Machine automation services

Valmet’s paper automation services offer paper and board makers unique automation expertise that goes beyond just technical know-how. The services integrate safety, processes, and machinery for improved control and higher reliability.

Increased availability and reliability

State-of-the-art technology

Problem-solving solutions for a variety of automation platforms

Automation solutions for several platforms

Our automation solutions include studies, upgrades, replacements, process improvements, and integrated projects. Valmet’s paper automation services provide problem-solving support for a number of different automation platforms, always according to customer needs.

Why choose Valmet's machine automation services?

- Increased availability and reliability

- Access to profound machine and process expertise, including hydraulics and lubrication

- State-of-the-art technology

- Problem-solving solutions for a variety of automation platforms

- Experience from a large installed machine base

- Remote and after-sales support

- High dedication to project management and start-ups

Automation study

The automation study identifies the level and performance of existing machine automation.

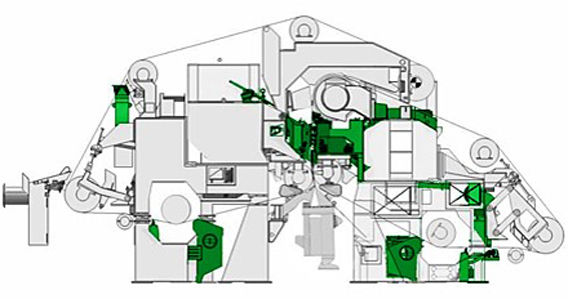

Paper and board machine automation upgrades and replacements

The runnability of machines and the availability of automation equipment can be improved through upgrades, extensions, or replacements of PLCs, HMIs, PCs, black boxes, and machine controls. Obsolete components and electronics are replaced with up-to-date technology.

- Arcos oscillator upgrade

- Embedded I/O card (EIO) upgrade

- Headbox edge flow valve upgrade

- Headbox attenuator level control upgrade

- Hydraulic valve upgrade

- Machine control system (MCS) upgrade

- Moog PSC2 controller upgrade

- Non-Valmet zone-controlled roll control upgrade

- PosiEdge to Valmet Ultrasonic Fabric Control upgrade

- Valmet Shoe Press Roll control modernization

- Valmet Shoe Press quick unloading solutions

- Valmet Suction Roll Seal Strip Control upgrade

- Valmet SymZS Nip Roll optimization PC upgrade

Process and production improvements

Automation hardware and software, such as web break detectors, pick-up sequence improvements, and measurement systems, enable better process handling and improved runnability.

- Valmet Shoe Press Delamination Detector – measuring system for shoe press sleeve delamination

- Valmet Return Oil Particle Analyzer – measuring system for detecting metal particles in the oil

- Dynamic felt oscillation – ensures a homogenous press felt surface in the sheet area

- Pick-up sequence improvement – improves web transfer to press section

- Dynamic Diagrams – dynamic hydraulic and pneumatic diagrams for fast troubleshooting

- Valmet Break Detector Far – detector especially for sizer area

- Valmet Break Detector Cross – detects break from free draw

- Valmet Break Detector Pocket – detects break from the roll surface

- Valmet Press Nip Loading System – nip loading system modernization for deflection-compensated Sym/CC rolls

- Valmet Release Point Detector – center roll sheet release point measurement

- Valmet Oil Lubrication System T – optimized lubrication oil flow

- Valmet Ultrasonic Fabric Control – non-contacting fabric positioning solution

Integrated projects

Automation modifications and upgrades together with machine improvements or relocations are always implemented according to customer needs. Integrated automation projects vary from individual components or principle drawings to full-scope automation deliveries of entire machine section rebuilds.

Case: PLC upgrade at Stora Enso Skoghall board machine 8, Sweden

We have had a good working relationship with the Valmet check-out team during rebuilding, check-out and commissioning. The system solution and its rebuilding turned out well, and our operators are very pleased with the HMI panels. All the people involved from Valmet deserve big thanks for a well-executed project.”

Questions?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact us