OptiSizer Curtain

Improving strength and surface properties

The new, innovative surface sizing method applies the starch as a curtain of size. When the application method is combined with hard-covered nip rolls, which ensure a good penetration of starch, the results in coated cartonboards production are significant: stiffness, quality and production values can be increased, and energy and raw material consumption reduced.

High production capacity and stiffness

Less drying and improved runnability

High surface quality and flat topography

Energy and raw material savings

New application method

A new size application method where size is applied as a curtain flow on hard-covered rolls makes it possible to produce high quality coated cartonboards with enhanced properties. The new curtain sizing process has already been demonstrated repeatedly at Valmet’s Paper Technology Center pilot trials. High increase in board stiffness values have been reached with curtain starch application.

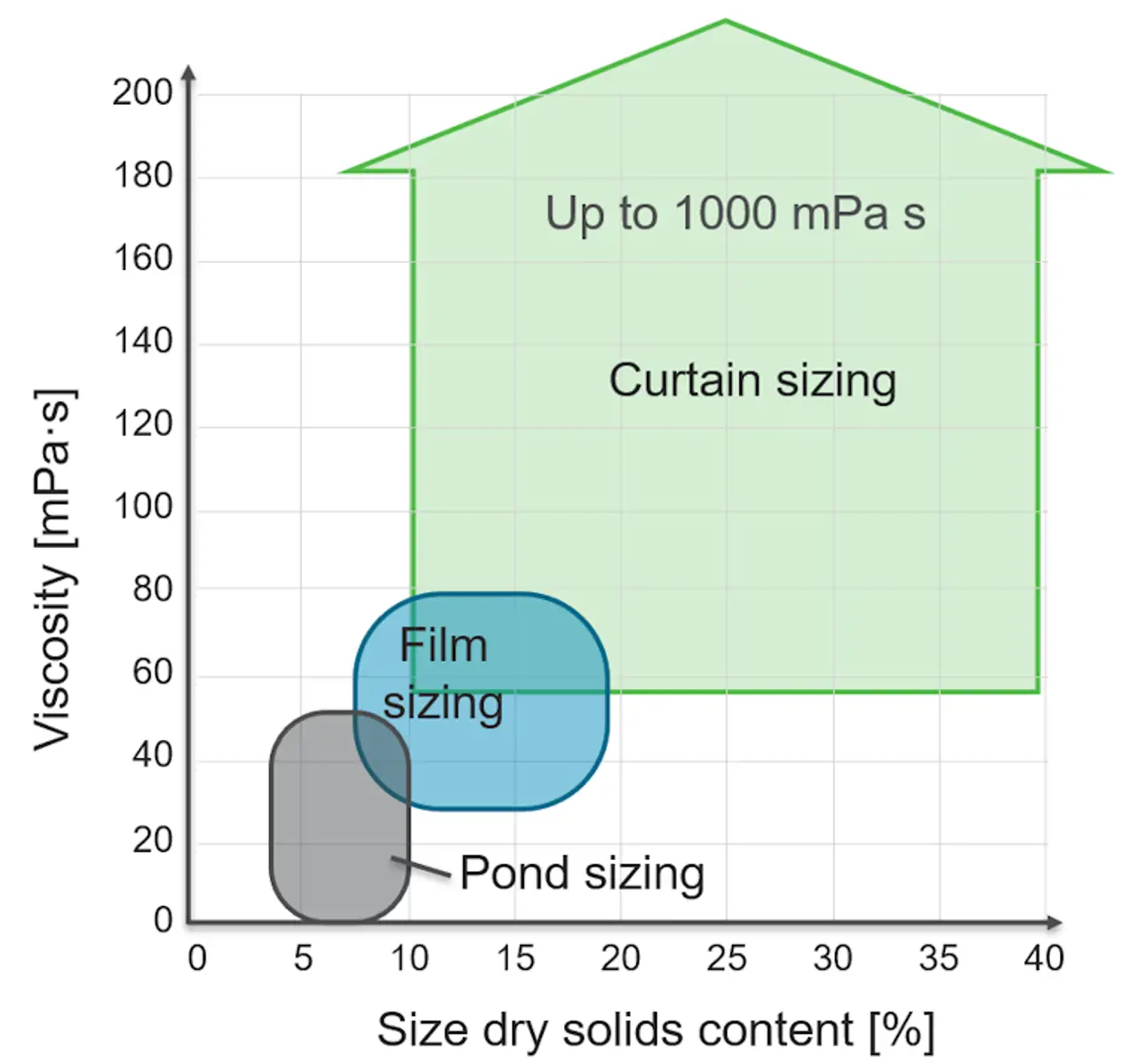

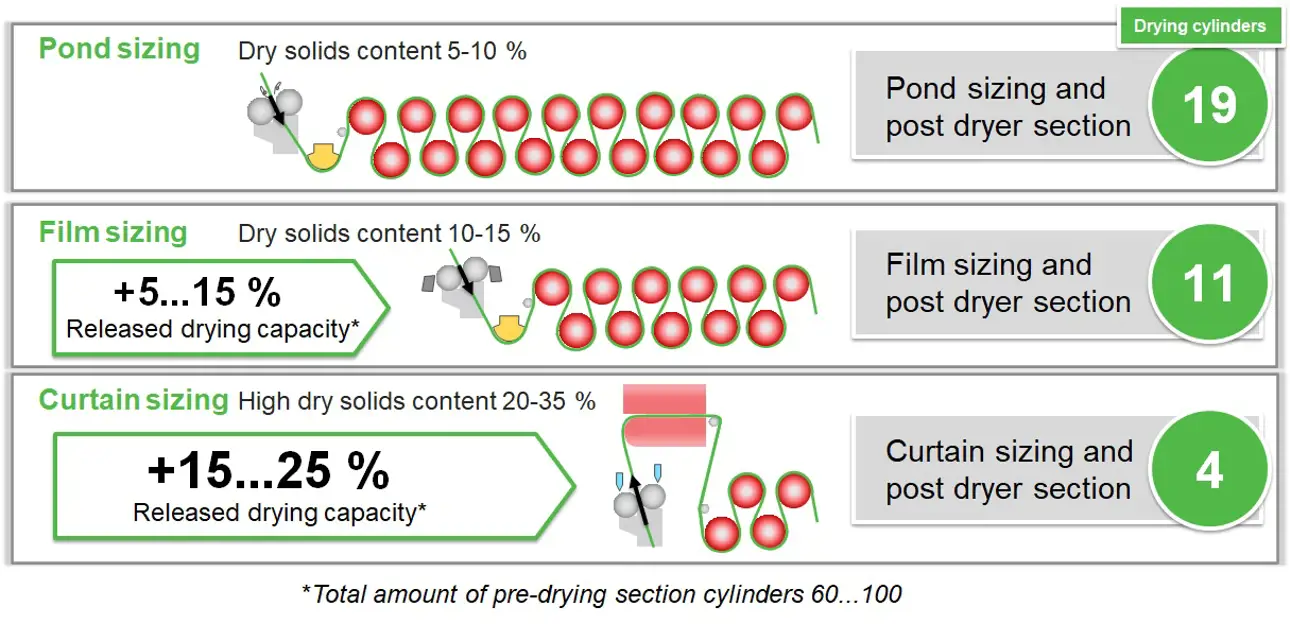

The application beam forms a curtain of starch on roll with high solids and viscosity, which gives totally new operating window for sizing compared to pond, film or spray application as seen in Figure 1.

Figure 1 (a and b). Operation window of sizing with curtain application (curtain sizing), size can be only starch or combination of starch and other components, like hydrophobic size, pigments and dyes

As high starch solid contents (20-30%) can be used with curtain application giving the opportunities to improve runnability of size press (less wetting of sheet) and to increase savings in drying energy. Reduction of wetting and increased pressure in the nip also reduce or eliminate the unwanted roughening effect of sizing. Consequently, very good surface smoothness and topography are achieved, which might lead into a possibility to reduce the amount of coating color.

Cartonboards with enhanced properties

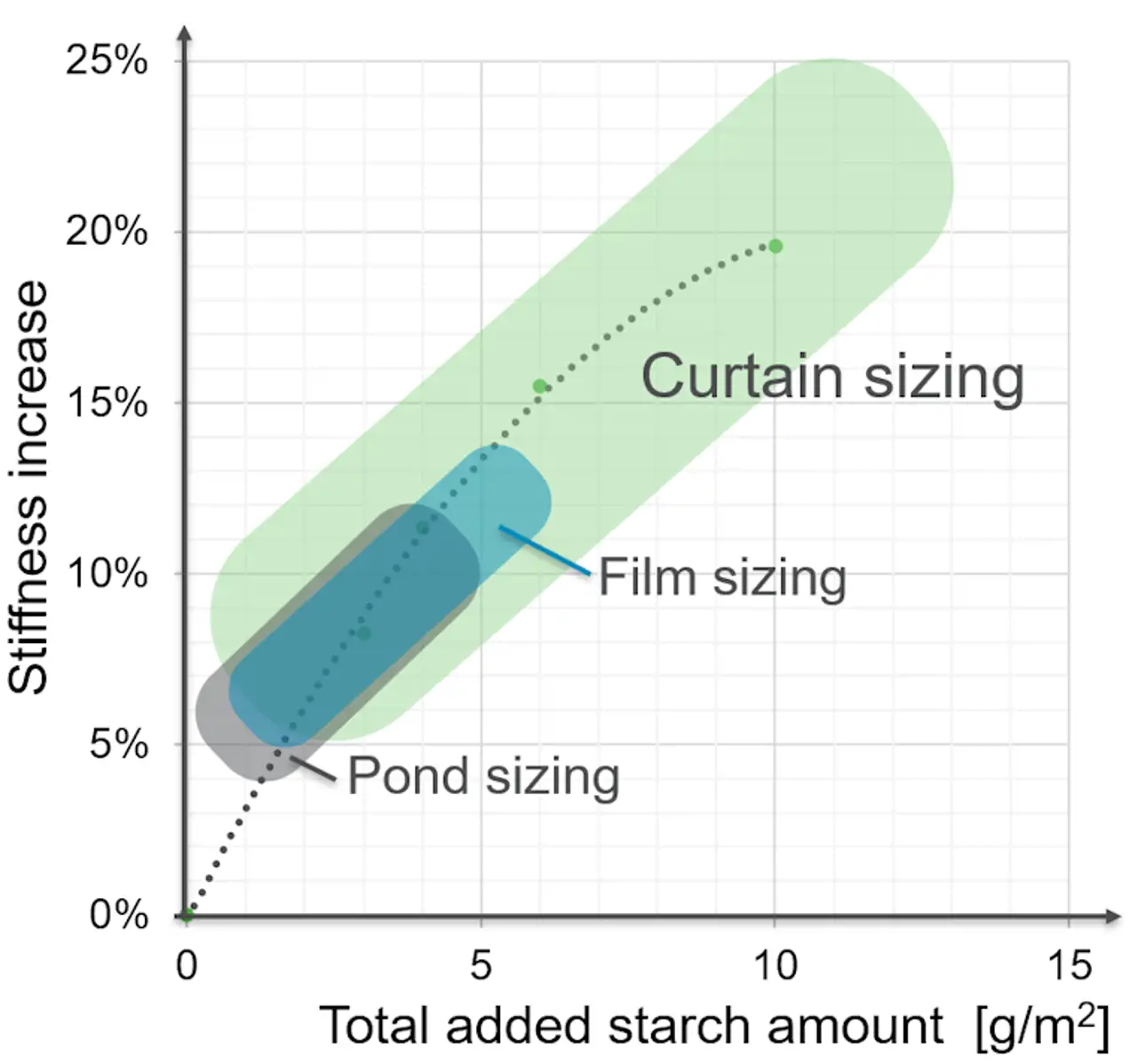

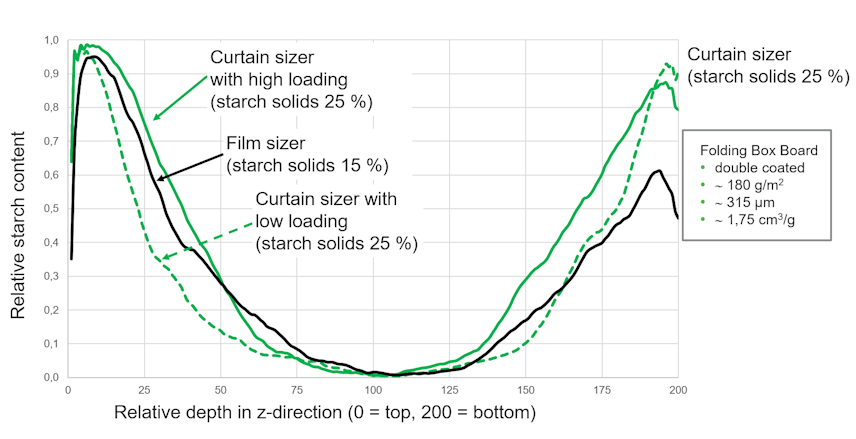

The new opportunities in size composition with curtain application make it possible to produce coated cartonboards with enhanced properties. The optimized balance between size coverage and size penetration can be adjusted by nip load in curtain sizing. For example, low pressure in sizing can be used to maximize board stiffness, and high pressure can be used, if the target is to increase ply bond or internal bond, see Figure 2.

Figure 2. Z-directional distribution of starch

Want to talk to our sizing experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsNew materials in size

Curtain sizing will give opportunities to mix new materials in size with no risk of plugging rods. Such opportunities include, for example, adding highly refined fibers, micro or even nano-scale fibrillated cellulose to sizing process. Of course, chemicals and pigments, which are already being used in sizing can be also applied with curtain sizing process, like, GCC, clay, hydrophobic sizing agents, color dyes or barrier chemic, etc.

Combining sizing with long nip metal belt calendering

When the new sizing process is combined with metal belt calendering (OptiCalender Metal Belt) with a long nip, the stiffening effect is further improved. At the same time, the topography and smoothness of the sheet are improved significantly. The effect of metal belt calendering is based on high amount of heat transferred from thermo roll and metal belt to the board web. This combined process of curtain sizing and metal belt calendering has a potential for a completely new performance level of coated boards, see Figure 3.

Figure 3. Different sizing application methods with drying and calendering

Want to know more about metal belt calendering?

Read more about Valmet's unique metal belt calendering

ExploreHow to plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. Download our e-book to learn more.

Download e-bookPlanning a grade conversion?

The world is changing fast; the consumption of papers is decreasing and boards increasing. Update your paper machine with Valmet to produce more profitable products.

Discover moreExplore our latest board and paper press releases

- Jul 8, 2024Valmet to supply operator training simulator to Graphic Packaging International in Waco, Texas, United States

- Jul 8, 2024Discover Valmet MTC Wizard at Tissue Innovation Days 2024: the latest technology enhances Client benefits in Tissue Folding

- Jul 2, 2024Valmet to supply a high-capacity winder to Wuzhou Special Paper in China

- Jun 26, 2024Valmet to supply both a papermaking line and a paper machine rebuild to a customer in Asia-Pacific

- Jun 25, 2024Valmet to deliver a tissue machine to Andhra Paper in India

- Jun 19, 2024Valmet receives the second order of converting lines to Metsä Tissue in Mariestad, Sweden

- Jun 13, 2024Valmet and Flootech enter partnership to advance water treatment for the board, paper and tissue industry

- May 30, 2024Valmet enters joint venture with Körber to advance the digital offering to the tissue industry

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China