Flow control for metals refineries

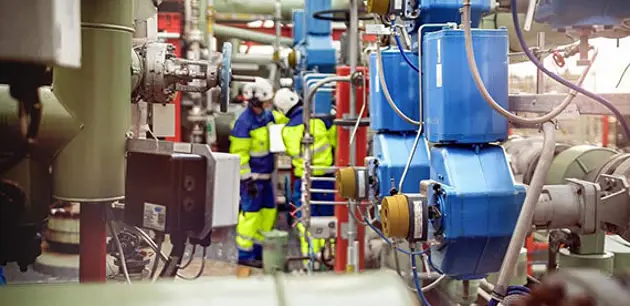

Our valves offering plays an important role in various metal refining processes for all commodities such as gold, copper, nickel, lithium and zinc. Whether your process is a hydro- or electrometallurgical plant or a smelter, our customers have trusted us with their flow control needs for decades. We offer extensive expertise and a wide portfolio of valve and pump solutions.

Reliability

Industry-proven efficiency

Industry knowledge and expertise

Applications in metals refineries

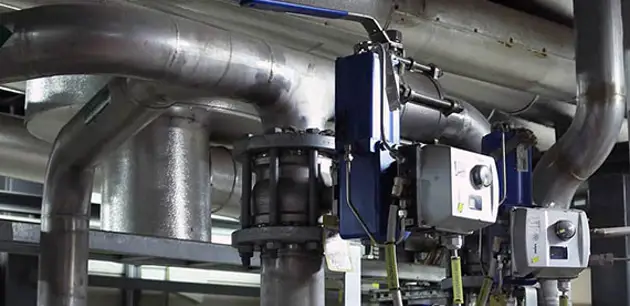

You will find a wide array of applications in metals refineries: Each plant needs the standard water and air services. Depending on the process technology, there can be a wide array of needs. Smelters operate in high temperatures requiring valve products that can withstand the heat. Impurities are often present in the gases that run through the pipelines in smelters.

Hydrometallurgical plants need a variety of chemicals and gases in the process of refining a concentrate into a metal. Some of these media are hazardous, both for the people who operate the plant and for the environment. This means that fugitive emissions from valves need to remain at zero.

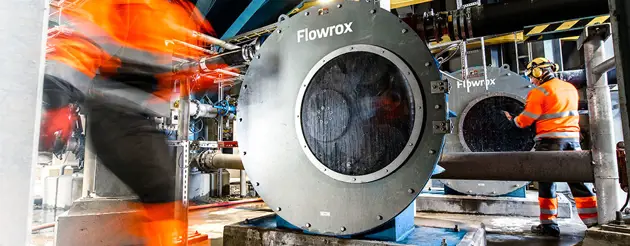

One of the most demanding process in the metal refining process is an autoclave operation. These industrial-scale pressure vessels operate at high temperatures and pressures, with abrasive and often acidic media. Applications range from slurry feeds to slurry discharge, utility feeds, and a pressure control or vent line. When it comes to demanding operating environments, no detail is too small to consider when selecting the most suitable construction materials, designs and planning for optimized valve maintenance.

Our products provide industry-proven efficiency and reliability based on well-thought-out designs and material selections paired with dedicated service expertise. Full product assemblies with service coverage across their lifecycle, all from one responsible source, ensure optimized performance.

Downloads

Valves, pumps, valve automation and services for metals refineries

Flow control for different applications in mining and minerals processing