3 reasons why you need a reliable wet end measurement

Sep 18, 2020

It has been acknowledged for decades by paper and board makers that stable and optimal retention is essential to run their machines at the highest efficiency.

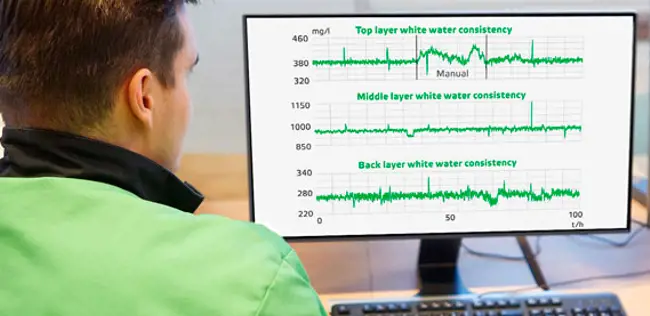

Too high levels and variating amounts of fines, fillers, and chemicals in the white water system is a risk which can cause the accumulation of deposits and create a lot of breaks and web defects. Each paper and board machine have their own individual optimum white water consistency which results in the right retention level. Laboratory measurements by themself do not give you a clear picture of what is happening in your process. But an online measurement will keep an eye 24/7.

1. A stable wet end increases your production and efficiency

By stabilizing and finding the right level of your white water consistency, you will get fewer breaks and a cleaner system. This results in a higher and more efficient production with lower web defects. It is possible to optimize white water consistency differently to every grade and avoid overdosing the chemicals. By stabilizing your retention, there will be lower amounts of fines in the white water. With stable and optimized retention control you’ll get higher and more efficient production while saving money!

2. You can optimize your chemical dosing and not worry about overspending

Automatic white water control keeps your consistency stable. Therefore, you won’t overdose on chemicals by just using the optimal amount. As a result, you will save money by optimizing your chemical consumption and get less disturbance in your production. The only way to optimize chemical dosing and the balance between retention chemicals is by using an online measurement system.

3. Keep it all the time on target with automatic control and focus instead on your production

Automatic control never gets tired. It controls your white water consistency non-stop 24/7 with the reliable Valmet RM3 measurement in place. Automatic controls respond to your process changes immediately, working full-time, and controlling continuously your total consistency. It keeps your process stable even during web breaks. Your production operators get an optimizing tool to run the process as efficiently as they can by relying on the controls. At the same time, your operators can focus on other important things happening in your process.

An online measurement with an automatic control you can trust, keeps your white water consistency optimized for all different grades. Valmet RM3 and Valmet controls are the most reliable solutions in the market when it comes to stabilizing your retention. This solution offers you a fast return on your investment. With Valmet RM3 you can also control your ash from the headbox during web breaks. Valmet has over 40 years of experience in retention management, with major paper and board makers using our solution.