Valmet Evolution Defibrator

Valmet EVO Defibrator is the most innovative and cost-effective Defibrator in the market. The Defibrator is used for processing wood chips or other fibrous materials into fibers that are used for e.g., manufacturing of MDF, insulation bord and high kappa fibers etc. The Refining of fibers at steam pressure was patented by Valmet 1934 known as the Defibrator™ process. A Defibrator and refiner are in principal the same machine but the name Defibrator is protected.

Since launching, the EVO series has been expanded to include EVO models with segments ranging in diameter from 46 to 74”. Since its launch at Ligna 2005, the EVO series has been a great sales success due to its energy saving ability.

Major energy savings

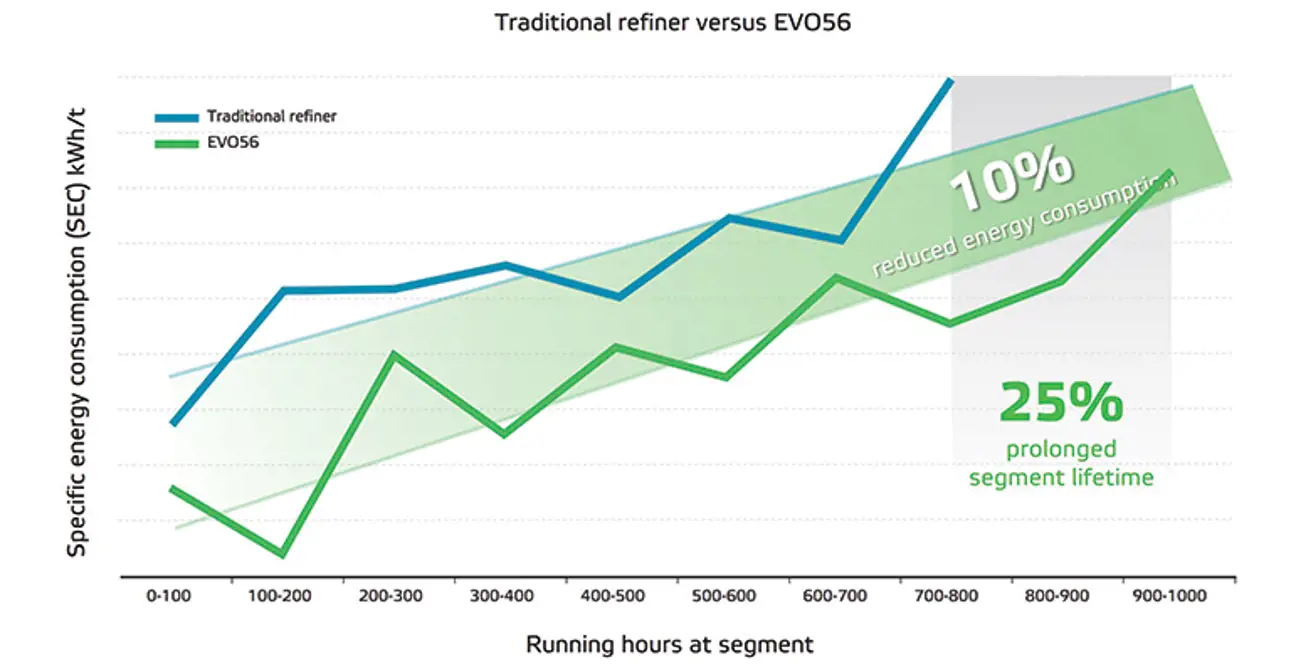

Our EVO family Defibrators have all reduced the specific energy consumption with minimum 10 % compare to the other system and is one of the reasons why customer choose Valmet. The energy savings comes from good distribution of chips in to the grinding zone (wings at feeder), better distribution of fibers between the segments (due to even pressure distribution inside the housing), more efficient fiber flow out from the housing (helical housing), lower friction in bearings (as a result of roller bearings compared to hydrodynamic

bearings).

Revolutionary design

The key features of the EVO-series Defibrator is the advanced helical discharge from the refiner housing as well as new refiner segment technology, a new roller bearing system with zero axial play, an exterior design that contributes to thermal stability and perfect parallellity during operation. The design is made for good access to enable easier and quicker maintenance, i.e change of segments. The EVO Defibrator system also includes a new high-capacity and high dewatering plug screw feeder system with a dewatering plug pipe.

Superior infeed geometry

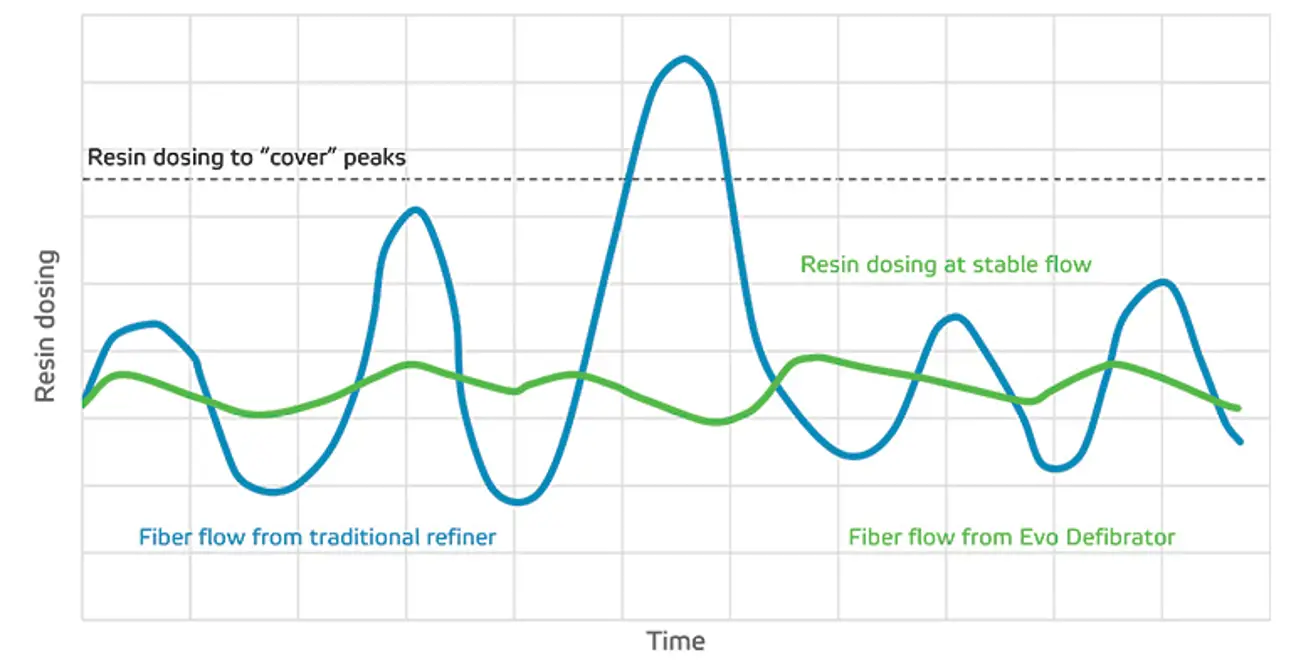

The new Defibrator features a highspeed feeder that, combined with a new infeed geometry in the coarse breaker bar section of the segment area and a high performance center plate, provides for an unique low energy and smooth, uniform furnish flow into the fiber-grinding zone. The flow pattern of furnish, steam and fiber in the refiner is essential in the fiber preparation process. Smooth, uniform infeed and discharge not only influences fiber

quality but also the consumption of electric energy for grinding, steam consumption for discharge, resin consumption and dryer energy consumption.

Unique helical discharge

As a result of the latest development in low-energy unidirectional refiner segments, Valmet has developed a unidirectional refiner-grinding house. The helical fiber path combined with a blow valve that opens in the direct fiber flow facilitates smooth discharge possible without any loss of energy due to turns or choking of the fiber flow. The optimized spacing around the rotor combined with highly effective rotor wings minimizes fiber buildup in the housing. Operation with this geometry – with normal unidirectional segments – creates a specific energy saving of more than 10% for the same fiber quality.

Focus on reduction of production cost

Development of the new generation Defibrator focused entirely on enhancing efficiency to maximize energy reduction and ensure minimum resin consumption. Experience from the L, M and P series was the basis for the practical operational and maintenance improvements when the new, evolutionary EVO-series Defibrator was being designed.

Customer case: Finsa, Padron, Spain

In 2005, Valmet, together with Finsa Group in Spain, replaced a traditional Defibrator with a new EVO56. All process parameters and equipment including segment pattern were unchanged. Results showed that the new EVO Defibrator saved approximately 10% specific energy on average and increased the refiner segment lifetime by 25%.

Customer case: Medite MDF, Clonmel, Ireland

In 2008, Medite in Ireland replaced two old Defibrators with two new Valmet EVO Defibrators. The much more stable fiber flow from the new machines, permits lower resin input since the need of covering for peaks is no longer required. Results demonstrated the ability to reduce resin consumption by more than 15%, and at the same time, lower energy consumption considerably.

Material available for download |

||

|---|---|---|

| Evolution Defibrator | Reference - Medite MDF, Clonmel, Ireland | |

Valmet Evolution Defibrator series

Evolution Defibrator series include models with segments ranging in diameter from 46 to 74”

Our expertise is at your service

Our focus is to bring your performance forward utilizing our extensive experience and in-depth knowledge of pulp process technology. Get in touch with our experts through your local Valmet office, or the link below.

Contact us