Sizer consumables for board and paper machines

Outstanding paper quality with Valmet Sizer Consumables

Sizer consumables play an important role in film sizing and coating. When you choose products that are optimized for your machine and process, you chieve outstanding paper quality, maximized production capacity and a stable process. Our consumables have excellent wear resistance – meaning less downtime and fewer consumables used, and, thus more production and lower costs.

Valmet has a thorough understanding of the papermaking process, including surface sizing and film coating. Tens of thousands of rods, rod beds and sealing blades have been made for customers worldwide in more than 25 years. Proven production concepts, carefully selected raw materials, and internally developed special manufacturing methods ensure the consistently high quality of all consumables.

Full offering for all sizing and coating needs

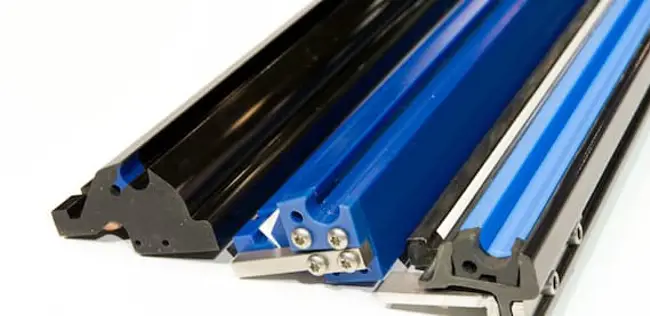

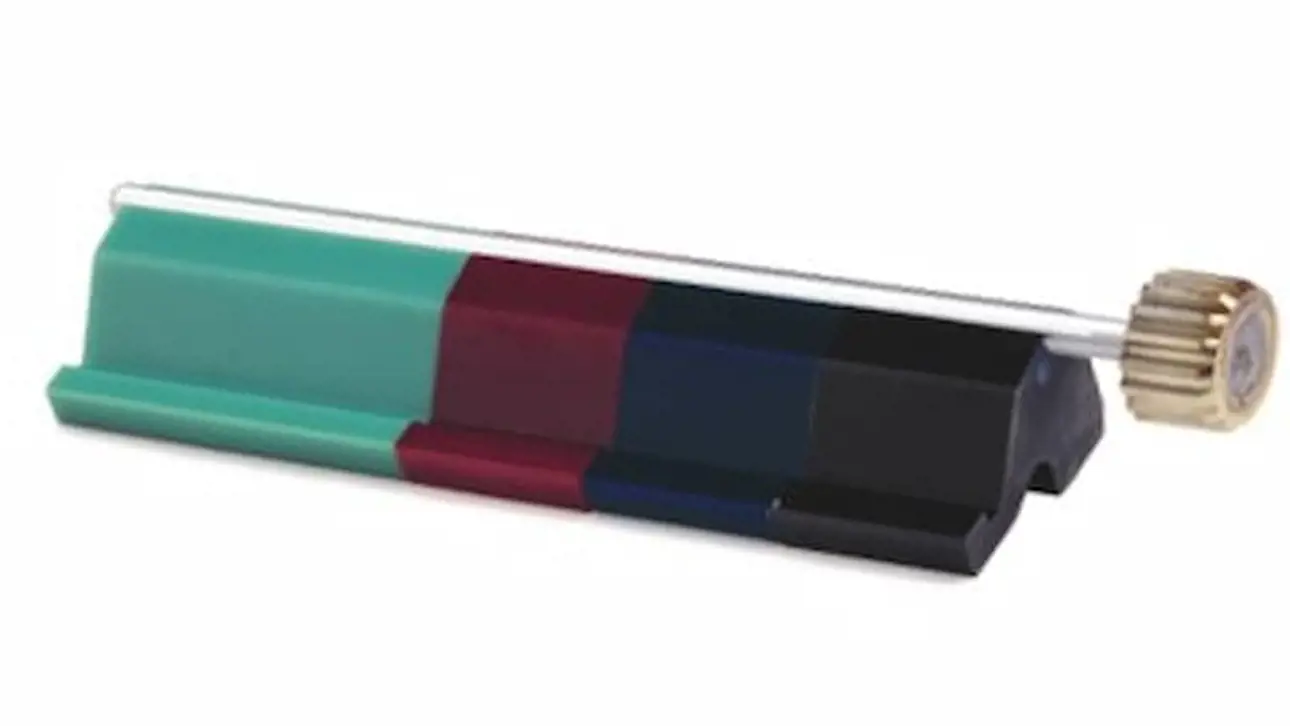

Valmet Applicator Rods

Over the years we have developed top-notch raw material know-how and our own steel specification. Also, our own metal laboratory for quality control and product development ensure that we only use high quality raw material free of defects.

We have developed inspection methods and special equipment developed to secure consistent production processes and product quality.

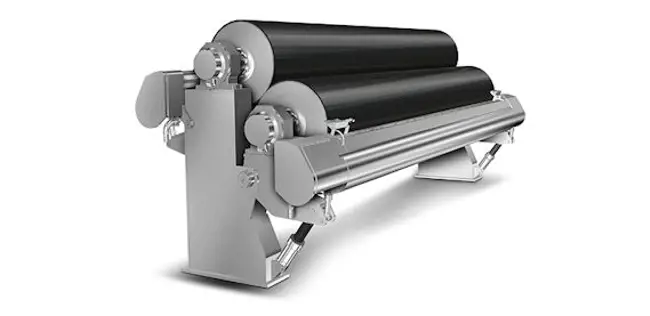

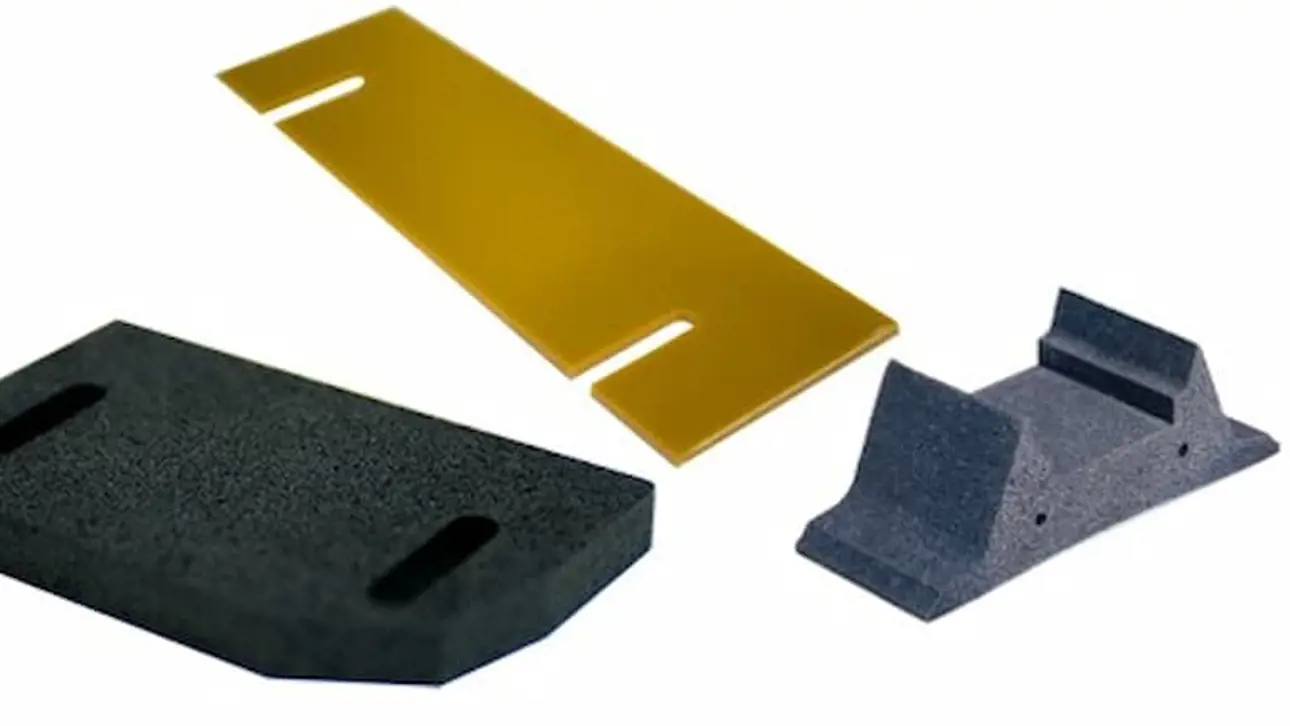

Valmet Rod Beds

Rod beds are characterized by three attributes: reliability, performance and reusability. By reliability we mean better and more stable runnability for your process. Performance means long lifetime with excellent results, while reusability means less waste and significant cost savings.

Other sizer consumables

By using the OEM accessories, you ensure operational excellence for film sizing and coating of both paper and board.

We are close to you

Valmet has an effective chain of warehouses and logistics centers worldwide, so we promise fast and smooth deliveries for our sizer consumables. We serve our customers through the global customer service network either on site or remotely.

If you want to take your performance even further, we offer continuous support with consumables agreements. To find out more, click to see video.

Do you have any questions?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact usExplore related services

Our optisizer sizing solutions