Dewatering elements for tissue machines

Increased production capacity and improved quality with proper initial drainage

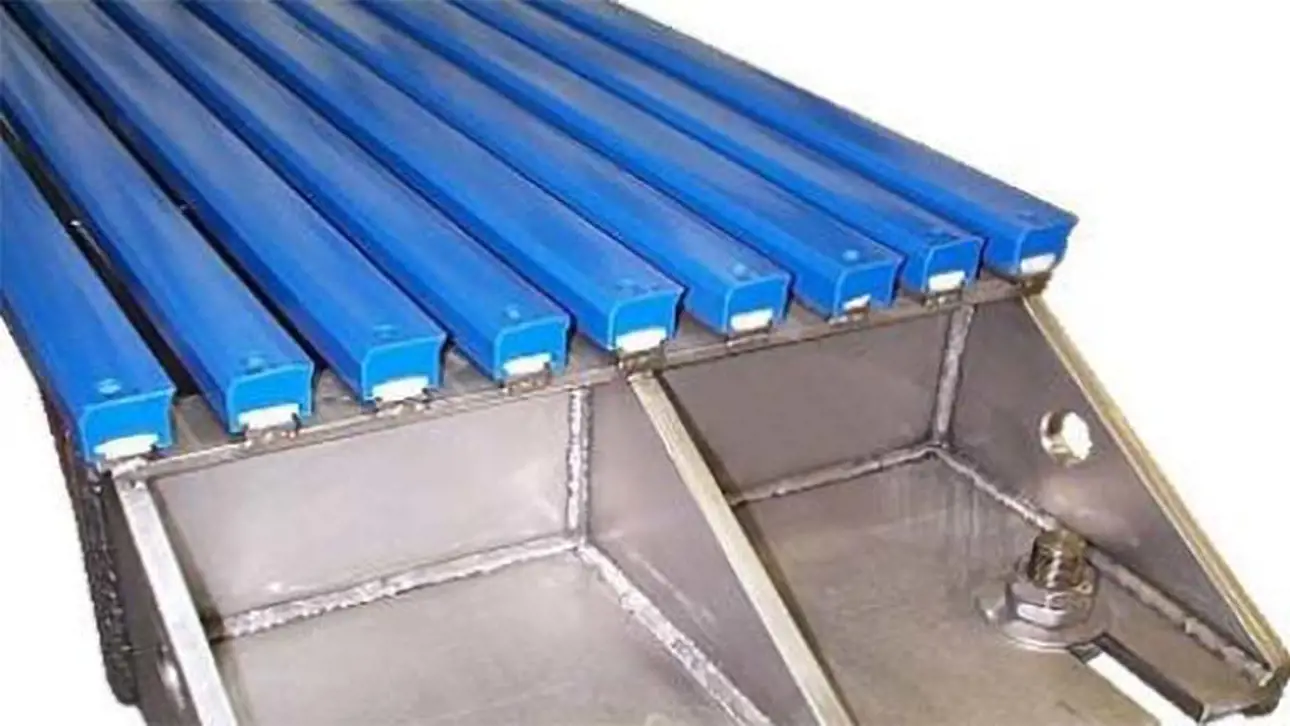

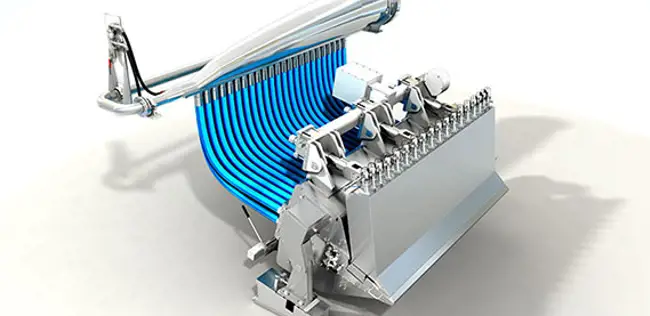

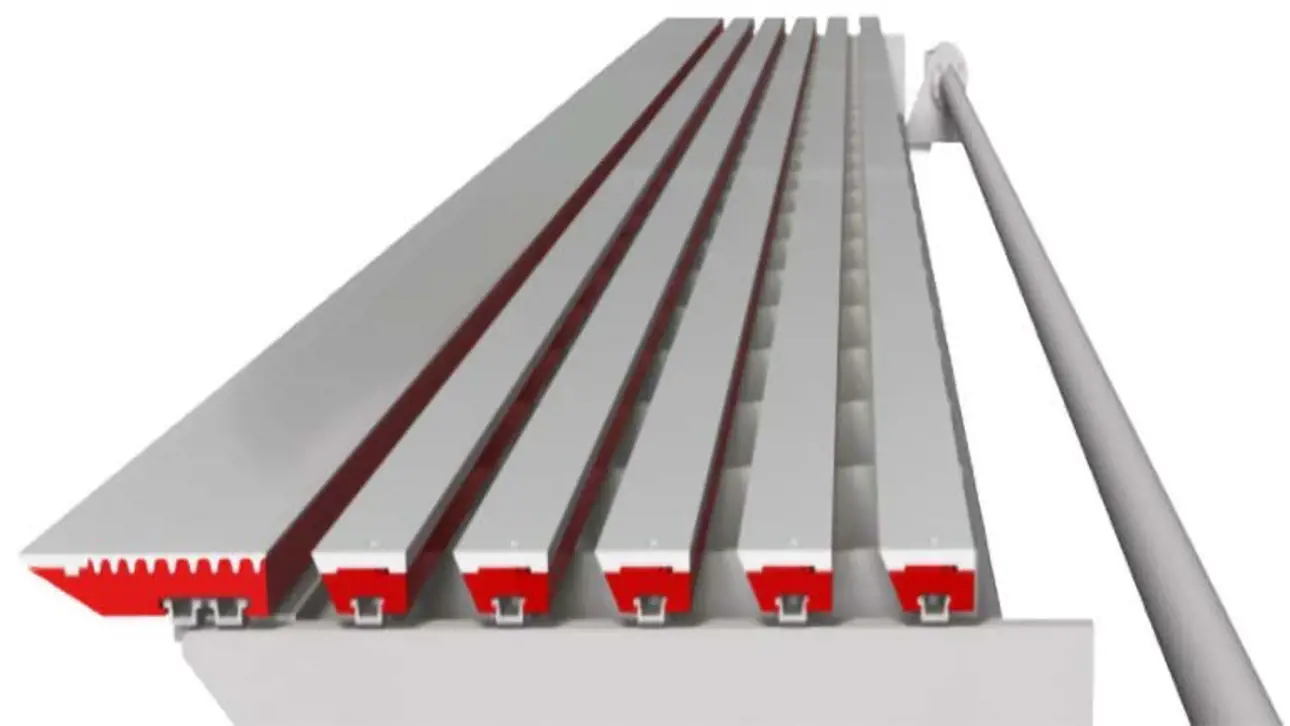

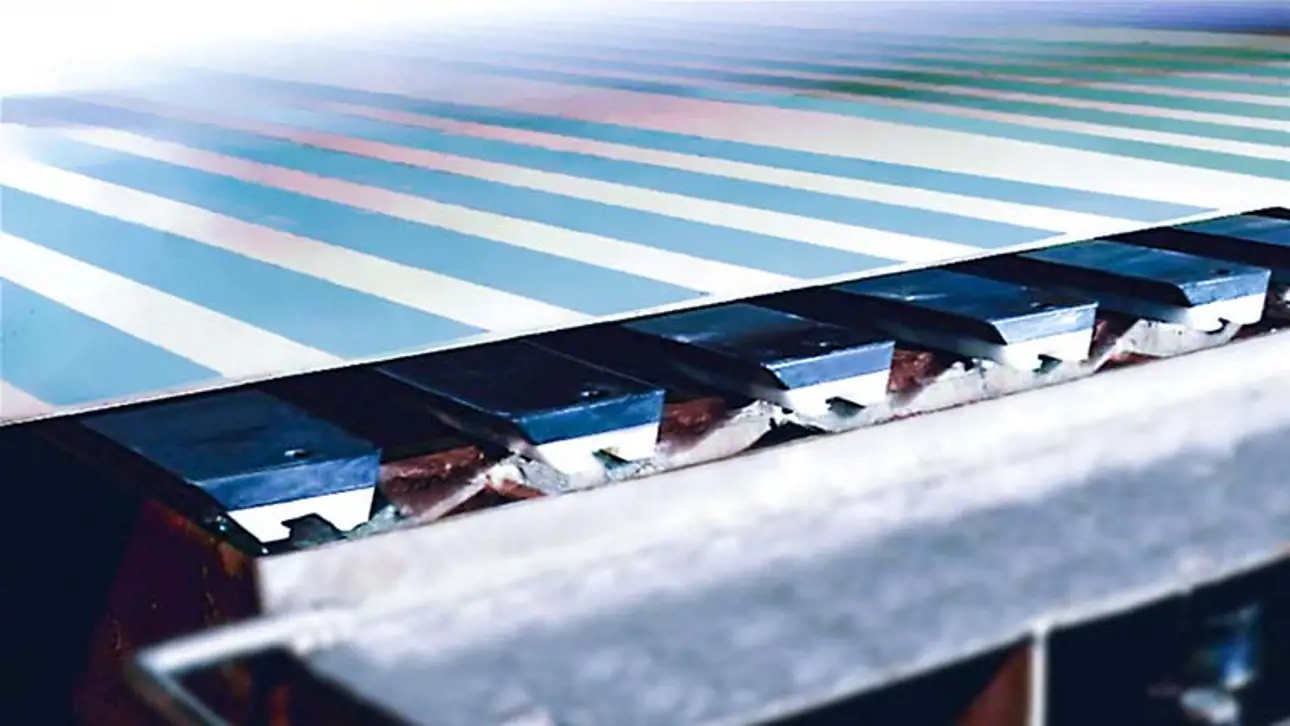

Dewatering equipment beneath the forming fabric helps drain water from the stock and conduct it away into the whitewater system. Proper initial drainage is important whether your priority is to increase production capacity or improve quality, or both. Valmet offers a comprehensive range of polyethylene and ceramic dewatering elements to suit virtually all positions and OEM machine configurations.

Easy and safe installation

Low friction

Fast turn-around time

Available for all OEM designs

Let us be your co-driver for success

Valmet solutions that combine parts and expert support will drive your production performances further. When you choose Valmet performance parts you are not just buying wear parts. You are also gaining greater availability, higher end-product quality and enhanced productivity.

With the combination of parts and expertise, we can together make a difference at every stage of your production process. We have increased production output and decreased total costs together by applying optimal performance parts to each position.

Any questions on your mind?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our co-driversCarefully selected materials for the longest lifetime and quality

Our carefully selected materials are used in different applications for different purposes. For example, we finalize our ceramics to very low surface roughness to make sure that fabric wear and power consumption is minimal.

|

Typical application/ Machine concept |

Ceramic material |

Lifetime |

Surface quality (Low power consumption, |

Investment cost |

|

Premium Aluminum Oxide | |||

|

Premium Silicon Carbide | |||

|

Silicon Nitride |

Dewatering Element Ceramic

- Wear resistant materials offer long and trouble-free operation and optimized dewatering

- Short delivery times

- Grinding and repairing service available

Dewatering Element Poly D

- Outperforms standard polyethylene by at least 4 times

- Offers tremendous wear resistance

- Valmet’s Poly D technology is a true polyethylene compound that does not suffer stress cracking or thermal shock damage

- Typical maximum machine speed < 760 mpm

- Supplied to 200 mills worldwide

Dewatering Element Poly S

- UHMW polyethylene suitable for many wet end applications

- Typical maximum machine speed < 460 mpm