Steam Separator PF

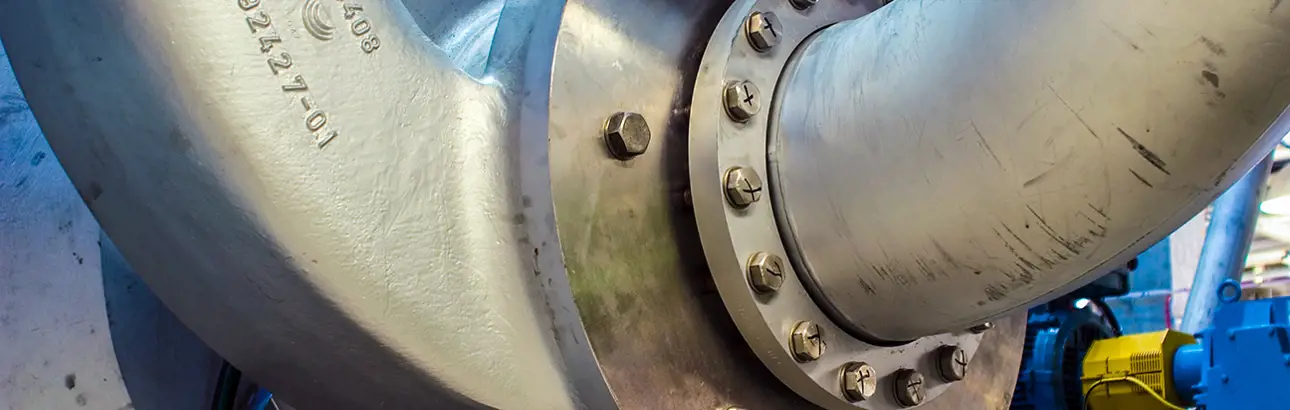

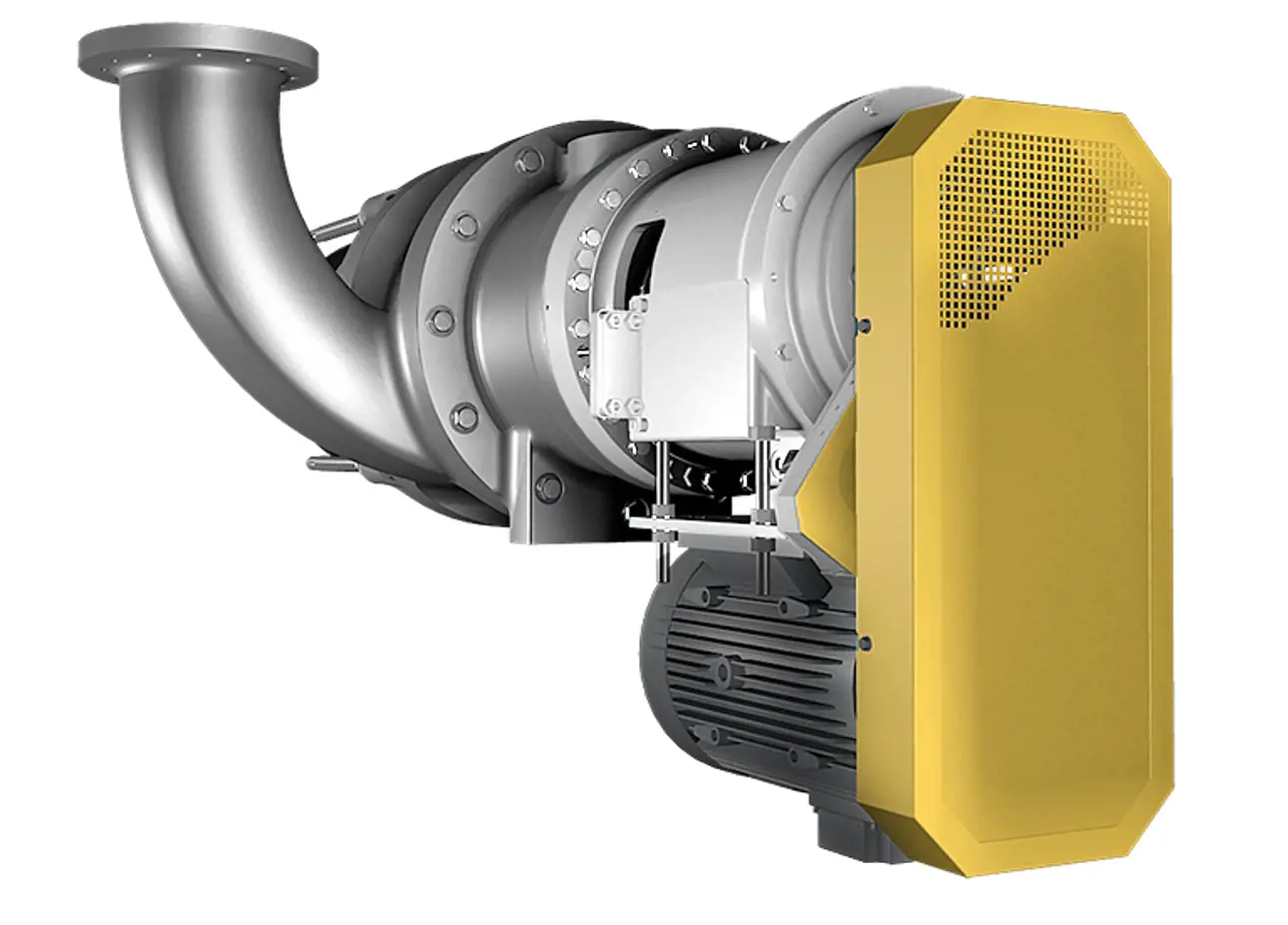

The Steam Separator PF is a mechanical steam separator that separates the steam from the fibers before they are fed into the second or third stage refiner.

This machine replaces the existing cyclone discharger and the refiner feeder and can be installed without modification of the refiner foundation.

Refiner models RGP 60/65, RGP 70/76 CD, RGP 82 CD, RGP 268 and SD 65 can be supplemented by this type of machine.

- Low installation cost

- Low maintenance cost

- Low load variations in the refiner

- No disturbances from a cyclone scraper

- Stable operation

- Short retention time

Material available for download |

||

|---|---|---|

| Steam Separator PF | ||

Our expertise is at your service

Our focus is to bring your performance forward. Get in touch with us through our website, or through your local Valmet office.

Contact us