We believe that safe products can only be made in safe working environments. Just as we design our valves to be safe for you to install, service and operate, we pay careful attention to the safety of our own production processes.

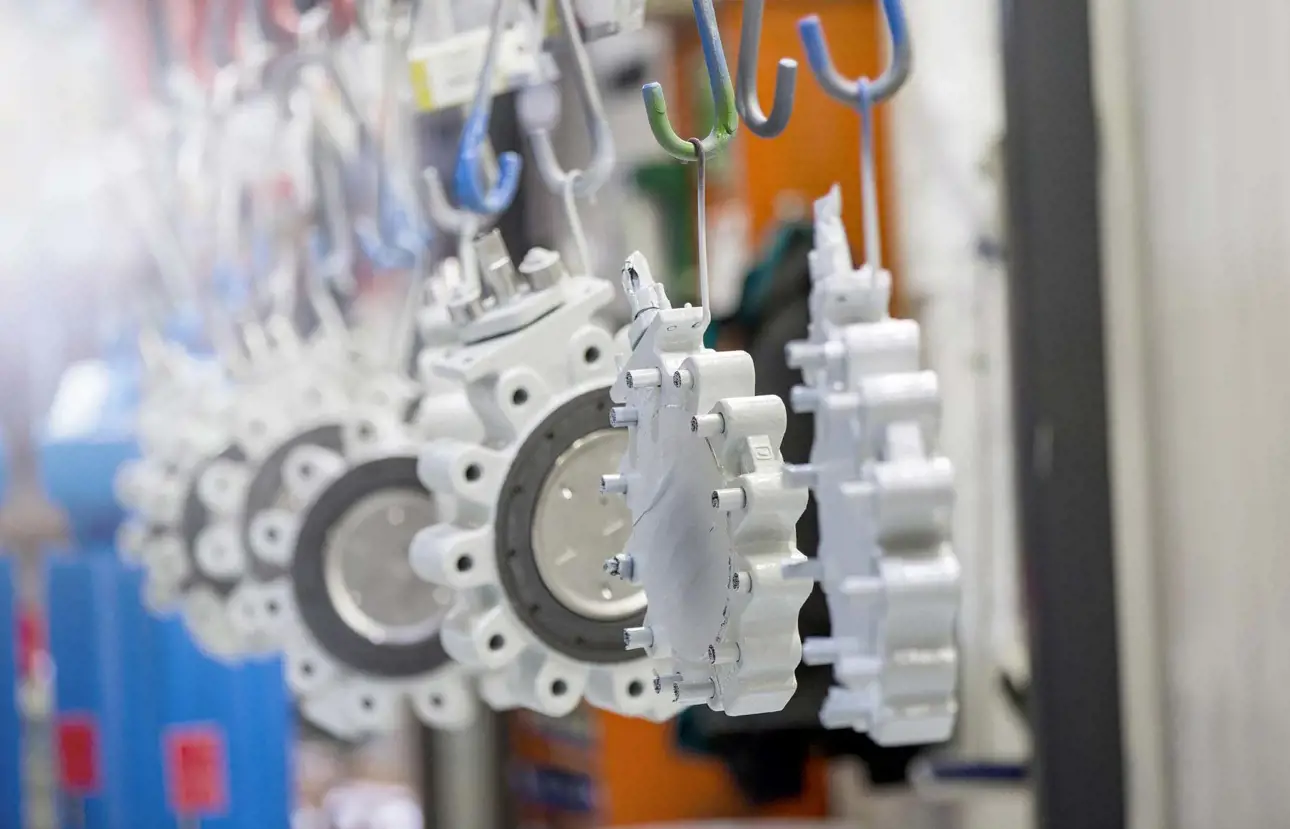

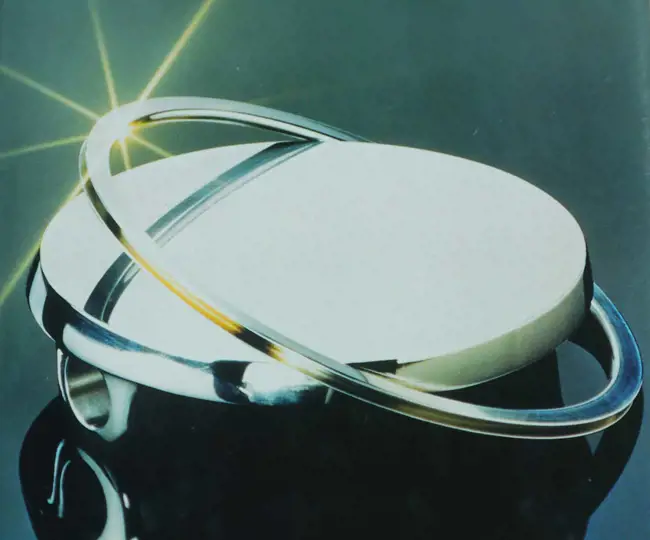

Looking at a product development project such as that of our versatile butterfly valves from the perspective of production, we believe that safe and reliable valve products need to come from a safe production site. Before starting the production of a new product, we start by reviewing the entire production process. A thorough video analysis was carried out on-site and development points identified. We made considerable new investments into the machining process. In a case like this we also always pay attention not only to the efficiency of production and assembly, but health and safety aspects such as ergonomics and safe lifting. We look at the process behind each and every component as well as the assembly of the ready valve that gets shipped out to the customer. The quality of the process is reflected in the quality of the final end product.

The quality of the process is reflected in the quality of the final end product.

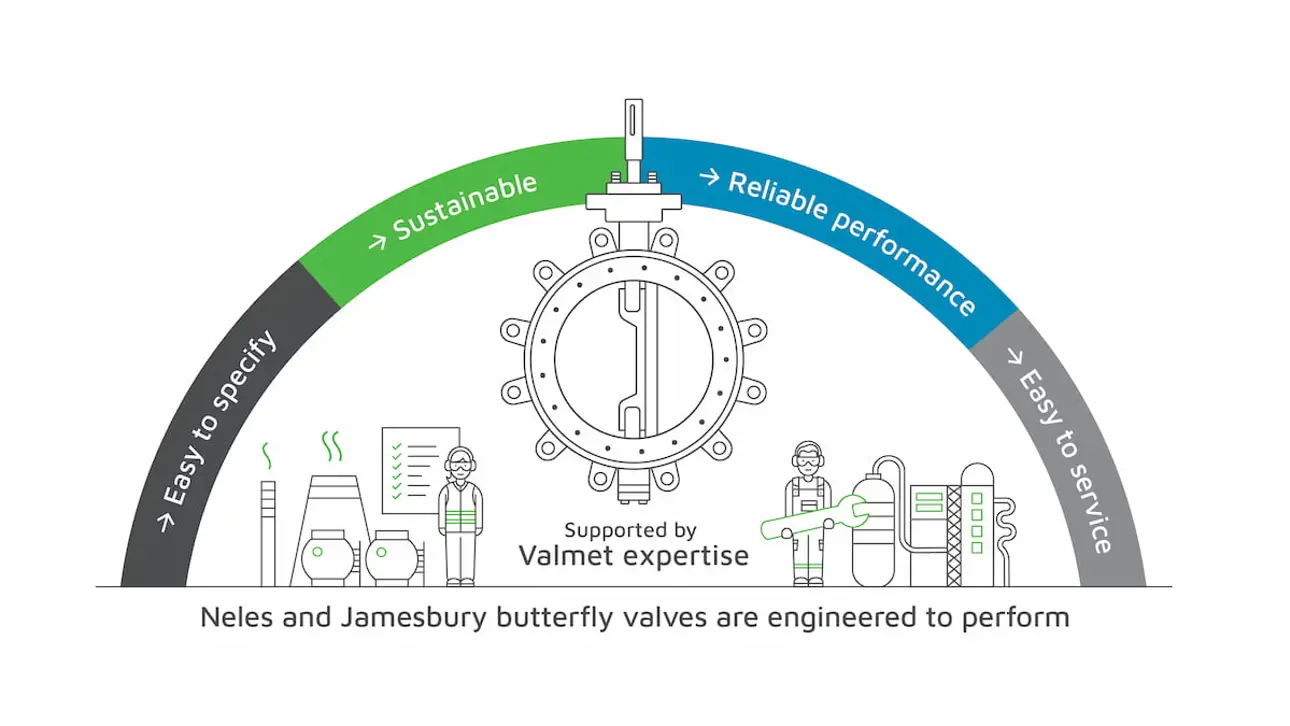

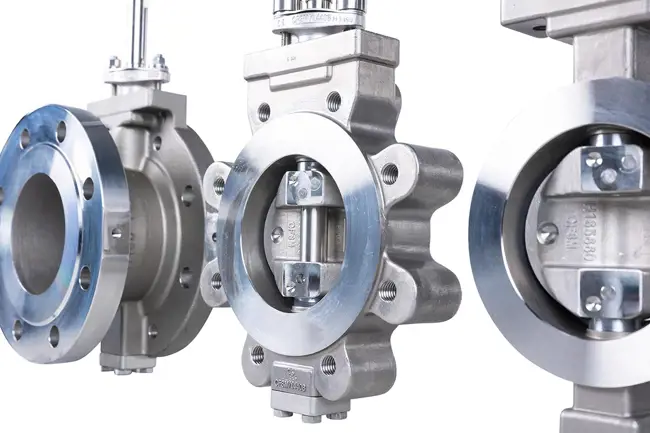

Our butterfly valves have been designed with performance in mind. At the same time manufacturing has also been in focus throughout the engineering process. This type of method engineering has been a part of development since the very beginning. This approach has resulted in a number of new innovations and approaches. One such feature that serves everyone from assembly to installation and maintenance has been the inclusion of well-thought-out lifting supports on all valves weighing more than 20 kg. We also aim to always minimize the amount of heavy lifting involved with assembly.