How process automation can stay ahead of disruptive technologies

With generative AI and other disruptive technologies making headway, staying ahead of the curve is vital for process automation. Nokia’s Emre Aksu and Valmet’s Mika Karaila explain how to future-proof your business.

Technology is advancing at lightning speed. Artificial intelligence (AI) applications like ChatGPT, digital twins and edge computing are drastically changing how we work and manage operations. Breakthroughs in generative AI have been compared to the advent of the internet. Even the metaverse that has faced skepticism has pushed companies to gear up for its possible applications.

So how can companies prepare for and future-proof against these advancements? And what disruptive technologies are currently challenging process automation?

Computing and data heading to the edge

Emre Aksu, Distinguished Research Manager at Nokia, says one of the challenges many industries face is the amount of data that should be processed and utilized, as well as finding smart ways to deliver the necessary data to the workforce without delay.

“Workers shouldn’t be cluttered with information. How we retrieve it should be seamless. The metaverse is one way to solve the issue,” Aksu believes.

“With digital twins, we can build digital infrastructures based on our existing ones to control workflows in a virtual environment.”

In the future, there will be a great need for private 5G networks to solve security and coverage issues and for location awareness. Hardware and computational power are also required for these ongoing technological shifts.

According to Aksu, edge computing, or IoT edge processing, is an emerging trend changing how data is processed.

“One paradigm shift for companies is utilizing these edge technologies. Deploying computational power on edge means processing data near where that information was generated, like a device or vehicle. One such example is edge processing of real-time industrial 360-degree video data for situational awareness. Another very important emerging technology is Edge AI.”

Towards the industrial metaverse

Regarding maintenance and field services, Mika Karaila, Research Director at Valmet, sees great potential within the industrial metaverse. “The data will grow, and it needs to be used somehow. Much is happening on site, and the industrial metaverse could help manage it all,” he envisages.

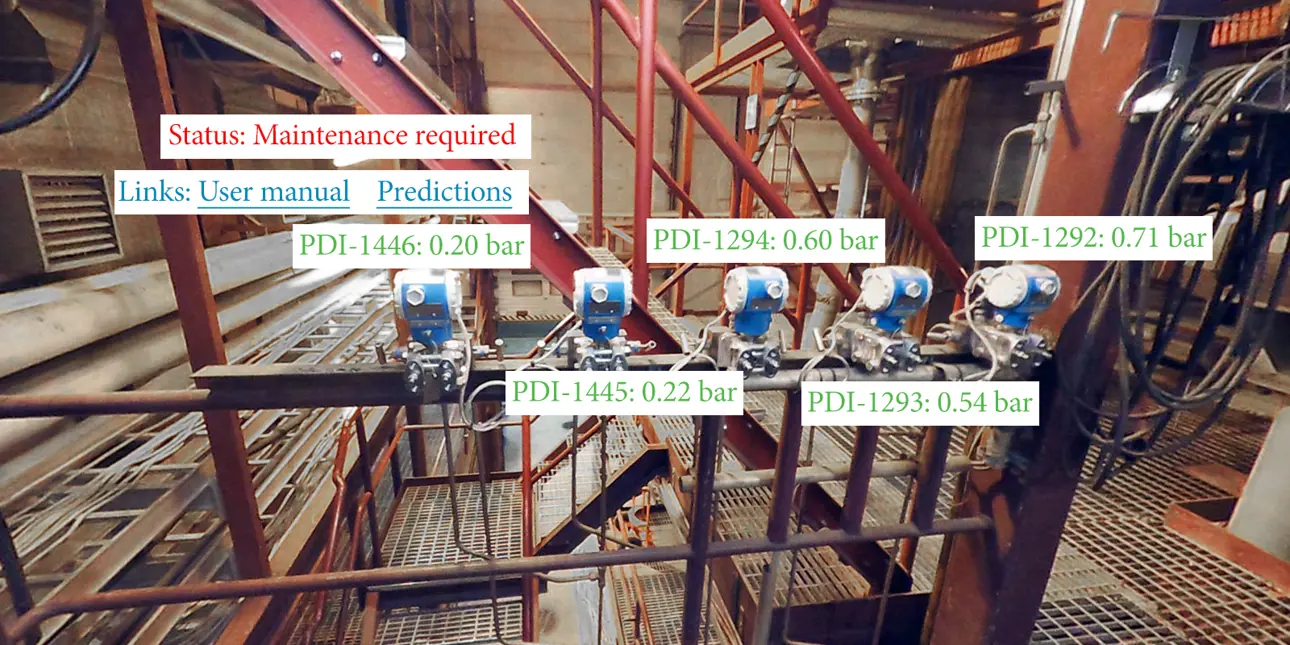

The metaverse is not only a virtual layer that can benefit the entertainment or marketing industries. Karaila has been experimenting with a prototype of an industrial metaverse – a virtual representation of the physical world used for industry-specific purposes, such as maintenance or detecting anomalies in mill operations.

“Our web-based prototype is the start of an industrial metaverse that we have used on a mobile device. It’s based on GPS information of the locations of different machinery, enabling the user to see a live status along with other data. Using deep links, we can provide access to asset management, distributed control system or predictive maintenance solutions,” Karaila reveals.

The industrial metaverse has many potential applications, such as remote collaboration, maintenance, and product design. Many companies are now using the technology to simulate complex industrial processes that could radically increase efficiency.

“Each physical element has a digital twin that can be based on image anchors, for instance. Thanks to AI and camera technology advancements, more companies are now launching visual positioning systems to track operations,” adds Karaila.

Uses and applications for generative AI

ChatGPT and other generative AI programs have been making headlines since their launches. Valmet’s digital assistant, which includes models of maintenance reports, is a similar machine learning model. It helps locate the information you need from past reports and provide answers on how to proceed with a given task.

“It’s like ChatGPT for Valmet’s maintenance. By offering a huge data bank powered by AI, it can in the future bridge the gap between the retiring maintenance staff and the new workforce,” Karaila explains.

Aksu believes algorithms like ChatGPT and DALL-E have huge potential, but at the same time, we should remember that these are AI systems trained with data.

“If the data you feed into it is only publicly available, like from internet pages, then the system has less information about a particular industrial context. Given the right data, the system could be valuable in acting as an assistant for decision making. Nevertheless, I expect many spin-offs with generative AI as the tech continues to evolve,” notes Aksu.

Cultivating innovation

When new technologies arrive, it’s essential to act fast and be prepared to adopt technologies that support innovation. At Valmet, the way to stay ahead of disruptive technologies has been the constant flow of prototyping to ensure the ability to react quickly to market and tech development changes.

“By closely monitoring the tech landscape, we can rapidly innovate before the moment arrives. Testing the maturity of the technology with prototypes and always having enough people to develop a new product has always been our approach,” Karaila says.

Fuelling innovation and finding new ways to use technologies such as AI, Valmet joined forces with Nokia Technologies along with other partners in the AISA (AI-based Situational Awareness) project. Aksu is confident that these collaborations are an excellent way to investigate new technologies that would improve efficiency and productivity of industries.

“When industrial partners, technology developers, product providers and academia work together, your solutions will make more sense,” Aksu says. “Companies must be open-minded and proactive. Instead of waiting for the solution providers to come to them, they should identify what they need by prototyping and exchanging information with others.”

Text: Sini-Maria Melanen