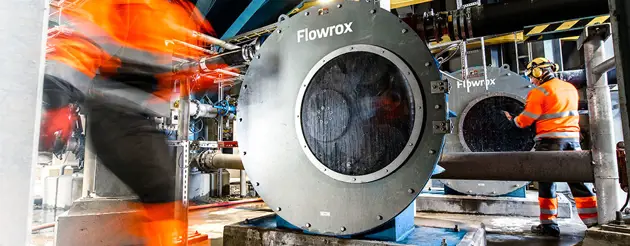

Flow control for slurry transportation

Flow control valves are expected to have the highest reliability and most trouble-free operation in slurry transportation lines where the valves are not continuously monitored. Whether it is concentration sand or concentrate transportation, Valmet's Flowrox™ pinch valves and knife gate valves offer the longest service intervals and ease of use. We have decades of experience in demanding slurry applications and have developed unique valves to outperform the standard products on the market.

Reliability

Durability

Experience in demanding slurry applications

Applications

The design and development of Valmet’s innovative high-quality slurry valves and pumps have been based on decades of experience and close cooperation with our customers in mineral processing. Valmet's flow control products and global service organization in more than 40 countries guarantee the reliability and performance of mining processes.

In tailings applications, Flowrox’s enclosed body pinch valves have been the most common type of valve body because its sealed design protects the sleeve from the environment, prevents premature weakening of the sleeve and makes it very safe to use.

Reference cases

- In an African iron ore mine, 250 mm/64 bar pinch valves have been operating for two years without a sleeve failure.

- A paste back filling plant in Africa has 150 mm/40 bar and 250 mm/25 bar pinch valves with a sleeve life of four to seven years.

Actuators

Compact, double-acting hydraulic actuators have been the primary actuators in tailings transportation and are designed for applications where high closing forces/fast operation (high working pressure or large valve diameters) are required. Electrical actuators are a low-cost solution for tailings pump discharge applications where high closing forces are required, such as large valve diameters or high operating pressures. The standard electric actuator has a built-in limit and torque switches, as well as a manual overtaking handwheel.

In the distribution of tailings, manual actuators are preferred when the presence of the operator is required in the operation of the valve. The valve’s fully sealed actuator mechanism provides full protection against dirt and corrosion. A reduction gear is provided which facilitates manual operation on valves with a larger diameter and higher operating pressures.

Downloads

Valves, pumps and services for slurry transportation

Flow control for different applications in mining and minerals processing