Want to know how superior product design is achieved? High quality and robust design reflect on the reliability and performance of valves. We interviewed Tommi Bergström, Manager, Engineering Analysis, about the design process behind the new modular butterfly valve platform.

What was the target of the new design?

The customer benefits and requirements were the design basis of the new versatile butterfly valve series. We wanted to achieve reliable performance:

- Reliability

- Endurance in various conditions

- Rigid and robust design

- Performance

- Shutoff tightness

- Low fugitive emissions

- High flow capacity, energy-efficient design

How were these requirements achieved in the design phase?

We focused on simulations in the design work. They provided accurate and reliable results, together with high-level, state-of-the-art design automation.

We also utilized known working principles; we calibrated simulation models and compared them with laboratory measurements. The final verification was done with laboratory measurements.

How did you utilize digitalization and virtual prototypes?

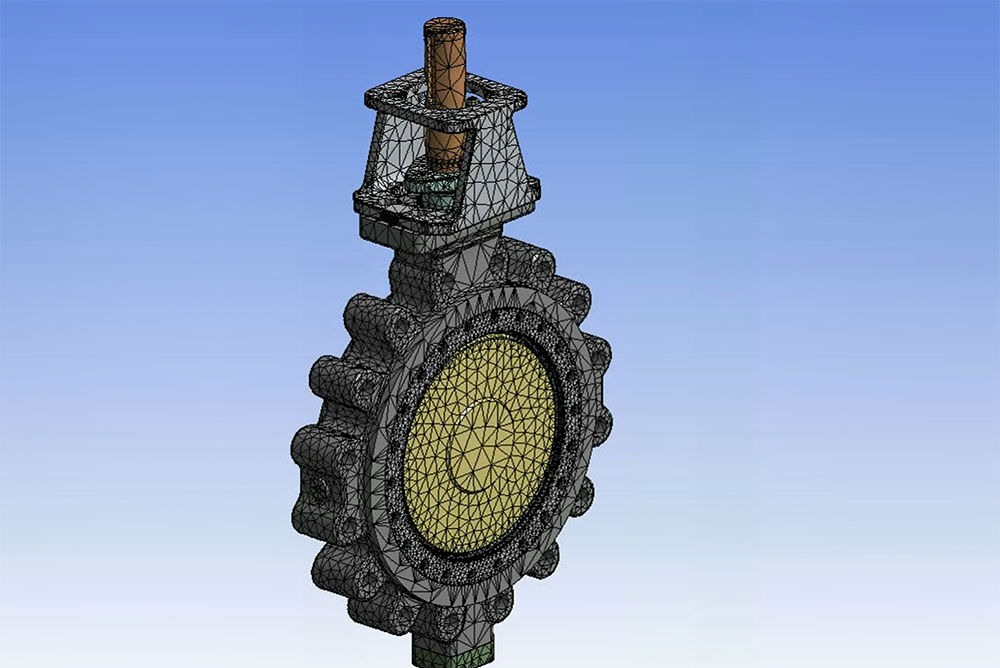

Digitalization of the design was the key in the design phase. We started from digital concepts, followed by digital prototypes and validation. We ran several thousand simulations to study different operating scenarios for the designs. Finally, we selected the most feasible designs.

After the concept phase, the next step was to develop a virtual prototype and optimize the design for different aspects, such as reliability and high flow capacity.

Creating digital and virtual prototypes is an important part of the valve design phase

What has been done in practice?

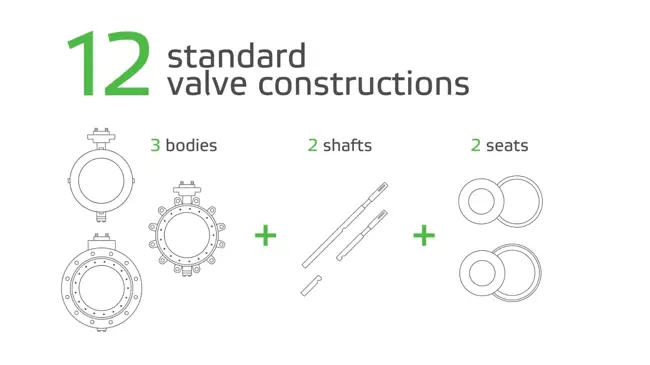

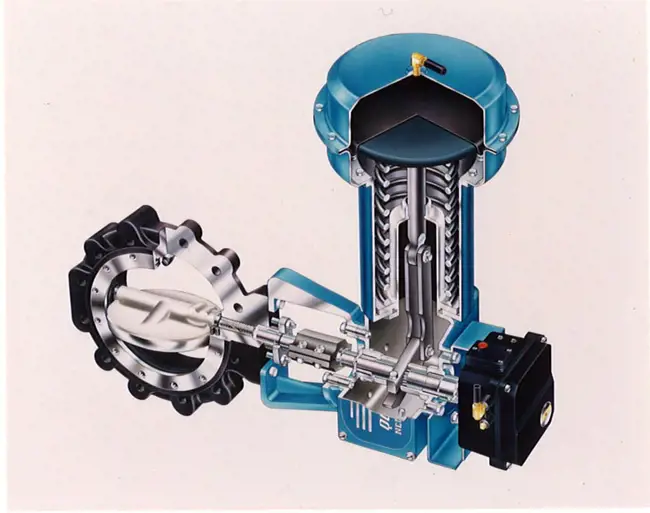

The design of the new butterfly valve is optimized to give the best performance in all given scenarios.

The different scenario simulations enabled us to predict the future performance of the valve in different scenarios, which adds reliability and robustness to the design. The design of the new butterfly valve is optimized to give the best performance in all given scenarios.

In the simulations, we combined and coupled different physics – from structural to heat transfer and fluid dynamics, including cavitation and erosion predictions. All performance requirements were taken into consideration at the same time. As an example, high capacity means smaller pressure losses in a fully open position. Thanks to the energy-efficient design, our customers can achieve cost savings.

How was the design validated?

The final validation and required type testing were done in the laboratory. Thus, we can be sure that the product fulfills all customer requirements.

The text has been updated in April 2022, due to the company name change to Valmet.