Innovative noise attenuating Neles™ Q-Trim technology brings significant savings and improves safety

May 13, 2014

A leading North American pipeline owner was able to solve cavitation, vibration and noise issues in pipeline pump station control applications by installing Neles™ ball valves with Q-Trim technology. Additional bonuses were a safer working environment, better process efficiency and consequently significant financial benefits.

- The customer experienced considerable cavitation, vibration and noise in pipeline pump station control applications, leading to potential damage or destruction of expensive pumps and valves, noise levels above permitted limits, unscheduled process shutdown and inability to meet product delivery obligations.

- Valmet provided the company with ball valves equipped with Neles™ Q-Trim technology.

- Key benefits for the customer include a safer working environment and better process efficiency resulting in significant savings.

There are some consequences that no pipeline owner definitively wants to meet. But with incorrect choice of valves in the pumping stations, a pipeline owner may be faced with potential damage or destruction of expensive pumps and valves, noise levels above permitted limits, unscheduled process shutdown and inability to meet product delivery obligations. And all of these ultimately result in significant revenue loss.

The significant equipment used in pumping stations includes control and measurement systems and instrumentation, pumps and valves. Pumps are typically tens of thousands of horsepower. They can be centrifugal pumps or positive displacement screw type. Prime movers can range from single or dual fuel turbines to electric motors. Valves can be rotary or reciprocating stem type, with typical equipment sizes in the 20 inch and larger range. The investment level in this equipment is significant. Therefore it must be protected from damage.

Demanding service conditions present a significant challenge

Widely ranging service conditions are common. Pressure profiles can include startup pressures of 750 to 1800 psi with associated normal operating pressures of 90 to 100 psi. Temperatures, while normally fairly low, can vary over a wide range and fluid specific gravity can also vary dramatically depending on the exact fluid composition in the pipeline at any given time.

Specifically in this case the valves are applied as Main Line Pump Station Control Valves. Two distinct sets of service conditions exist. One group of valves will handle the ANSI Class 900 applications where the design inlet pressure is 1740 psi. The other group is applied in the ANSI Class 600 applications where the design maximum pressure is 1440 psi.

All of these variables converge and present several challenges. The potentially broad array of fluid characteristics requires final control elements with expansive rangeability. Conditions can cause the fluid to change state by partially flashing to a vapor and could lead to cavitation. Finally, unacceptably high noise levels can be generated with sufficient energy to sizably damage equipment particularly when combined with cavitation.

Control flexibility and fluid handling capability needed

“While the exact savings achieved with our solution are confidential, they are estimated to amount to millions of dollars per year thanks to higher efficiencies resulting from the anti-cavitation Q-Trim technology,” says Kyle Rayhill, Global Business Manager.

Based on achieved results and performance of Neles branded products to expectation, this customer is increasing their installed base of our technology with seven units of 20" ANSI 900 ball valves with standard Neles Q-Trim noise attenuating valve internals.

By reducing noise and related vibration to acceptable levels, Q-Trim technology protects process equipment thus lowering the operating costs and minimizing the need for spare parts for valves and other accessories. This, in turn, means lower total costs of ownership.

Additionally, combining Q-Trim technology with quarter-turn valves results in noise emission levels that meet all relevant industry standards. Additionally, the Neles branded products compact size and wide range of mounting orientations mean less pipeline support and more flexible accommodation of piping layout.

Control valve noise can be eliminated before it is created

With this customer as with others, too, the most significant source of control valve noise in liquid applications is cavitation. Noise produced can be abated in two ways. One is to modify the valve and the trim so that cavitation intensity is reduced or prevented (source treatment). The other one is to dampen the generated noise (path treatment).

Out of these two forms of noise abatement, source treatment is preferred whenever possible. Using it, high mechanical vibration that accompanies noise can be prevented. The resultant benefit is predictable, reliable process operation.

“It really pays off to deal with the noise problem even before it is created; it is possible with our advanced noise attenuation technology. Elevated control valve noise in the throttling process can be harmful not only to the employees and surrounding communities but it can also seriously damage process equipment. And once noise is created, it is hard to eliminate,’’ Rayhill points out.

Industry benchmark solution for challenging noise attenuation

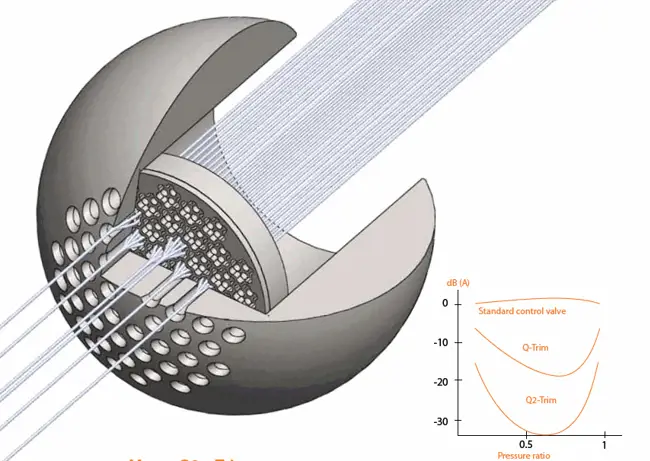

For more than 30 years, our patented Q-Trim technology has been the industry benchmark for rotary noise attenuation solutions in challenging applications. Recently we have added a new level of performance by introducing the Neles™ Q2-Trim that solves aerodynamic noise problems and reduces noise up to 30 decibels compared with a typical control valve.

The front running Q-Trim technology is combination of various techniques, including pressure staging, flow division, peak frequency shifting and velocity control. Their ingenious combination results in multiple benefits for the users. It eliminates the damage that high noise can cause to process plants, employees and surroundings. Q-Trim contributes significantly to a safe working environment, process control stability and longer uninterrupted plant runtime.

Noise attenuation for a wide range of industries

In addition to the original Q-Trim technology that was applied in this customer case study, we added the new Neles™ Q2-Trim thereby extending the family of Q-Trim product capability up to 30 dbA. The full range of Neles™ Q-Trim is available for pressure classes ANSI 150 through 900 in sizes up to 36”.

Text originally published in 2014, and slightly updated in April 2022, due to the company name change to Valmet.

Subscribe to our newsletter

Subscribe now to our 'Go with the flow' newsletter and receive the latest insights directly to your email.

Subscribe