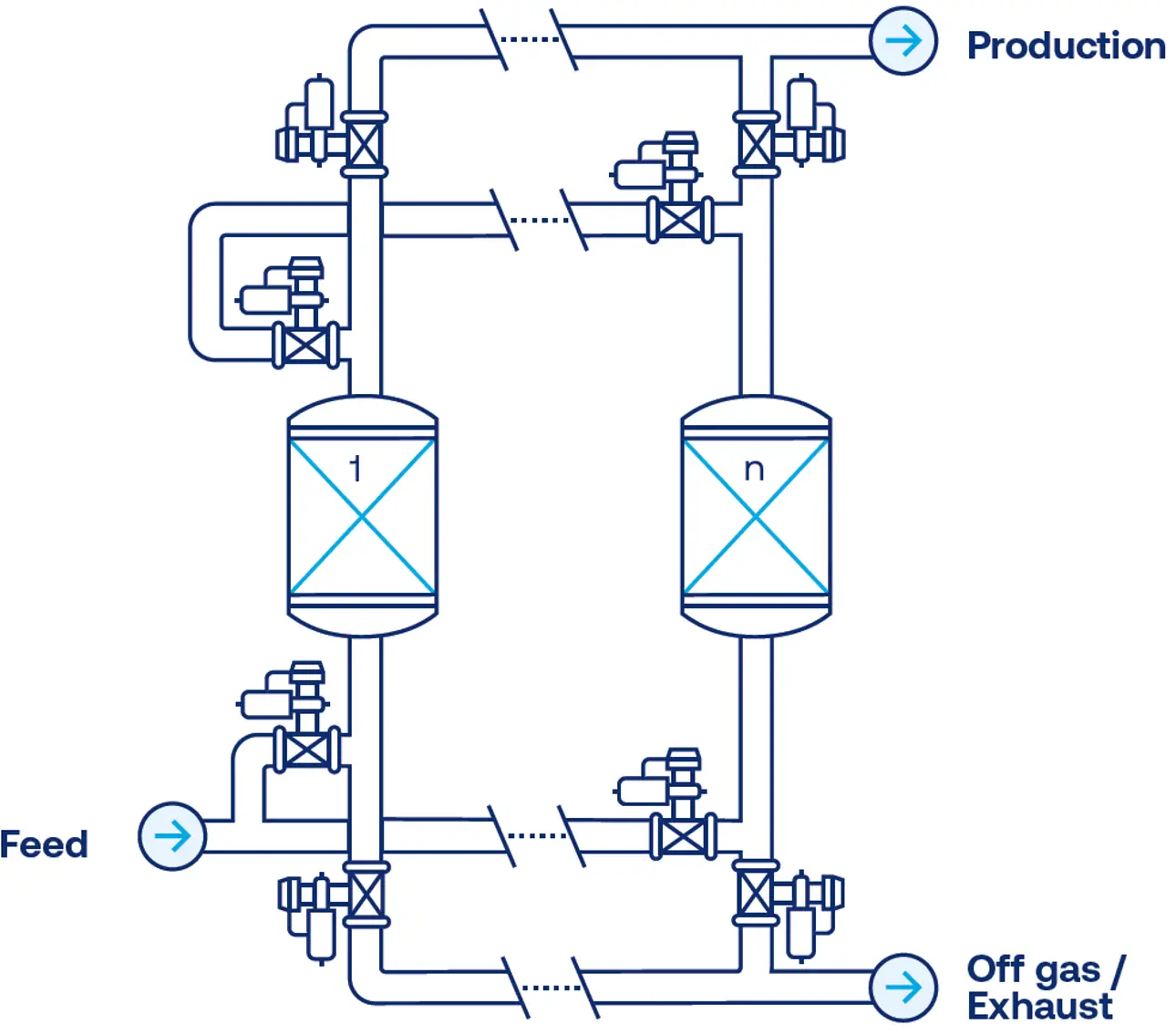

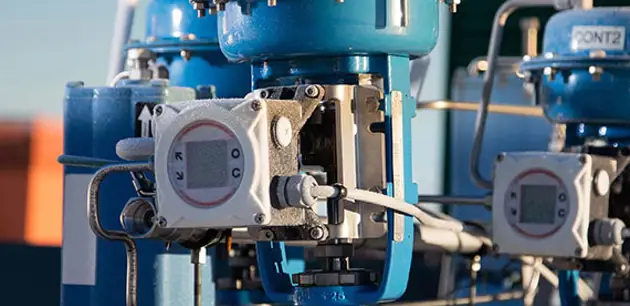

To keep swing adsorption processes running valves must reliably overcome a number of application challenges and process stresses. And, while valves look similar from the outside, few will provide the tight bi-directional shutoff and fast stroking speeds needed for over 1 million of cycles.

Switching between adsorption and desorption demands that valves cycle 2-4 times per minute at a stroking speed of less than 1 second. Given uptime requirements it is common that valves will cycle over 1 million times per year and need to operate reliably between scheduled maintenance intervals. This means valves must be extremely reliable for upwards of 1 million cycles and overcome stress and wear on the valve and actuator. Premature valve wear or loss of actuator torque will cause either a loss of output purity, or worse, an unscheduled maintenance shutdown or hazardous safety conditions.

The differential pressure of this process present another set of challenges. Valves must have tight bi-directional shutoff to prevent leakages that could negatively impact end-product purity. Purity could also suffer as result of inaccurate valve positioners. Either way, despite all the stresses swing adsorption process valves and actuators must operate reliably for over 1 million cycles – no easy task.