore enhances the number of cycles. Cooling with dry gas follows regeneration.

The switching valves in molecular sieving play an important role in switching the columns from an adsorption phase into the regeneration and cooling phase in a preset sequence. The valves have to withstand fluctuations in temperature and frequent cycling while keeping the tightness in both flow directions over the years of operation.

Care must be taken in material selection and seat construction in order to avoid any wear with particles coming from mol sieve beds entering the seat cavities and adhering to sealing surfaces. Fugitive emission control is very important in hydrocarbon processing to avoid hazards to the environment and to health.

Metal seated valves, such as Neles’ ball and butterfly valves, have been widely used for these kinds of demanding switching applications. Trunnion mounted ball valves are selected for their reliable operation and excellent response with high pressure differentials. This design has proved its long-lasting tightness over years of frequent switching with molecular sieve dust present and constant temperature changes. It seems to be a trend nowadays, that butterfly valves are considered in certain cases, where the sizes are large and pressures at moderate levels (10 – 20 bar).

Triple eccentric disc designs provide an interesting option for switching molecular sieves. It is important, however to fully understand the process conditions for correct valve selection to ensure continuous drying or separation of fluids for application in question.

Neles double flanged butterfly valve with Neles spring return actuator and Neles smart positioner for rigorous control applications.

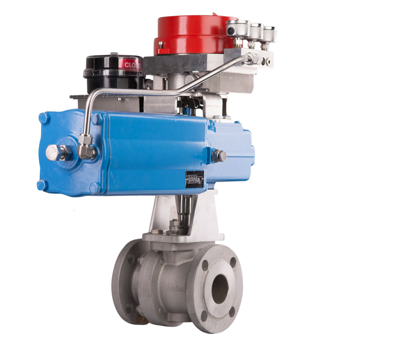

Jamesbury trunnion mounted ball valve with Neles spring return actuator and Neles smart solenoid for ESD applications.

Getting it cool

The liquefaction of methane and ethane with some residual propane takes place in the main cryogenic exchanger. The feed gas is cooled in several bundles after which it is cooled to approximately -160°C. At this temperature the gas condenses to a liquid and is sent to the refrigerated storage tanks. The cooling in the cryogenic exchanger is typically provided by a compression-based refrigeration loop.

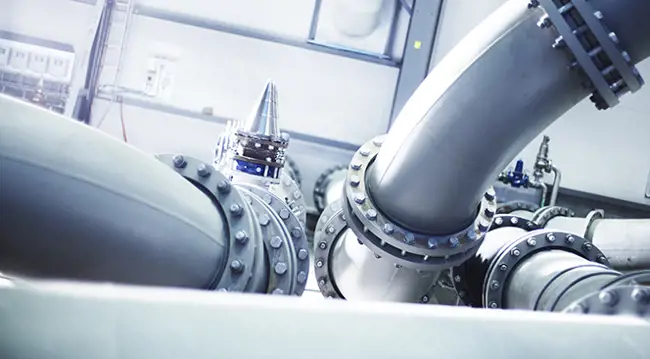

Several control and isolation valves control the levels in vessels, protecting them from overpressure, protecting pumps and regulating flow rates, isolating equipment in shutdowns and start-ups and in case of an emergency. In general, most butterfly valves for this use are 4 inches and larger. Some control valves will be this type, but most butterfly valves are manual, on/off automated and emergency shutdown. While many of these valves are used throughout the facility, most types will be cryogenic to meet the extreme cold requirements. Most of these valves are in the Class 150, 300 and 600 categories with flanged or butt weld ends. The valves will require live loading on the packing to ensure a constant load on the packing chamber. They also will have stem extensions that are calculated in length to maintain a vapor barrier at the upper end of the extension. There are also some higher-pressure valves needed that are in the 900-pound class and are cryogenic butterfly valves, but these are not as prominent for most liquefaction plants. Neles K800 soft seated cryogenic butterfly valves and L6 metal seated designs are used frequently in these applications and have a strong installed base of proven functionality and effective lifespan in service.

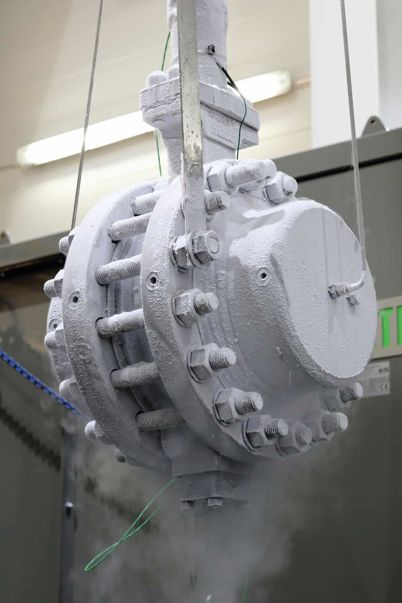

Valmet’s flow control business has rigorous internal standards for cryogenic design and production testing, which is evident in the photo above showing a production cryo test to ensure valve tightness prior to shipment.

LNG flow control

In LNG processing safety and reliability always come first and therefore type-tested products with field proven experience are required. The LNG chain has designated requirements for the area of cryogenic service from production and storage to shipping and re-gasification in receiving terminals. Challenging factory acceptance testing (FAT) is required, mainly for ESD and on-off valves.

Valmet offers a comprehensive line of flow control products specifically developed to overcome the challenges of LNG processing with experience and know-how in these applications. We are also constantly developing our technologies to meet the noise and cavitation challenges.

As a focus of our engineering capabilities, our flow control business has the largest, most sophisticated cryogenic valve testing facilities in the world. It’s in this lab that we verify that our products will outperform in the field according to the specific standards.

Everything from our seat design and coatings to metallurgy have been developed, tested and certified to meet the needs of LNG industry from processing and storage to transportation.

Conclusion

Even though there is a lot of news and hype around the hydrogen economy and energy transition LNG remains a major source of energy. The latest development in Europe with hydrogen economy does not replace LNG in the short-term and there is also expected to be new demand to replace current sources of natural gas.

Valmet offers technology in different phases of the LNG supply chain. Our offering is extremely robust in production, refrigeration, and liquefaction of LNG. The extensive product offering and service support mentality make us a strong partner for all our customers.

As the significance of responsible and sustainable industrial processes increases, the role of green and blue hydrogen as carbon-neutral fuel produced from surplus renewable energy, or through CO2 removal respectively, will continue to grow. However, this does not mean the end for natural gas and LNG which will remain a very important part of the energy mix. LNG is still viewed as the more environmentally friendly solution while the green and blue hydrogen technologies continue to develop.

For Valmet, there is untapped business potential in transport and regasification where we are open to the challenge and look forward to proving it in the years to come.

Sources

- BOYER, J., 'Enhanced Safety in LNG Applications', Valve Magazine, (May 2021).

- TILLEY, M. and BLANQUET, F., 'The Debate and Opportunities Surrounding LNG, Valve Magazine, (2013).

- 'Butterfly Valves in the LNG Industry', Hydrocarbon Engineering, (July 2019), Callum O’Reilly

- Sieving molecules (September 2012).

- European Comission, 'REPowerEU: A plan to rapidly reduce dependence on Russian fossil fuels and fast forward the green transition', (May 2022).

This article has been originally published in LNG Industry magazine's July 2022 issue as ’Control the flow’. Link to the original article.

Subscribe to our newsletter

Subscribe now to our 'Go with the flow' newsletter and receive the latest insights directly to your email.

Subscribe