Uptime leap

Nov 24, 2016

Process safety and reliability create the foundation for sustainable efficiency and productivity in the process industry. Every process owner has strong interest in implementing all feasible measures to better manage and prevent potential risks. Advanced materials engineering solutions have great potential to contribute to the enhancement of safety and reliability in industrial processes.

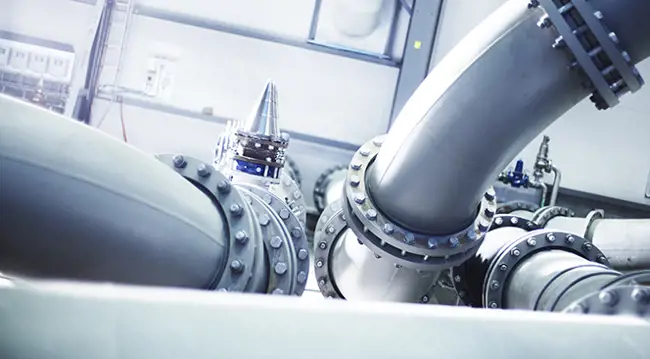

The trend towards more demanding process conditions and tighter environmental regulation further underscores the importance of the reliability and performance of valves and other process industry equipment. If the available raw materials – whether oil, gas, recycled wood, mineral or something else – carry more impurities than acceptable, or the emission control requires use of higher process temperatures, the process owner still wants to ensure that the key equipment in the process is safe to operate, available and able to match the targeted shutdown interval.

Challenging erosion

Careful selection of valve type and sizing of control valves are essential in severe service applications, but avoiding wear damage in the most erosive media requires the use of optimized material solutions as well. Bottom slurries, quench water, and gases containing catalyst particles are examples of media where the valve solutions must combine both enhanced wear-proof materials and manufacturing technologies capable of producing defect-free components. Besides wear, other application-specific requirements, such as resistance to corrosion or thermal shocks, may further limit the feasible construction material options. There is no one engineering material that is superior for all applications, and the optimal selection of valve construction materials typically is a combination of metallic, ceramic and composite materials.

Uptime and capacity

The direct purchasing cost of process devices is often emphasized in investment decisions, although it typically is a minor part of the total cost of ownership; the majority of costs can be attributed to maintenance, repair and operation (MRO). In the worst case, a small savings in purchasing costs later turn into significant expenses caused by excessive maintenance costs or process disruptions that potentially jeopardize the production and operation of the plant. It is challenging to identify and discount all the lifetime costs, especially in greenfield investments, but the strong involvement of experienced process operators, loop tuning engineers and maintenance professionals can help to broaden the picture of usability and costs beyond the initial purchase cost. After all, it is the effective uptime and capacity that maximize the return on investment.

Reliability and productivity

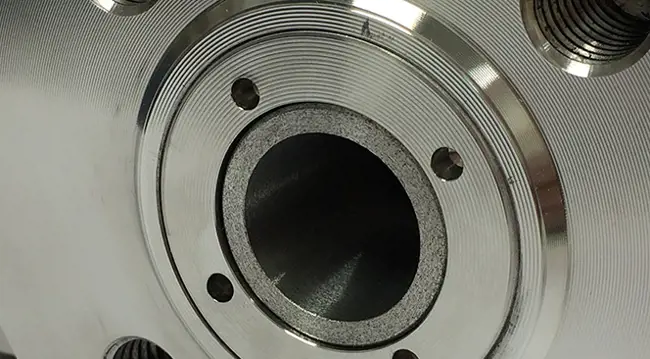

In a bi-metal valve body, a thick (5-15 mm) layer of protective material covers the surfaces exposed to wear or corrosion, while the pressure retaining wall is less alloyed standard material. End-user feedback confirms that the unique MMC (Metal Matrix Composite) materials often extend the effective lifetime of the construction in demanding applications, such as the handling of ceramic catalysts or erosive slurries.

The manufacture of MMC materials and bi-metal constructions is possible with PM HIP technology (Powder Metallurgy, Hot Isostatic Pressing), which secures the bonding of dissimilar materials and eliminates the quality issues, such as porosity, dilution of alloying or micro-cracks associated with traditional cladding methods. The longer lifetime, the extended maintenance intervals, and the constant performance of the Neles bi-metal valves help to drive measurable business results from continuous production processes.

These advanced materials and valve constructions not only offer direct savings by bridging the time gap from premature wear-out to targeted interval of equipment replacements and plant turnarounds, they also contribute to continuous productivity and eco-efficiency of the processes. Even with the higher utilization rate from the investment there are no compromises in safety or product quality, because the reliability and constant performance of these innovative materials and flow control devices make it possible to maintain optimal process parameters longer. The longer effective operating life of valves and their parts decreases unnecessary raw material cycles and the environmental load associated with the processing of excess raw materials. The decrease in unscheduled service and maintenance work lowers the risk to the occupational health of the plant personnel.

The text has been up-dated in July 2020, due to company name change to Neles.

TEXT: Jussi Hellman

Published in Results flow control customer magazine 2/2016.

Jussi Hellman

Materials Engineering Manager, Valve technologies

Subscribe to our newsletter

Subscribe now to our 'Go with the flow' newsletter and receive the latest insights directly to your email.

Subscribe