Screen baskets for tissue producers

Screen baskets with high removal efficiency of dirt and specs, high capacity and long lifetime with advanced chrome surface coating technologies

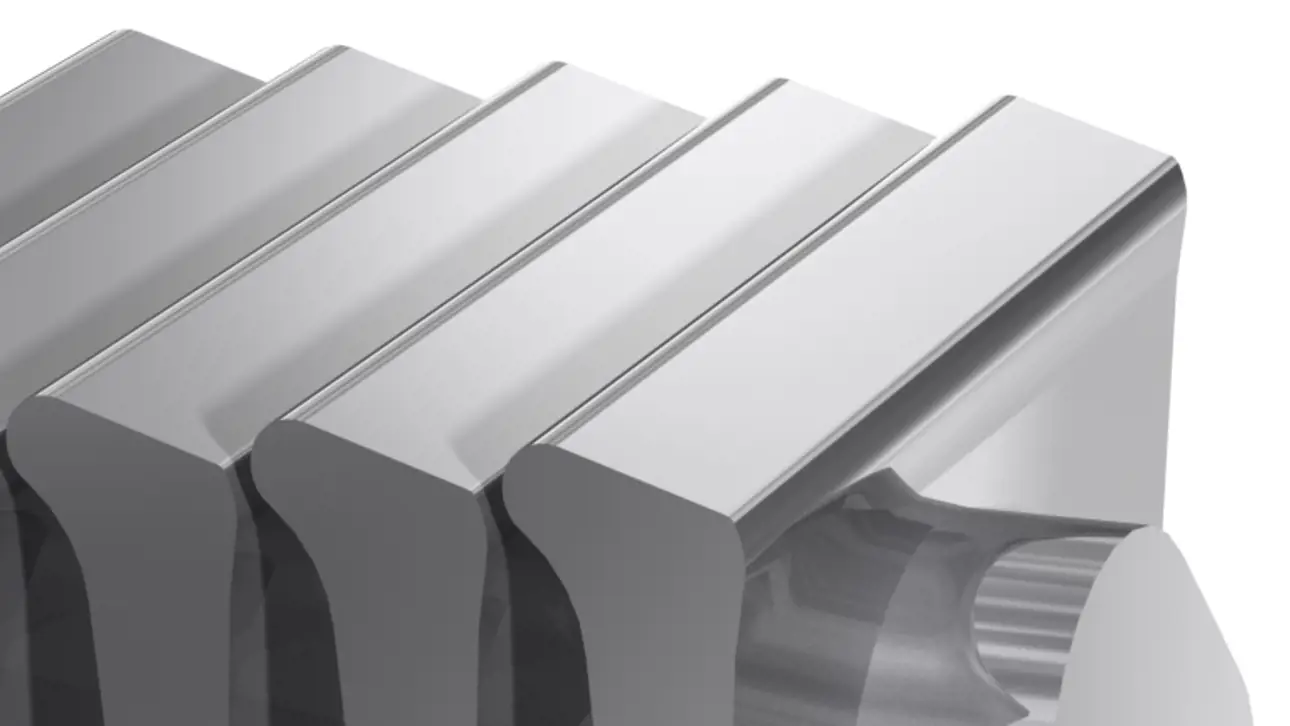

Screen baskets with accurate slots and high capacity to maximize screening efficiency in stock preparation applications and to gain high screening capacity in all applications. Wire profile selection will ensure an optimized screening process and fiber classification after screening to reach optimized fiber for tissue production. Enhanced chrome coating process will ensure a longer lifetime and string-free operation.

High screening efficiency

High capacity

Long lifetime

Improved runnability

Comprehensive product portfolio for your specific needs

Screen Basket ML

Durable structure for low to medium consistency applications. Industry-proven wire clamping technology, laser cut precision and a wide range of wire shapes.

High open area between retaining rings reduces flow resistance thus high flow capacity is achieved. Non-welded construction ensures accurate slot width for excellent shives removal efficiency over a long lifetime.

Read more about Screen Basket ML

Do you have any questions?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact us

Screen Basket VF

Optimized wire shape with accurate wire clamping technology gives high screening efficiency.

Laminar flow thru the screen basket in machine screening applications enables lower pressure drop that maximizes throughput and lowers the pumping energy needed in the approach flow applications.

Enhanced chrome coating of the basket ensures long lifetime and string free operation.

Screen basket D

Optimized profiling of the screen basket surface improves screening capacity by braking the fiber flocks and keeping the screening medium clear of plugging.

Valmet drilled screen baskets includes several sizes and types of perforation. Hole sizes range between 0,8mm to 10mm and holes can be made either cylindrical, conical or step drilled to reach targeted screening performance.

Read more about Screen basket D