Unlocking the role of AI in modern manufacturing

Dec 4, 2023

Artificial intelligence is reshaping the manufacturing and industrial landscape, transforming traditional processes. We explore the strategies being used to drive this change.

The manufacturing and industrial landscape is significantly transforming as artificial intelligence (AI) takes center stage. As it ushers in a new era of efficiency, innovation, and digital business models, manufacturers increasingly recognize AI’s role in reducing energy consumption and increasing profitability per hour.

However, industry experts note that it is not about adopting technology without a specific purpose or goal but about aligning it with particular use cases and broader business objectives. Let's explore how AI drives this change and the strategies used to make it happen.

The transformative power of AI in manufacturing

Implementing technology without purpose lacks value. Because it is merely one tool among many, it is essential to investigate the practical benefits and adaptability of integrating AI-driven systems in manufacturing. In their ongoing partnership spanning five years, Amazon Web Services (AWS) has been instrumental in helping Valmet on its Industrial Internet journey, emphasizing the significance of aligning technology with specific use cases and business goals.

Douglas Bellin, Worldwide Head of Smart Manufacturing at AWS, points to the successful implementation of AI by a multinational beverage company, which integrated thousands of sensors into its production lines to provide valuable data for process optimization.

He says that while individual data points can improve processes, the true value lies in combining and analyzing data from these sensors: “The company leveraged AI-driven sensor data analysis to gain insights, resulting in notable enhancements to their cleaning-in-place (CIP) scheduling. This led to a substantially reduced water and power consumption and an almost 30% increase in production line availability.”

Overcoming common challenges in AI adoption

One common misconception among small and mid-sized manufacturers is the belief that leveraging AI requires substantial resources, such as data scientists and access. However, the challenge often lies in generating significant data volumes that often go untapped, remaining unused and stagnant due to limitations.

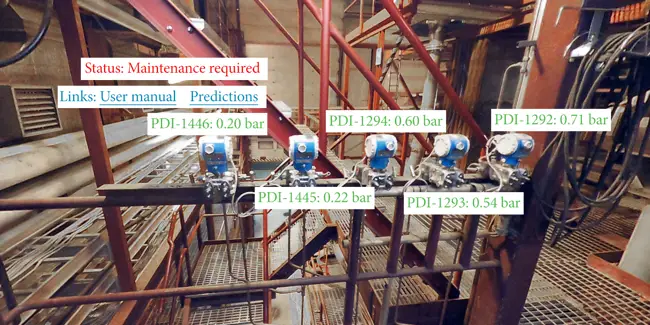

Process industry manufacturers looking to embark on the AI journey should take the first step without delay, urges Bellin. “AWS offers user-friendly services designed to simplify the identification of equipment anomalies and aid predictive maintenance. They allow customers to input their datasets and automatically apply algorithms to detect abnormal behavior, improving equipment uptime and reducing unplanned downtime.”

As a leading provider of process and plant control solutions, Valmet understands the importance of establishing a solid foundation at the outset of the Distributed Control Systems (DCS) and data management enablement journey.

Vice President of R&D, Automation at Valmet, Jukka Ylijoki, says, “By leveraging cutting-edge technologies and expertise, manufacturers can accelerate toward AI-driven operations. This proactive approach enhances equipment uptime and significantly reduces unplanned downtime, leading to increased operational efficiency and cost savings.

Moreover, Bellin stresses that ensuring operational data security is crucial in AI. “With generative AI, the right question could initially uncover your intellectual property, such as data outlining your unique intellectual process. It is important to ensure data security while enabling pre-trained models to unlock new insights and capabilities, safeguarding your information. At AWS, security is paramount, and we help our customers implement secure strategies and well-architected reviews of their technology stacks to meet this need.”

AI's role in enhancing industrial processes

AI is not meant to replace traditional solutions in manufacturing; instead, it complements existing technologies to offer distinct benefits. “As a customer, it's just one tool in the technology toolbox designed to enhance the quality of their products,” says Katja Kujala, R&D Manager, Industrial Internet at Valmet.

For example, one of Valmet’s cutting-edge technologies employs machine learning in camera systems. These systems can be customized for numerous applications, including pattern recognition and fiber analysis in mills. The system is trained to recognize faults in paper and fiber types, providing valuable information for manufacturing controls and laboratories.

Ylijoki says the system is trained to detect predefined conditions, enabling abnormality identification. “In the past, quality control issues led to problems in subsequent processing stages due to a lack of information on quality faults. This marks a new era.”

Kujala notes, “Addressing deviations, identifying abnormalities, and understanding their root causes present an intriguing challenge, especially in various customer settings. This forms a pivotal part of our drive to advance technologies and tools for autonomous operations. Expanding our AI-related toolset necessitates a shift in how workers adapt to these tools, highlighting the importance of change management.”

While complete automation is feasible, Ylijoki says that AI technologies will have a significant role, with systems capable of assisting people to the extent they desire in this development journey: “However, humans should retain a sense of control, even in highly automated scenarios. We will continue on our journey towards increasingly autonomous mills but the mills should not become entirely machine-controlled.”

Text: Asa Butcher

The images of this article were generated with Artificial Intelligence.

Related articles