Save costs by optimizing water removal

Apr 5, 2011

Water removal at the forming or press section is significantly cheaper than at the dryer section. Since removing one liter of water from the sheet at the dryer section costs five times more than at the press section, it pays to optimize dewatering at an early stage.

A one percentage point increase in dry solids content after the press section decreases the need for steam at the dryer section by up to five percent. Therefore, it offers a reasonable savings potential or extra capacity in drying-limited machines.

Traditionally, water removal from the web in the press section has been carried out with felts, which mainly remove water with the help of suction boxes (so-called Uhle box dewatering). More than one-fifth of the total energy consumption of the press section is used to produce vacuum; the remaining four-fifths are used by sectional drives. More effective dewatering methods increase the need for vacuum and energy exponentially, as well as shortening the lifetime of the felts, which get worn by friction due to rubbing against the suction box covers.

|

|

Roll-based water removal requires suitable press felts

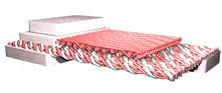

In a modern press section, water is removed from the sheet with a nip load through felts onto roll surfaces, from where it is transfered to save-alls with the help of a foil doctor. Vacuum is mainly needed for suction rolls and suction press rolls. Some suction boxes can even be shut down, which significantly saves energy. Additional savings can be gained through extended felt lifetimes and reduced demand for electric drive power.

One prerequisite for optimal press roll dewatering is that the press felts are suitable for the position in question. Valmet Press Felt AQ, made of non-woven base material, and Valmet Press Felt ECM, made of a combination of non-woven and woven base material, generate higher hydraulic pressures and allow the water to flow easily through the felt onto the roll surface. Correspondingly, there must be sufficient void volume for the water on the roll surface.

The structure of the new Valmet felt types promotes efficient nip dewatering, where water flows directly through the felt without any machine-direction movement. The surface of the felt is smooth against the sheet, which ensures good end product quality and the absence of marking, even with delicate grades. The light, yet tight, structure of the base material shortens the breaking-in time of the felts and thus maximizes the line’s production capacity.

Prerequisites for process optimization and maximal dry solids content

- The press felts need to be suitable for the process in question. For example, Valmet’s press felts allow water to pass through rapidly, and also prevent marking and rewetting.

- The press roll surfaces must be equipped with correctly-sized grooving to ensure enough effective void volume. For example, Valmet Press Roll Cover PF polyurethane cover can handle closely-spaced grooving without breaking.

- Water is removed from the roll surface with effective foil doctors, such as Valmet Doctor Blade Dual*

- All savealls have been designed and placed correctly to prevent rewetting

- The roll covers must be flexible enough to create a uniform nip load

- The suction power of the suction boxes has been adjusted so that the felts are not overdried

Correctly-sized grooving adds to void volume

Water removal in the nip calls for effective void volume on the roll surfaces. Traditional and blind drilling, which is still used, does not provide much void volume, regardless of its seemingly large volume. Correctly-sized cover grooving is a much more effective way to increase void volume.

Too narrow grooves (e.g. 0.5 mm) easily close up under the nip load and can also get clogged by dirt. Valmet recommends closely spaced wide grooves without the risk of shadow marking.

Correctly selected press felts will keep even the most delicate paper grade free of marking under heavy nip loads. Valmet Press Felt TMO and Press Felt SMO feature a special polymer treatment that evens out the nip load and water removal at a micro level, thus preventing marking.

Appropriate totality allows maximal dry solids content

Trial runs and practical experience have shown that raising the web temperature significantly increases the sheet’s dry solids content as the water viscosity decreases and nip water removal increases. A steambox adds dry solids content after the press by up to two percentage points. Replacing suction boxes with optimal water removal through the roll surfaces saves energy and makes mechanical water removal more efficient.

The easiest way to gain savings in energy consumption and wear parts costs through press optimization is to assign comprehensive responsibility for the press section to one supplier. We can deliver extensive know-how and a broad product range for efficient press section water removal.

*earlier known as ValDual