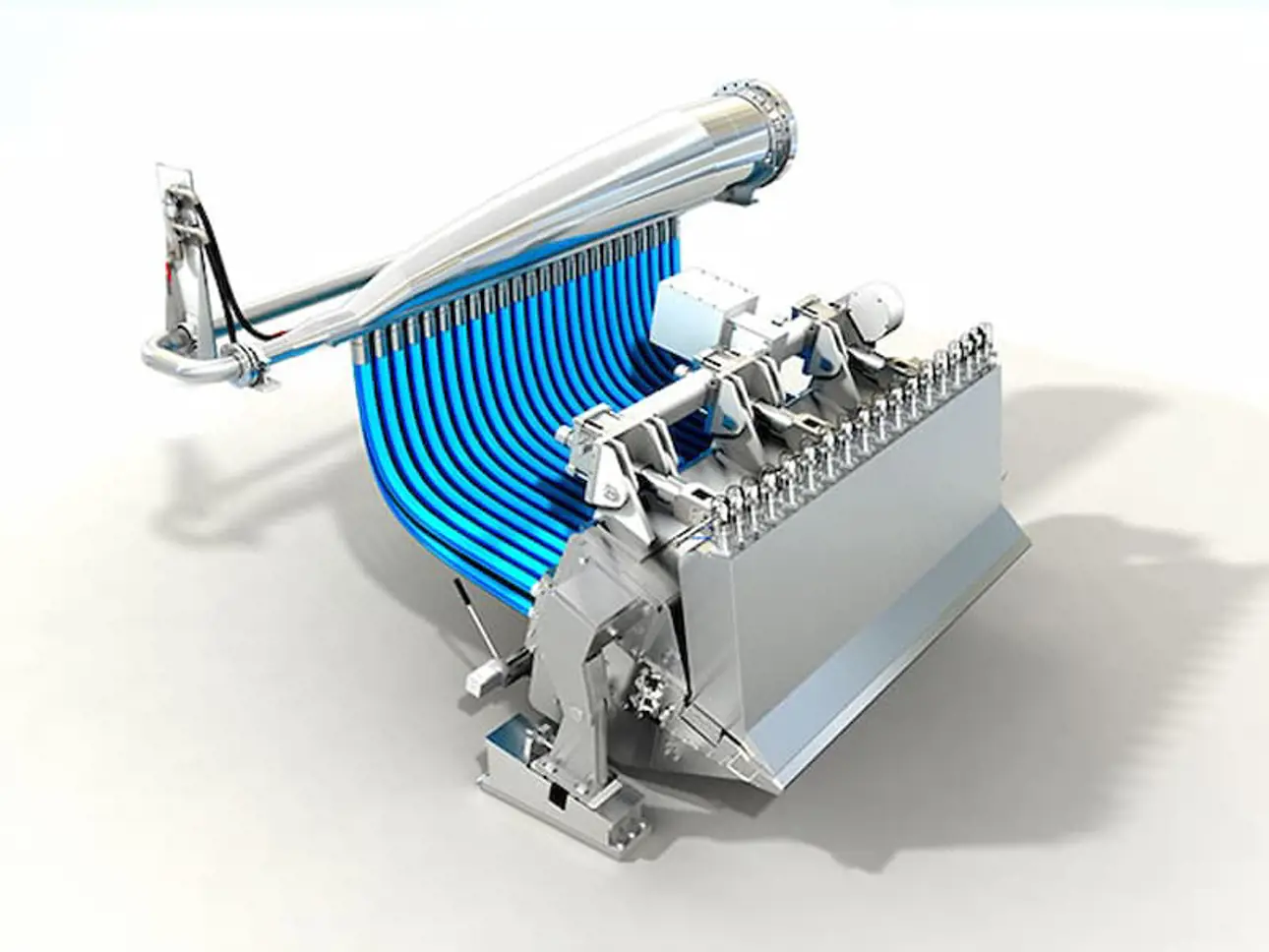

Field services for headbox in tissue making

How to maintain optimal headbox performance?

Regular maintenance for the headbox in a tissue machine is essential to ensure consistent product quality, optimize efficiency and production output, save fibers and energy, and extend the equipment's longevity. By investing in proper maintenance practices, you can enhance the reliability, performance, and profitability of your tissue manufacturing operations.

Consistent basis weight control

Improved formation and quality

Enhanced machine efficiency

Is your headbox properly aligned?

Or are there formation or streak problems? Does your headbox suffer from cleanliness or leaking problems? The headbox performance is highly dependent on the mainteance interval and quality. The headbox mechanical condition study is the most cost-effective approach to evaluating the necessity for service and to identify problems for improving the formation performance.

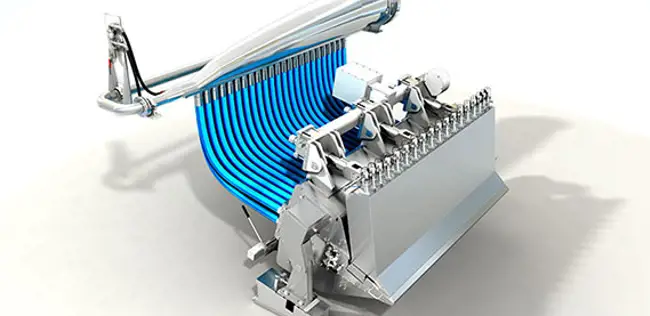

How to eliminate fiber build-up with surface reconditioning

Headbox surface cleanliness is essential to prevent build-up of depostits and to miantain formation. Valmet headbox surface reconditioning is a thorough coating process for your headbox to keep it clean. The MX06 surface treatment leaves a very thin unnoticeable protective coat that is long-lasting and effective dirt repellant surface. It is applicable on all metallic and ceramic surfaces and is highly resistant to detergents, acids and alkali.

Do you want to reduce variations in the profile and streaks in the web?

Deformations in the flow surface, front edge rounding and dents casue problems and difficulties in CD profile adjustment. With our grinding method, the front edge of the apron can be reconditioned to its original accuracy.

The reconditioning can include:

- Apron edge and flow area condition checking

- Apron straightening

- Apron corner and flow surface damage repair by grinding or welding

- Apron surface polishing grinding