Flame detection for grate combustion management

Valmet Grate Combustion Vision

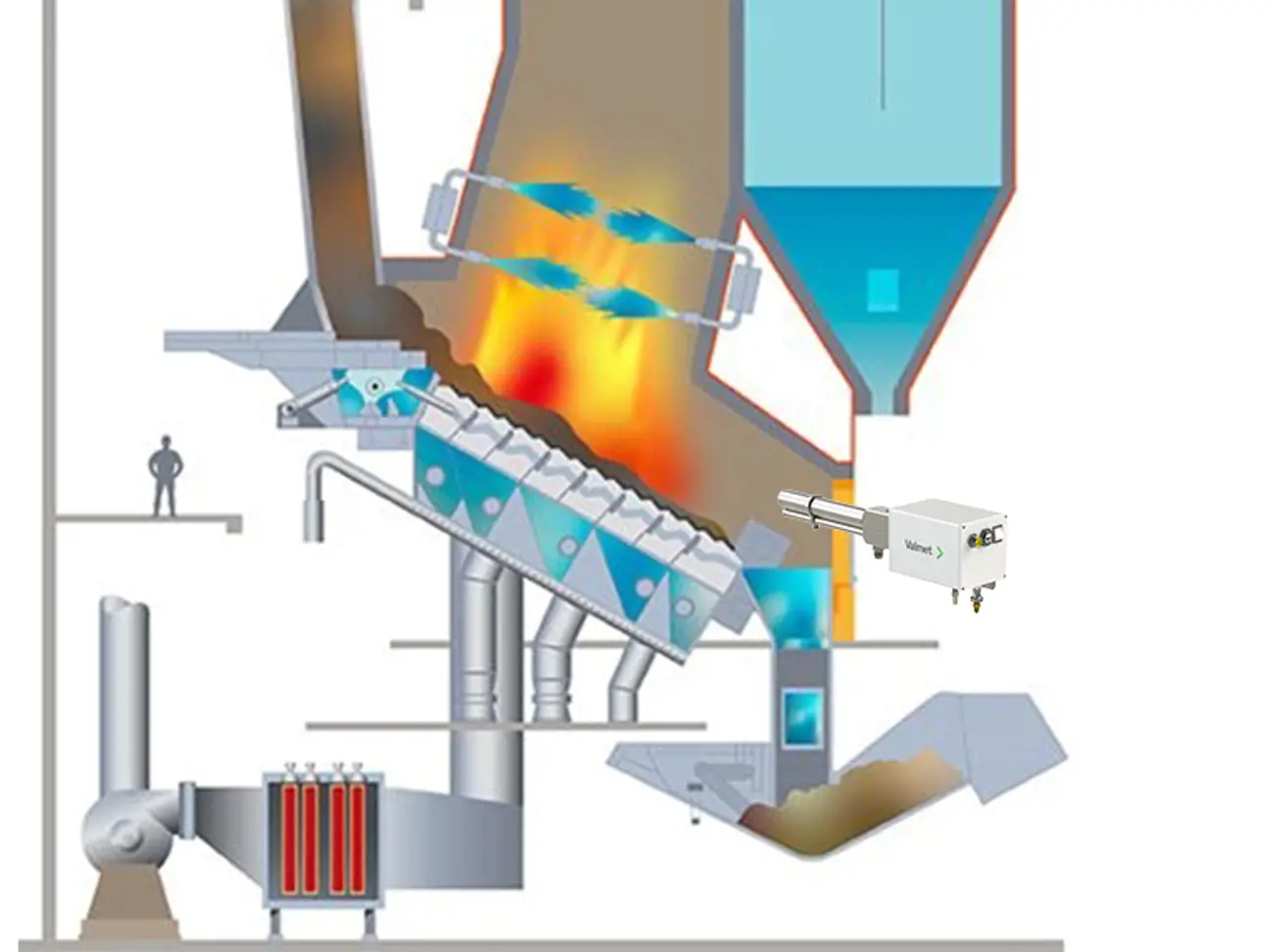

Valmet Grate Combustion Vision is a software application for the Valmet Furnace Visible Thermal Imaging System. With the grate combustion application, you have a highly specialized tool for increasing the performance of your waste-to-energy applications.

Maximize grate throughput - Continuously run at optimum capacity with clear insights into combustion behavior

Increase grate efficiency - Boost energy and reduce emissions through precise control and less downtime

Improve grate safety - Real-time monitoring helps identify and prevent safety risks

Integrated grate combustion control

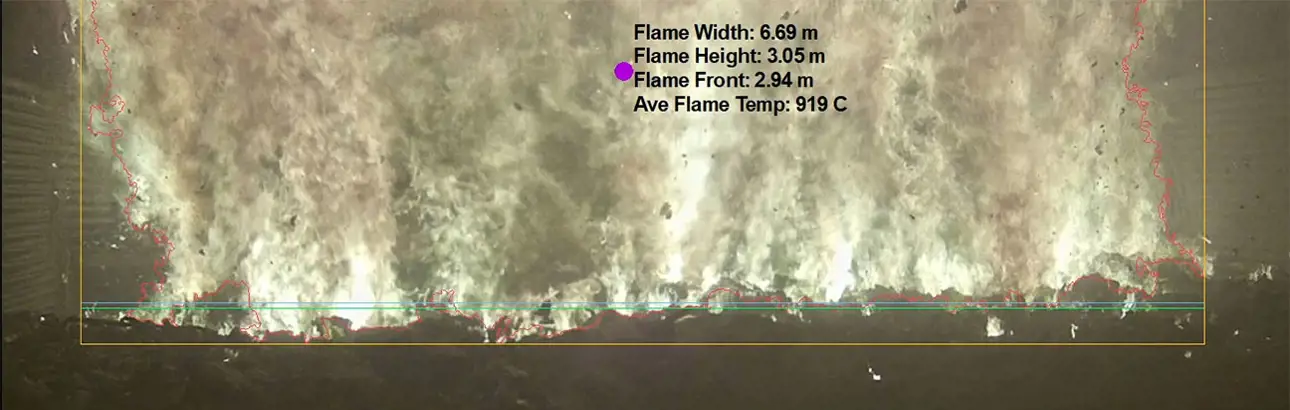

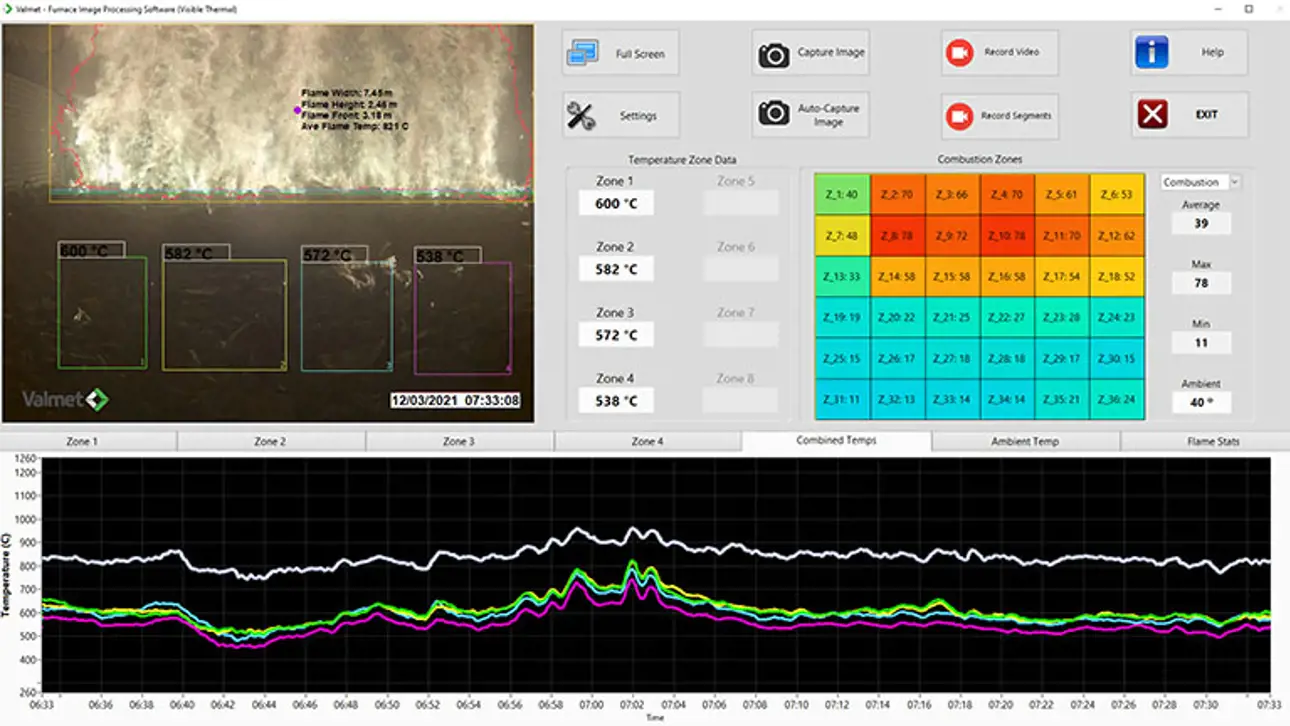

The Valmet Grate Combustion Vision application is uniquely created for moving grate boilers in waste-to-energy plants. The software application automatically detects the flame from high-definition imaging and measures the flame front location on the grate.

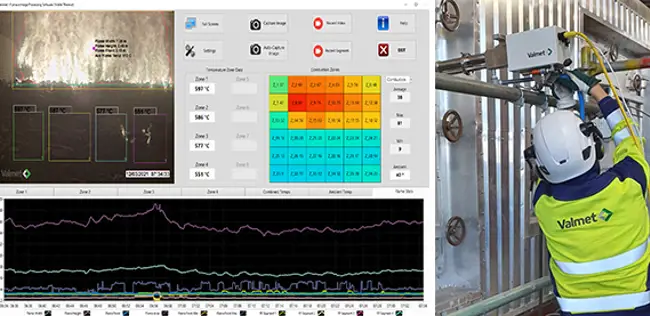

Real-time flame detection and monitoring improves flame control and helps operators optimize combustion to run the grate at ideal capacity and with less downtime. In addition to an intuitive display in the local control room, data from the Grate Combustion application can be easily transferred to the plant’s DCS.

Rugged optics for a clear view of the grate

The Grate Combustion application relies on the sturdiness of the Valmet Visible Thermal Imaging System. A robust, air-cooled camera system, it provides high-definition imaging and high-resolution thermal sensing for analysis of the combustion process. Digital-only data transmission improves reliability of video streams and filters out noise for better image quality.

Valmet Visible Thermal Imaging System and the Grate Combustion application provide a complete grate combustion control solution. The solution is purpose-built for hot and dusty environments to ensure durability and longevity.

Customizable to meet your operational needs

The robust algorithm used by the Grate Combustion application can capture key events under various types of process conditions. You have full control over what information overlays are used on the live image.

Designed for ease-of-use, dynamic parameters ensure there is little need for changes after initial calibration. Built-in video reporting automatically generates daily summaries. These can be compressed and emailed to specific recipients if desired.

Available measurements

- Average flame width, height, and size

- Up to 49 combustion zones with custom alarms

- Average flame temperature

- Up to 4 segmented flame fronts

- Flame front location and related statistics

Do you want to know more?

Contact us to request for more information, quotation or an inspection trial.

Contact us

Downloads |

||

|---|---|---|

| Valmet Grate Combustion Vision Brochure | ||