The best flow control solutions for an evolving pulp & paper industry

Oct 19, 2022

Valves play a vital part in pulp, paper, board and tissue production. As efficiency, reliability, sustainability, safety and profitability demands on the processes themselves have grown over time, the valve technologies too, have developed immensely. We are an active participant in driving modern flow control solutions forward to best serve our customers.

The role of valves as a part of the process is important in many ways. While accurate flow control has a direct impact on the quality of the end products, perhaps more importantly the right valve selection can help improve the efficiency and sustainability of the process itself significantly. This of course also means creating savings and lowering overall costs. Valves, especially when paired with intelligent control and increased levels of automation, can make a real difference.

Valmet today, is in a unique position, after the addition of our flow control solutions to the overall offering. With the industry’s strongest valve portfolio complementing Valmet’s process technology, advanced automation and expert service offering, we can truly provide our customers added value that far surpasses what any other supplier can offer today – all from one reliable source.

History of industry leadership

Valves may not be thought of as central components of the process, but there are literally thousands of valves involved in the journey from wood to pulp to finished end product. Today, still more than 75% of the worlds pulp passes through at least one of our valves during production. More than 60 years in the service of the pulp and paper industries may also have a lot to do with it. Also, our offering of world-renowned valve solution from product brands such as Neles™, Jamesbury™, Neles Easyflow™, Stonel™, Valvcon™ and Flowrox™ enjoys a strong reputation of quality, accuracy, safety and reliability.

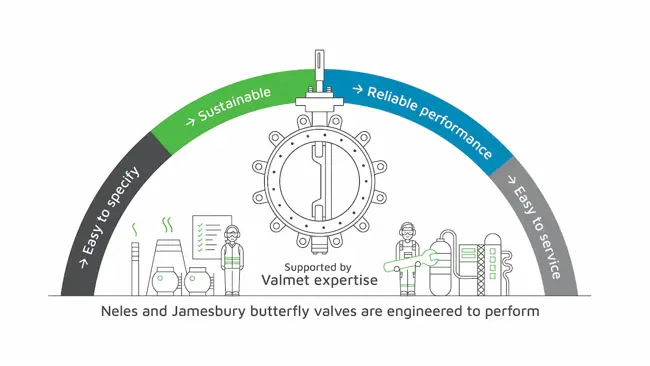

We have always taken pride in our position as an industry trailblazer, when it comes to valve technologies used in the pulp, paper, board and tissue processes. Our flow control portfolio consists of all the typical valves for control and on-off use, including ball, butterfly and segment valves. Additionally, our industry-leading offering also includes a wide range of accessories, intelligent devices and software products, all engineered to meet each individual pulp or paper mill’s needs and challenges.

Innovation has always been a key driver for product development. There are many pulp and paper -specific flow control products in use today, that have their origins on our desks. Such innovations over the years have included the capping valve for batch cooking, a high-consistency valve for bleaching, a valve for basis weight control, ceramic ball valves for erosive applications as well as a host of intelligent valve controllers to name a few.

Meeting modern industry demands

Every day, I see first-hand how our industry-leading valve solutions are helping improve business performance in mills around the world. Our solutions are helping customers maximize process efficiency, availability and performance, all while improving the safety and reliability across the lifecycle of the entire mill.

The rising cost and growing scarcity of both raw materials and energy will continue to drive the need for improving process performance and efficiency in the future. Also, we have seen that despite what many thought, the pulp, paper, board and tissue segment has grown steadily, and will continue to grow.

The reduction in demand for printing and writing paper in this digital era has not stopped the growth in demand for other pulp-based products. If anything, this more environmentally conscious society we live in has driven the demand for non-plastic alternatives for many traditional products from packaging materials to drinking straws. We are even seeing the emergence of new pulp-based textile fibers.

A versatile offering is key

So, while the basic functions of valves in different parts of the papermaking process may have stayed largely unchanged over time, the growing demands related to efficiency, profitability, safety, reliability and sustainability have been active drivers for product development and R&D.

Our improved globe valve offering continues to deliver excellent control performance in high-pressure applications such as boilers in operation at mill powerplants. At the same time our latest versatile butterfly valves are proving to be an optimal solution for a host of end uses thanks to their modular yet robust and reliable design and construction.

The continuing developments in digitalization, automation and networking of smart devices have been one of the biggest game-changers in industry as a whole. This is also true in the pulp, paper, board and tissue industries. The virtually real-time control and monitoring capabilities that come with smart devices such as our NDX valve controllers are the modern way to ensure process quality and performance. With seamless connectivity and compatibility with Valmet’s vast automation offering, the customer benefits are further amplified.

Service keeps getting smarter

Predictive maintenance is the best way to avoid problems and ensure reliability and optimized process uptime. It is made possible by accurate real time data used to fine tune a predictive maintenance plan based on decades of application knowledge, service experience and statistical analysis of service records. The latest development in further integrating intelligence to improve service planning, the Valmet Industrial Internet (VII), will be made available to the first customers still this year (2022).

“It’s about much more than just data on current valve performance. It incorporates our vast installed base data, decades of service experience, diagnostics, device service history and current performance. So basically, everything you need to plan service and maintenance operations on a device and mill level,” explains Sami Nousiainen, Vice President, Service and MRO Business unit, of Valmet’s Flow Control Business Line.

He further emphasizes that the ability to harness our long-running pulp and paper industry experience and understanding to ensure the best available services anywhere in the world, puts Valmet in a strong position. “We combine the latest technologies with the strongest industry experience to provide our customers a level of service that gives them a measurable competitive edge in business.”

A continued commitment to the industry

Our state-of-the-art valve production facilities around the world, and our conveniently placed service centers, ensure that we can provide the best in both products and services to all our customers worldwide. We provide flow control solutions and a wide range of lifecycle services for both greenfield projects and the many conversion projects from paper to board production.

Our Flow Control Business Line is partnered with existing mills all across the globe. At the same time, we are happy to see so many new mill projects starting up – not just across Northern and Central Europe, but also in the Americas and across China and Asia Pacific. Just this year, we delivered well more than 3,000 individual valves to Metsä Group’s new bioproduct mill project in Kemi, Finland. To help collect performance data and optimize future valve service and maintenance operations a majority of the delivered valves were fitted with our intelligent valve controllers.

We are thrilled about being a part of projects like this. With the continued demand for pulp, the shift from paper to board and tissue and the emergence of new innovative pulp-based products, this is an exciting industry that we want to be a part of developing and serving.

Subscribe to our newsletter

Subscribe now to our 'Go with the flow' newsletter and receive the latest insights directly to your email.

Subscribe